Current-assisted laser brazing method or laser fusion brazing method

A brazing method and laser melting technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of low energy utilization rate, uneven interface reaction space, poor wetting and spreading ability, etc., and achieve improved surface forming quality, promotion of wetting and spreading, promotion of homogenization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

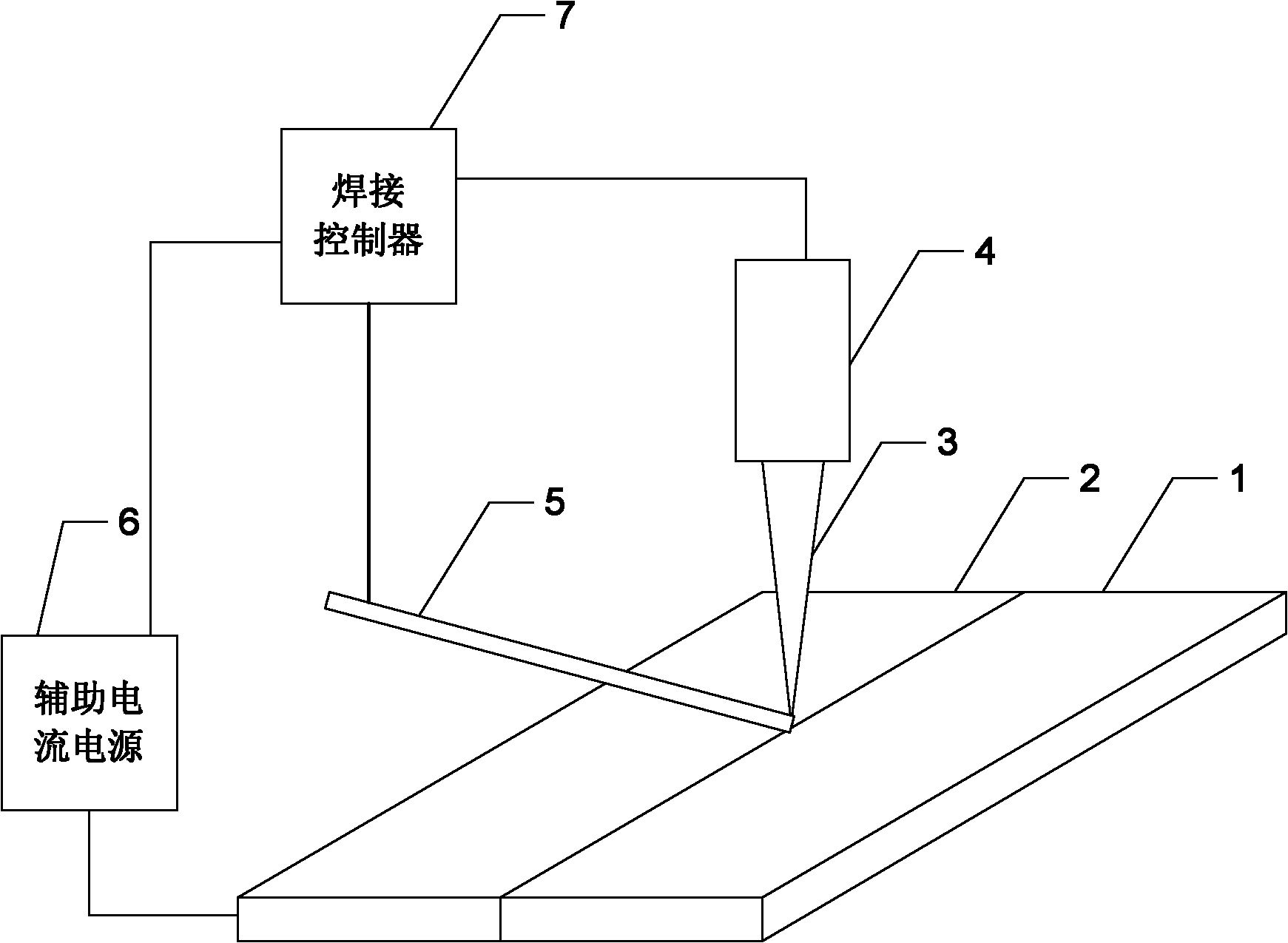

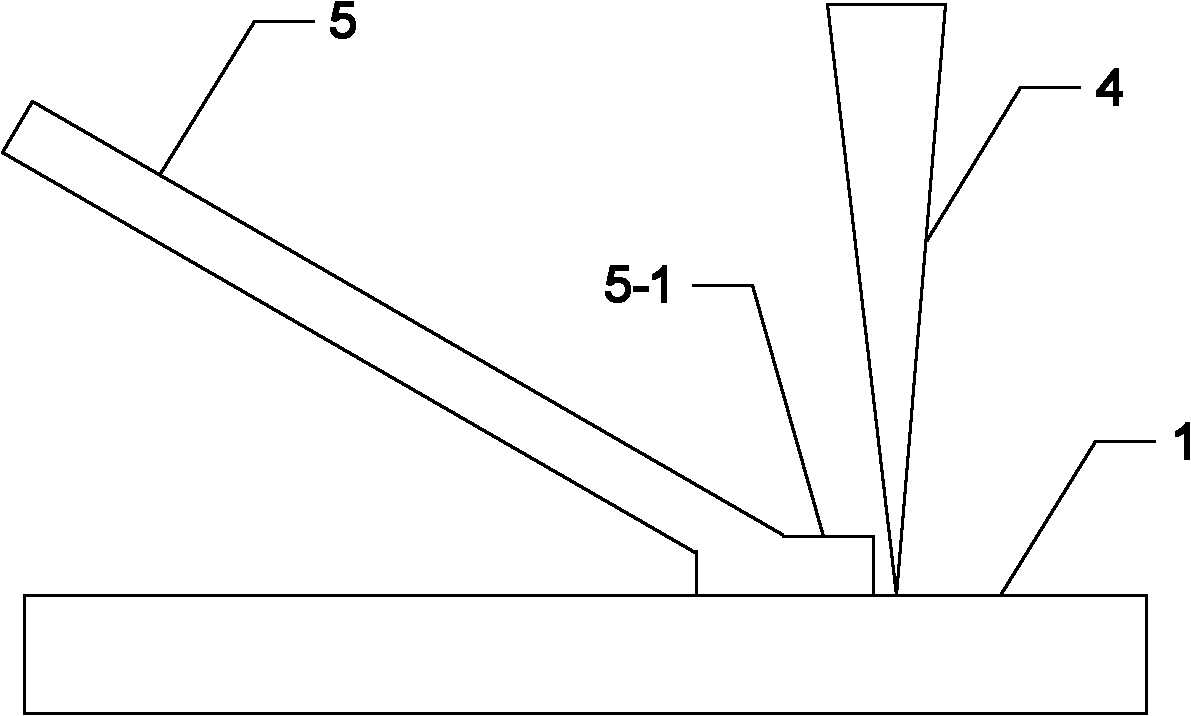

[0022] Specific implementation mode one: the following combination figure 1 with figure 2 Describe this embodiment, the current-assisted laser brazing method or laser fusion brazing method of this embodiment: during the welding process of the laser brazing method or laser fusion brazing, two base materials are connected to one power output end of the auxiliary current power supply, The other power output end of the auxiliary power supply is connected to the welding wire or the non-melting electrode through the welding controller. electrode.

[0023] The specific steps of the method described in this embodiment are:

[0024] Step 1. Pretreatment of the two base metals to be welded;

[0025] Step 2, fixing the two base materials to be welded on the workbench, and connecting the two base materials to an auxiliary current power supply;

[0026] Step 3, placing the welding wire or the non-melting electrode in front or behind the laser beam along the welding direction;

[0027...

specific Embodiment approach 2

