Method for compositing high-entropy brazing filler metal coating laser brazed ceramic and metal

A technology of composite solder and high-entropy alloy, which is applied in the field of composite high-entropy alloy solder coating brazing ceramics and metals, can solve the problems of affecting the content of metal components in the brazing seam, reducing joint strength, and long brazing time, etc. Achieve the effect of improving welding quality, small joint deformation and short heating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

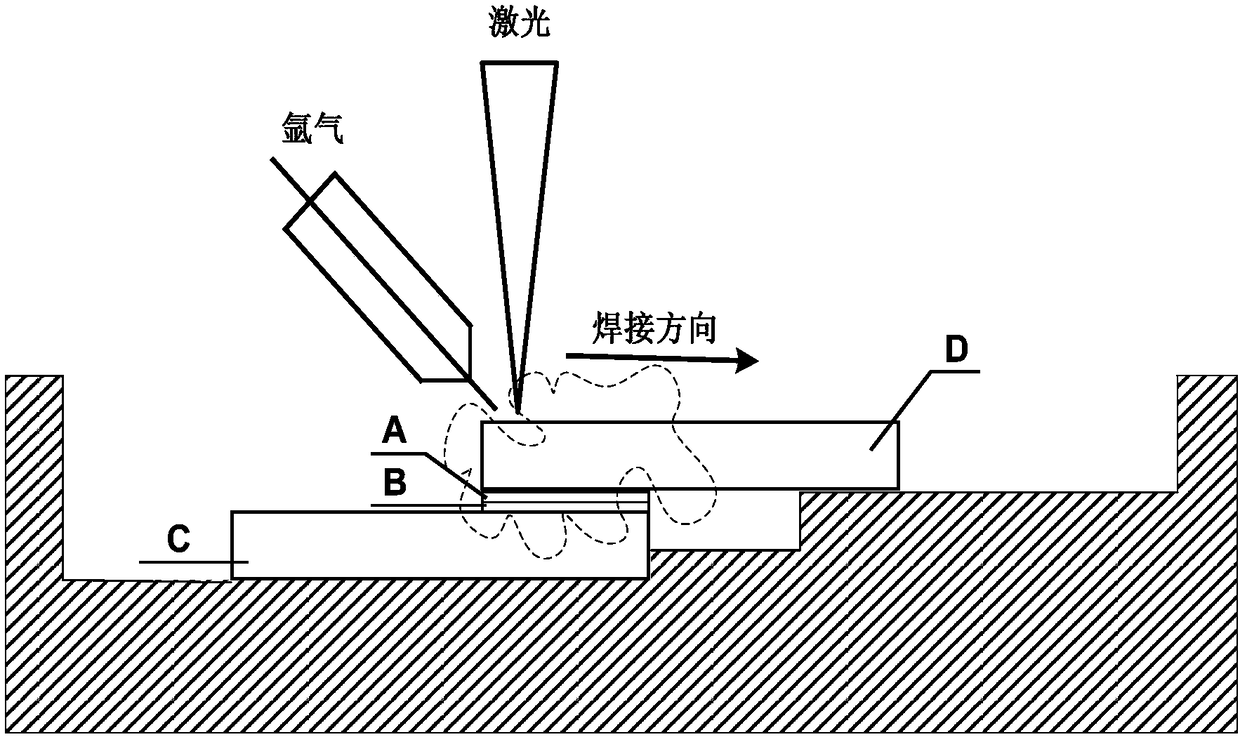

[0029] A method for laser brazing ceramics and metals with a composite high-entropy solder coating, the ceramic base material selected is ZrO 2 ceramics. The selected metal is Ti-6Al-4V alloy, and the specific composition is: Al6.0%, V3.5%, and the rest is Ti. The sample size is 2×10×40mm, and the coating is prepared by laser cladding. Pure Ni coating thickness is 20μm, NiCuCoFe 0.25 mn 1.75 The thickness of the high-entropy alloy coating is 40 μm.

[0030] After polishing the Ti-6Al-4V substrate to be welded with 400 mesh, 600 mesh, and 800 mesh water-resistant sandpaper, the substrate was polished with 0.5M diamond abrasive liquid, and the ZrO 2 Ceramics and Ti-6Al-4V alloy were placed in acetone and ultrasonically cleaned for 20 minutes to remove oil and impurities on the surface of the solder, and dried for later use.

[0031] After the processed substrate is assembled, it is fixed on a jig to ensure the stability of the brazing specimen.

