Laser brazing method for TiNi (titanium-nickel) shape memory alloy and dissimilar light metal

A memory alloy and light metal technology, applied in the field of ultrasonic-assisted laser brazing connection, can solve the problems of affecting shape memory performance, low welding temperature, not yet seen, etc., to eliminate the influence and improve the mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

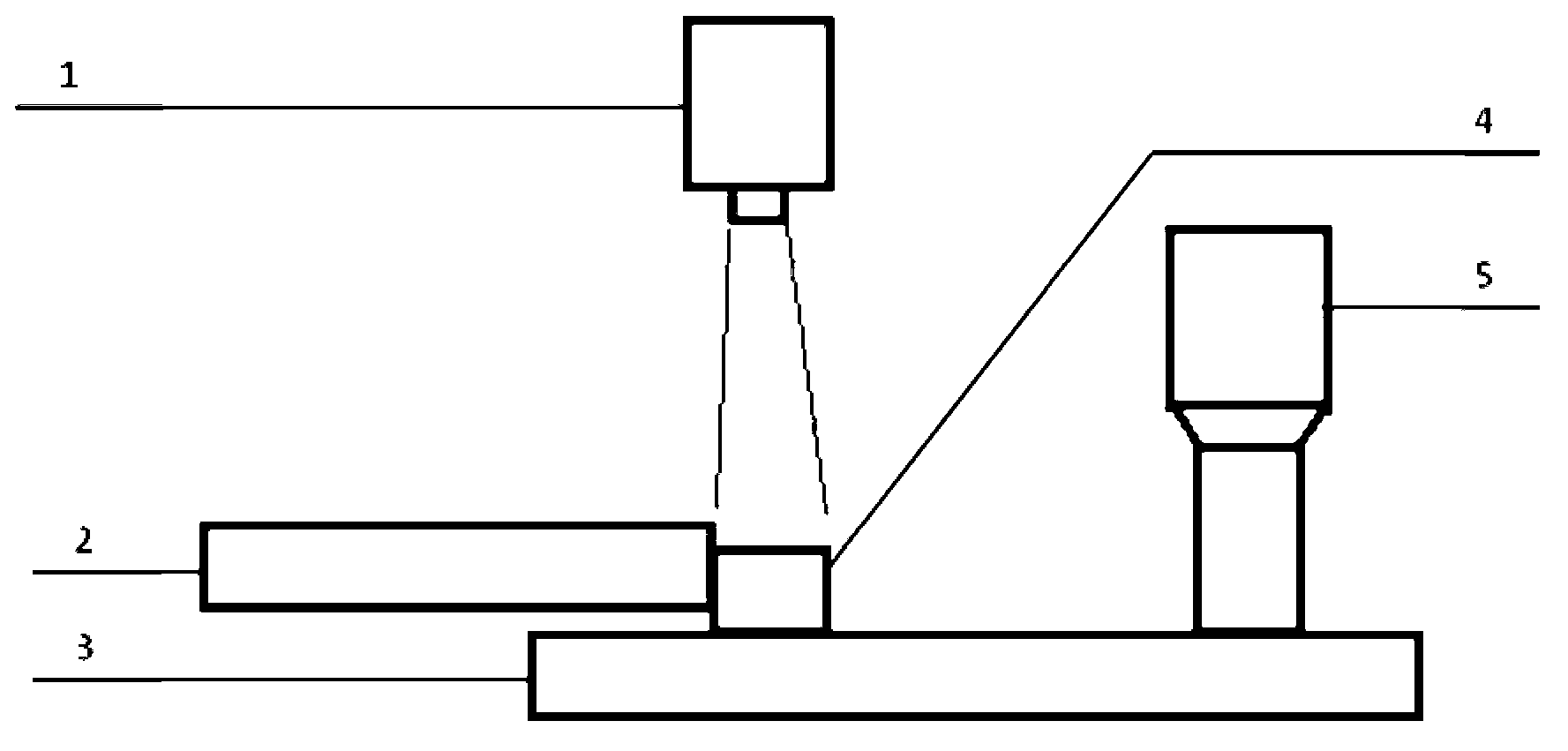

Image

Examples

Embodiment 1

[0020] 1. Cut the TiNi shape memory alloy and TC4 titanium alloy into strips of 50mm×10mm×3mm respectively, polish them flat and have a metallic luster on the surface, put them into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe them and dry them;

[0021] 2. After polishing the Al85Si10Zn2Ag2Ti1 solder with a size of 10mm×3mm×3mm on sandpaper to make it smooth, put it into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe it and dry it;

[0022] 3. The welding adopts the lap joint method. The TC4 titanium alloy is used as the upper plate, which is lapped on the TiNi shape memory alloy of the lower plate. Turn on the laser, aim the light spot at the solder, and adjust the laser heat input power to 500W. After the solder sags and melts, the laser continues to heat for 4 minutes, and ultrasonic vibration is applied to the edge of the base metal of the lower plate. The ultrasonic time is 1.0s to promote the filling of the solder. After the ultrasoni...

Embodiment 2

[0025] 1. Cut the TiNi shape memory alloy and TC4 titanium alloy into strips of 50mm×10mm×3mm, polish it flat and have a metallic luster on the surface, put it into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe it and dry it;

[0026] 2. After polishing the Al83Si12Zn2Ag2Ti1 solder with a size of 10mm×3mm×3mm on sandpaper to make it smooth, put it into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe it and dry it;

[0027] 3. The welding adopts the lap joint method. The TC4 titanium alloy is used as the upper plate, which is lapped on the TiNi shape memory alloy of the lower plate. The solder block is placed on the base material of the lower plate and close to the gap between the upper and lower plates. For quasi-soldering material, adjust the laser heat input power to 500W. After the solder material collapses and melts, the laser continues to heat for 4 minutes, and then apply ultrasonic vibration to the edge of the base metal of the lower pla...

Embodiment 3

[0030] 1. Cut the TiNi shape memory alloy and TC4 titanium alloy into strips of 50mm×10mm×3mm, polish it flat and have a metallic luster on the surface, put it into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe it and dry it;

[0031] 2. After polishing the Al80Si10Zn6Ag2Ti2 solder with a size of 10mm×3mm×3mm on sandpaper to make it smooth, put it into an alcohol solvent for ultrasonic cleaning for 15 minutes, wipe it and dry it;

[0032] 3. Use TC4 titanium alloy as the upper plate, lap it on the TiNi shape memory alloy of the lower plate, place the solder block on the base material of the lower plate, and close to the gap between the upper and lower plates, turn on the laser, align the light spot with the solder, and adjust the laser The heat input power is 500W. After the solder slumps and melts, the laser continues to heat for 2 minutes, and the ultrasonic vibration is applied to the edge of the base metal of the lower plate. The ultrasonic time is 1.0s to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com