Box-building type optical fiber splicing unit capable of being repeatedly opened and used

An optical fiber splicer and optical fiber technology, applied in the coupling of optical waveguides, etc., can solve the problems of difficult connection, long operation time, time-consuming and laborious, etc., and achieve the effect of improving connection quality, reducing fiber penetration, and reducing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below in conjunction with the accompanying drawings.

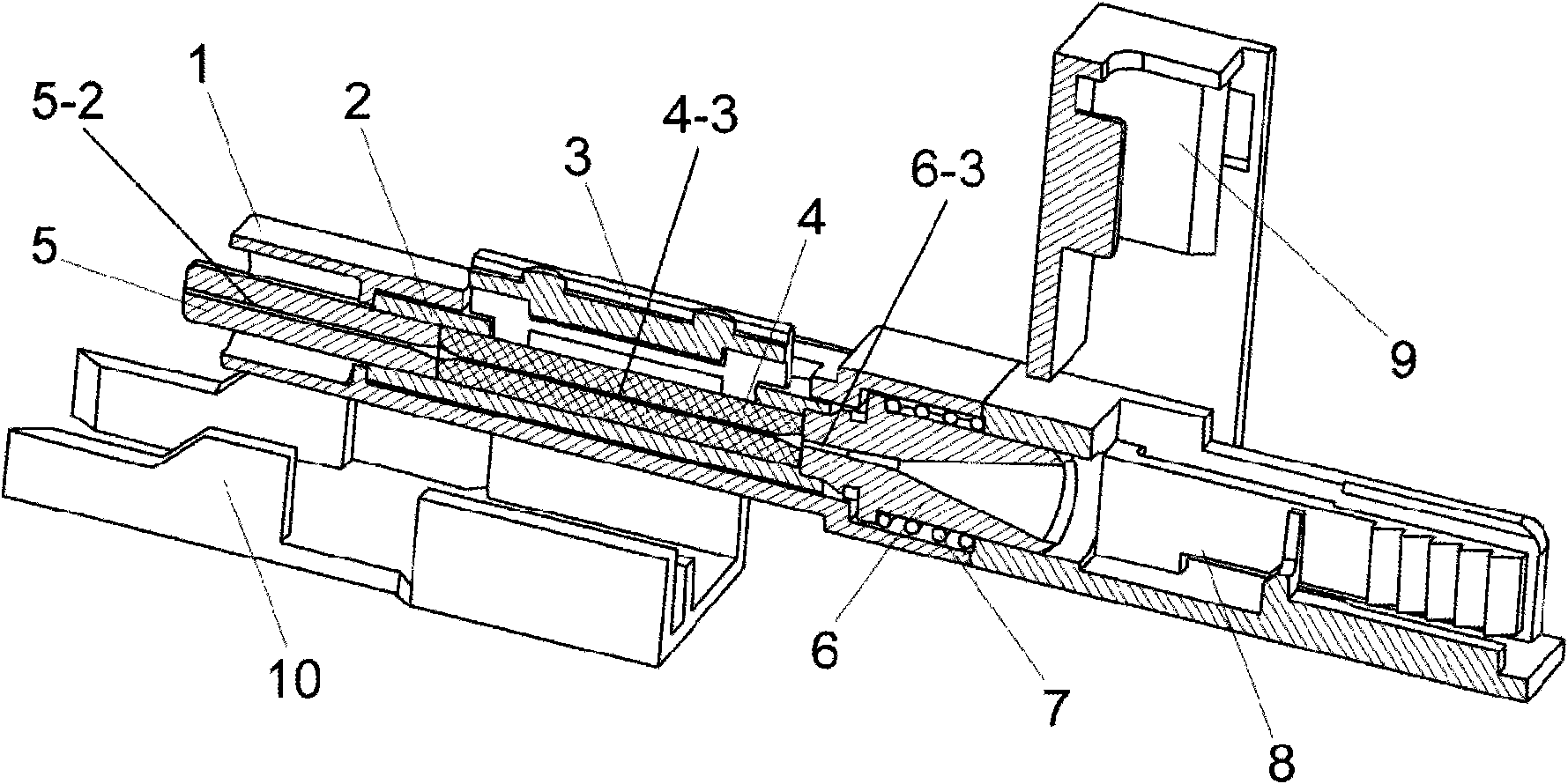

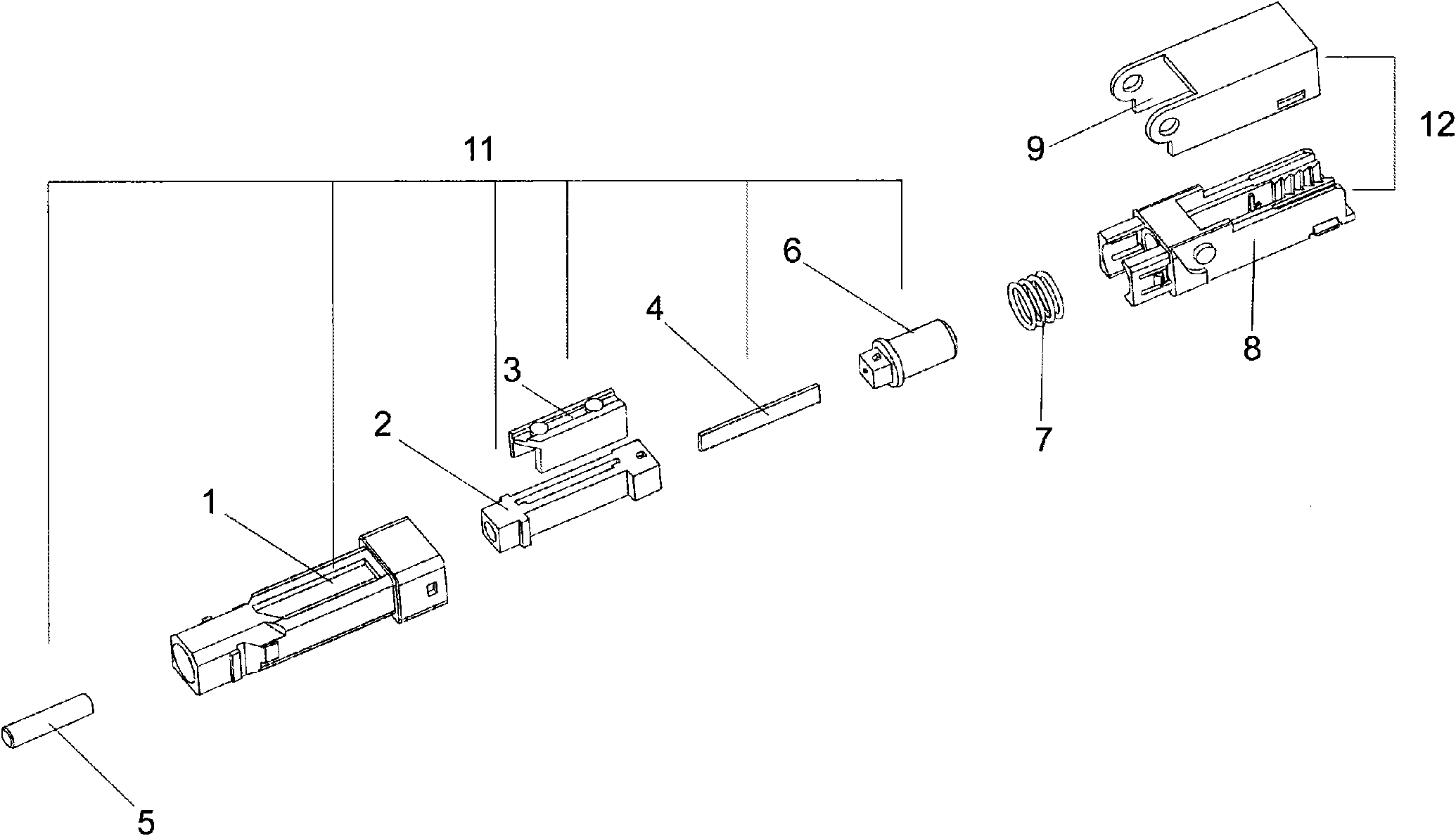

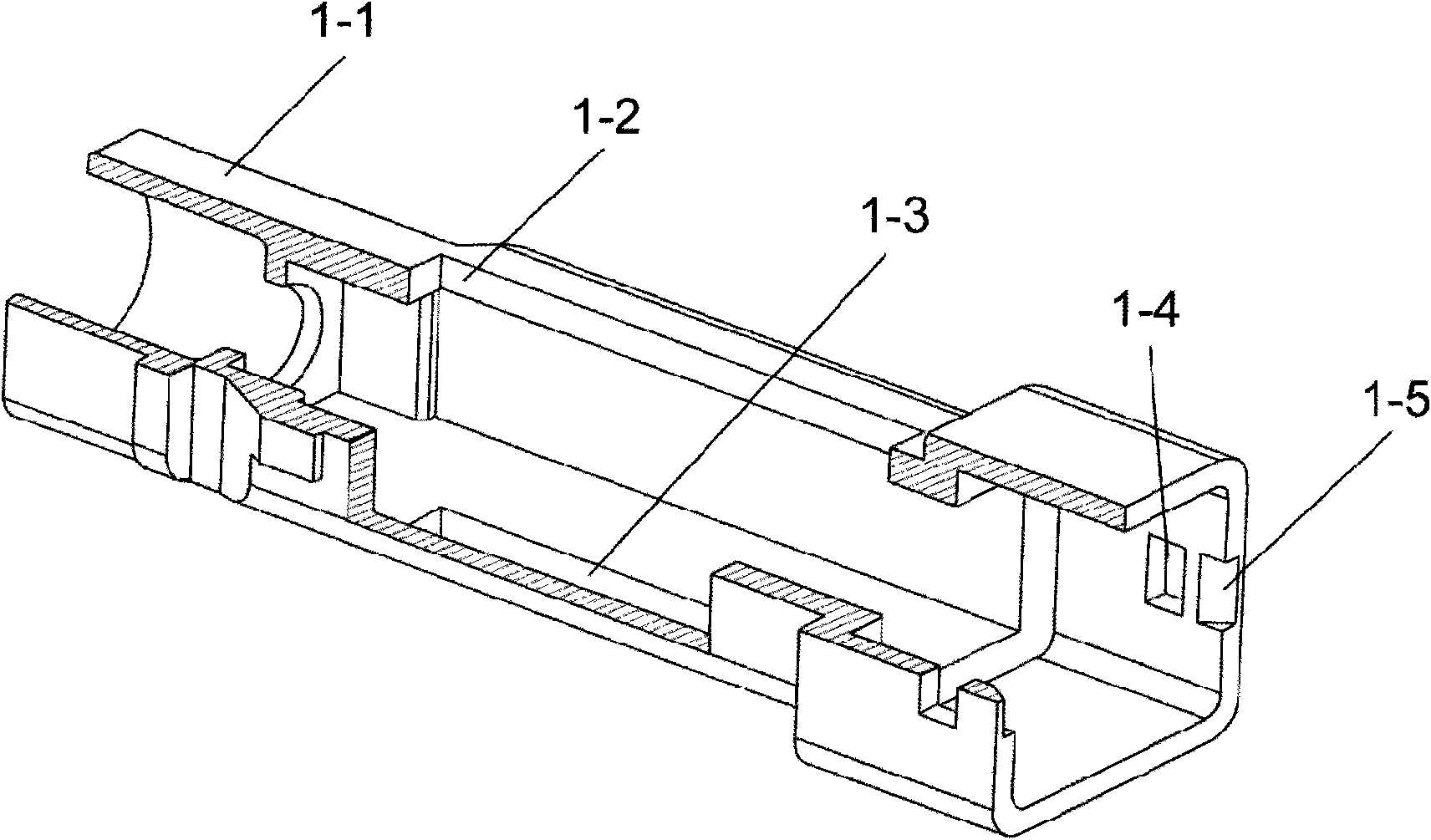

[0045] like figure 1 , 2 , 4, 5, 6, 9, 10, 12, including the front box assembly 11, the rear box assembly 12, the spring 7 and the opening cover 10, the front box assembly 11 includes Shell 1, front box body 2, building cover 3, V-groove metal block 4, ferrule 5 and guide block 6; a floating block 2-2 is arranged in the middle of the front box body 2, and the floating The two sides of the block 2-2 are 2-1 embedding grooves and building grooves 2-5 respectively; the V-shaped groove metal block 4 is embedded in the embedding groove 2-1, and a V-shaped groove 4 is arranged on the opposite surface of the floating block. -1, and form an optical fiber through hole 4-3 with it; the said building cover 3 is attached to the front box body 2, and the brickwork 3-3 on one side of the building cover 3 is pressed into the building groove of the front box body 2 In 2-5, the sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com