[0042] Specific implementation mode two: the following combination image 3 with Figure 4 Describe this embodiment, the difference between this embodiment and Embodiment 1 is that the welding process parameters in step 4: the laser power is 1.4kW, the shielding gas flow rate is 20L / min, the welding auxiliary current is 100A, and the welding speed is 0.5m / min, the auxiliary current power supply adopts pulse power supply, and the welding auxiliary current pulse time t and pulse interval time t 0 The ratio of t / t 0 is 3, and the others are the same as those in Embodiment 1.

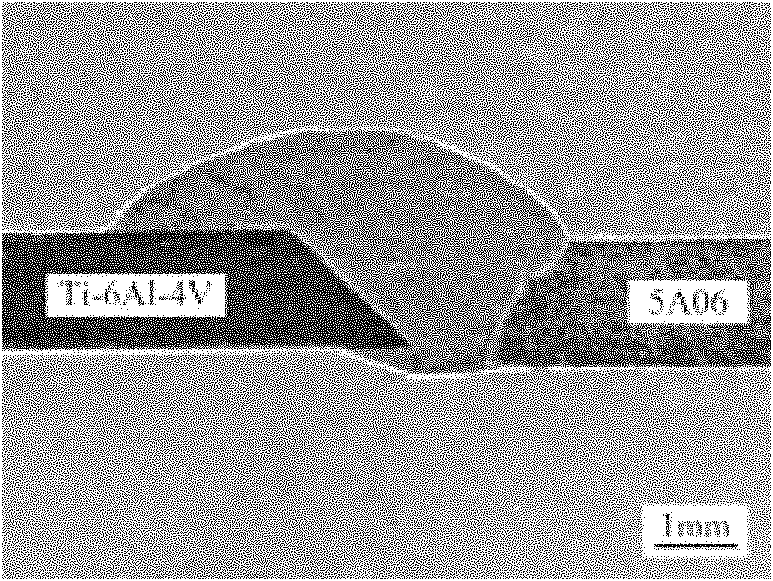

[0043] This embodiment provides a specific example to illustrate the effect of the method of the present invention, image 3 It is the morphology of Ti / Al dissimilar alloy laser fusion brazing joint without auxiliary current. Figure 4 It is the morphology of Ti / Al dissimilar alloy laser fusion brazing joint with auxiliary current. image 3 The process parameters are: laser power P=1800W, welding speed V...

specific Embodiment approach 3

[0044] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the welding process parameters in step 4: the laser power range is 100W-6kW, the shielding gas flow rate is 5L / min-20L / min, and the welding auxiliary current The range is 10A~10kA, the welding speed is 0.5m / min~2m / min, the auxiliary current power supply adopts pulse power supply, and the welding auxiliary current pulse time t and pulse interval time t 0 The ratio of t / t 0 1.5 to 3, and the others are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com