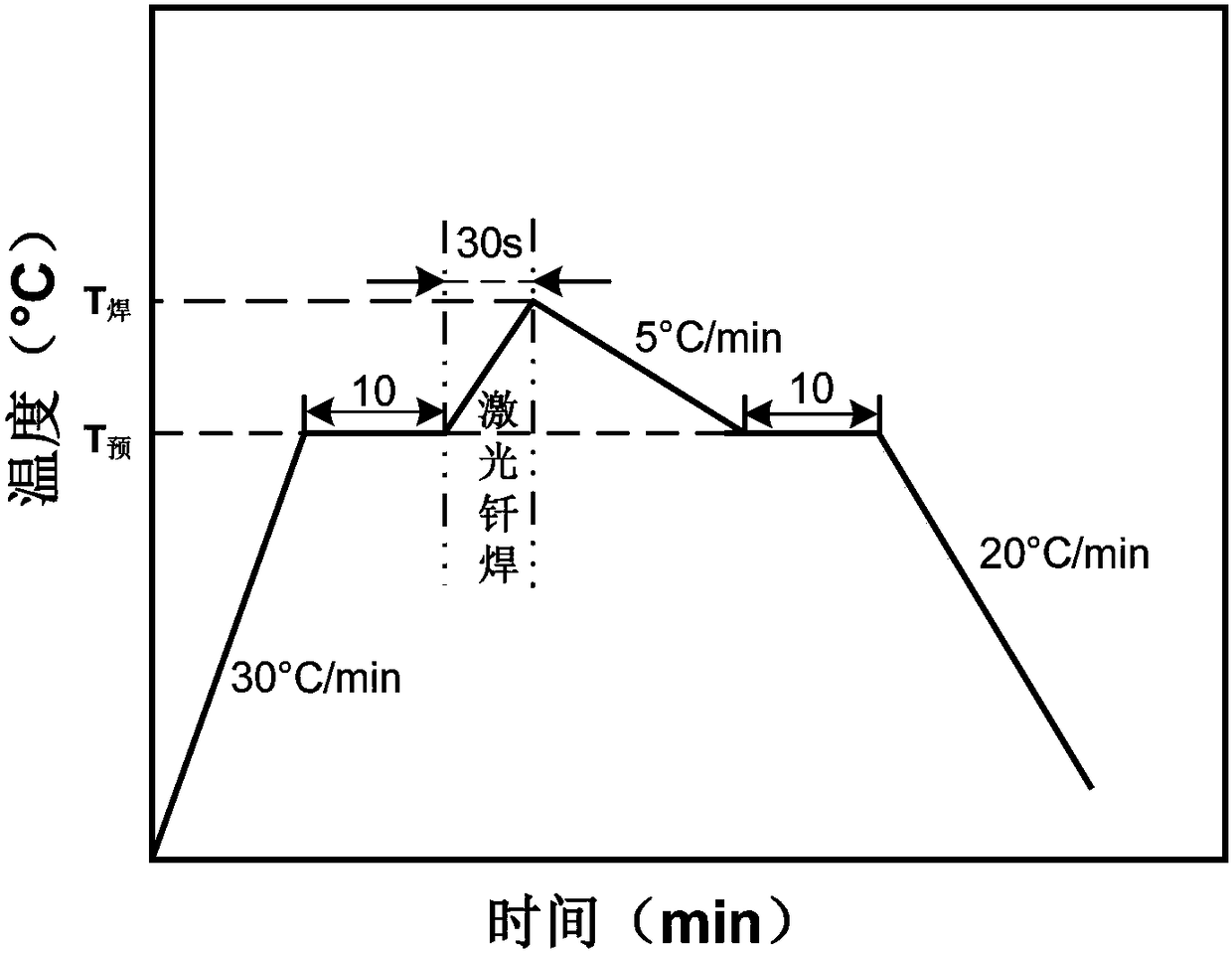

[0032] Before welding, pla...

Embodiment 2

[0035] A method for laser brazing ceramics and metals with a composite high-entropy solder coating, the ceramic base material selected is Si 3 N 4The ceramic sample scale is 2×10×40mm, the metal is GH4169 alloy, the sample size is 2×10×40mm, the coating is prepared by supersonic spraying, the thickness of the pure Ni coating is 20 μm, and the thickness of the high-entropy alloy coating is 40 μm .

[0036] After the GH4169 alloy substrate to be welded was polished with 400 mesh, 600 mesh, and 800 mesh water-resistant sandpaper, the substrate was polished with 0.5M diamond abrasive liquid, and the ZrO 2 The ceramics and Ti-6Al-4V alloy were cleaned in acetone for 20 minutes to remove oil and impurities on the surface of the solder, and dried for use.

[0037] After the processed substrate is assembled, it is fixed on a jig to ensure the stability of the brazing specimen.

[0038] Before welding, place the weldment in a high-temperature resistance furnace to preheat at 30°C / mi...

Embodiment 3

[0041] A method for laser brazing ceramics and metals with a composite high-entropy brazing material coating. The ceramic base material selected is SiC ceramics. The sample size is 2×10×40mm, and the metal is Ti-6Al-4V alloy. .0%, V3.5%, and the rest is Ti. The sample size is 2×10×40mm, and the coating is prepared by laser cladding. The thickness of the pure Ni coating is 20 μm, NiCuCoFe 0.25 mn 1.75 The thickness of the high-entropy alloy coating is 40 μm.

[0042] After grinding the Ti-6Al-4V alloy to be welded with 400 mesh, 600 mesh, and 800 mesh water-resistant sandpaper, the substrate was polished with 0.5M diamond abrasive liquid, and the ceramic with composite coating and Ti-6Al-4V The alloy is placed in acetone and ultrasonically cleaned for 20 minutes to remove oil and impurities on the surface of the solder, and dried for use.

[0043] After the processed substrate is assembled, it is fixed on a jig to ensure the stability of the brazing specimen.

[0044] Befor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Joint shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com