Welding head for laser narrow-gap welding

A narrow gap, welding head technology, applied in the field of laser narrow gap welding head, can solve the problem of no welding head and so on

Active Publication Date: 2018-02-23

BEIJING UNIV OF TECH

View PDF8 Cites 8 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In laser narrow gap welding, the welding head is the most critical factor affecting the welding process and welding quality except the laser, but there is still no welding head dedicated to laser narrow gap welding.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 2

[0026] The difference from Embodiment 1 is that the focus position, welding wire position and shielding gas nozzle position are automatically controlled by setting a motor system on the side of the moving mechanism.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

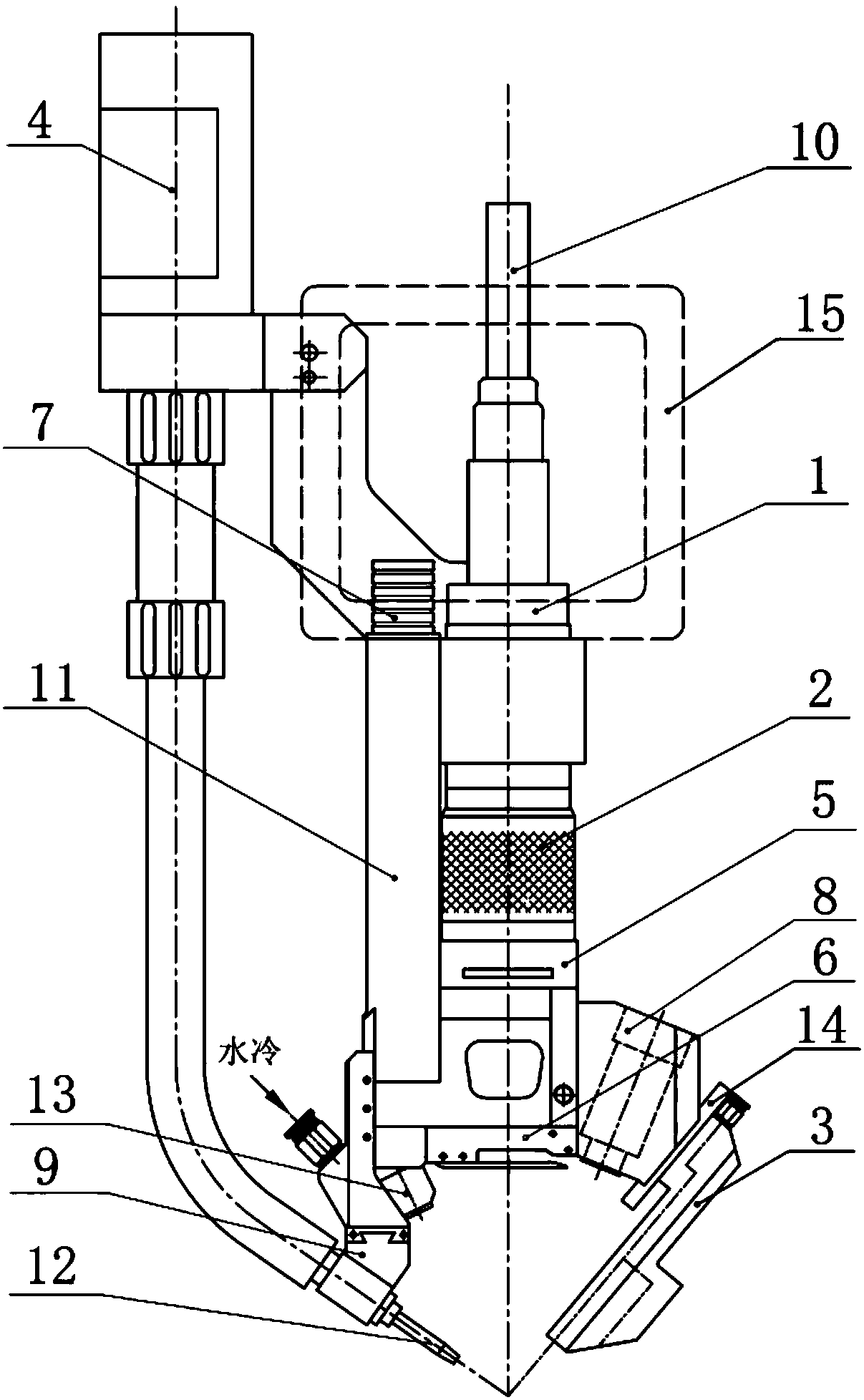

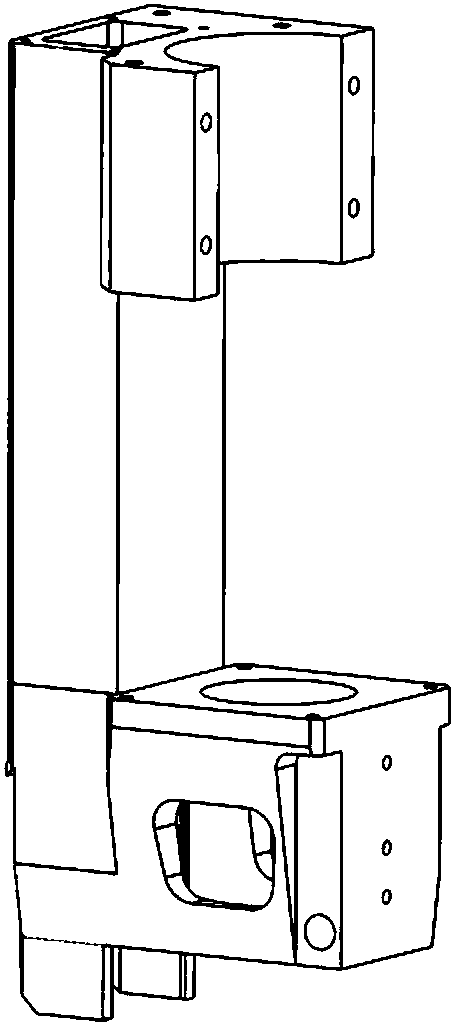

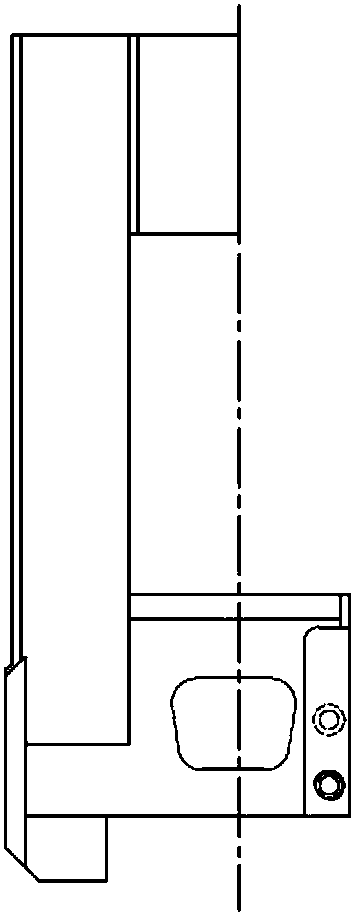

The invention relates to a welding head for laser narrow-gap welding. The welding head can be used for laser narrow-gap multi-layer welding on thick plates and can also be used for laser wire fillingwelding, laser soldering and the like. The structure of the welding head mainly comprises the main parts such as a welding head base body, a laser transmission and focusing module, a welding wire conveying module, a gas protection module, a transverse gas proof curtain and a charge coupled device observation module. During welding, movement mechanisms, such as a mechanical arm, are responsible formoving according to preset routes, the position of optical focal point and the height of the wire feeding drop point can be manually or automatically adjusted only according to the gap depth and width in each layer