Carbide blade laser brazing method

A technology of cemented carbide blades and brazing methods, applied in welding media, metal processing, welding equipment, etc., can solve the problems of weld tensile strength drop, cemented carbide cracking, cemented carbide cracking, etc., and achieve high precision Flexible positioning, reduced cracking probability, smooth and smooth weld seam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

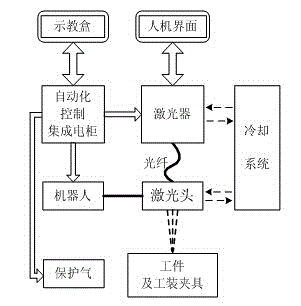

[0023] The laser brazing system is built by using ZKSX3004 fiber-coupled output all-solid-state laser (supporting optical fiber and laser head) of Jiangsu Zhongke Sixiang Laser Technology Co., Ltd. and Japanese FANUC robot. The ZKSX3004 fiber-coupled output all-solid-state laser is side-pumped by a semiconductor diode array, with a rated power of 3kW. It is the first time in China to realize a 400μm fiber-coupled continuous output, and the coupling efficiency is as high as 96.7%. The laser adopts a PLC control system with high-precision laser power. The closed-loop control and automatic compensation function make the laser output power stability within 2%; the man-machine interface is friendly, the integration interface is simple, and the system integration with robots and machine tools can be easily realized.

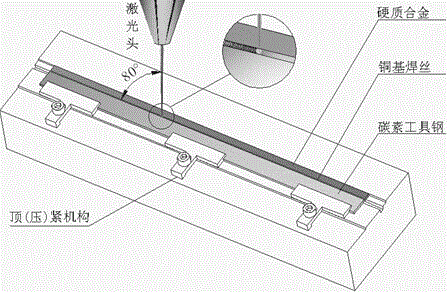

[0024] Carbide with a tungsten content of 99% and T8MnA were selected for laser brazing, H80 copper wire was used as the solder, the shielding gas was Ar gas, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com