of welding bead, and the positions of other parts including the welding head base body, a gas protection nozzle and the charge coupled device observation module are not changed; only when the accumulated height of weld joints exceeds a certain value, the heights of the movement mechanisms are required to change, and welding can be completed by repeating the above processes. The welding head adopts a modular design, is compact in structure, and has the characteristics of being high in adaptability, high in welding efficiency and convenient to operate and maintain.

Description

technical field [0001] The invention relates to a laser narrow gap welding head, which belongs to the field of laser processing. Background technique [0002] A large number of thick-walled structures are used in nuclear power, petrochemical, shipbuilding, marine engineering and other industrial fields. Welding is one of the most critical processes in the manufacturing process of these structures, and welding is also a key link that determines production efficiency. For the welding of thick plates with large precision structures, narrow gap welding is usually selected due to strict requirements on weld quality, weld shape, welding deformation, etc. At present, the main methods of narrow gap welding are narrow gap TIG and narrow gap MIG. However, these two narrow-gap arc welding have obvious shortcomings such as large heat input, serious stress deformation of the welding structure, large metal filling due to wide gap, and low welding efficiency. With the rapid development of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K26/21B23K26/03B23K26/14B23K26/142B23K26/70

CPCB23K26/032B23K26/14B23K26/142B23K26/21B23K26/702

Inventor 杨武雄李飞武强肖荣诗

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com