Lead-connecting device

A technology of wire connection and guide device, applied in the direction of connection, circuit/collector parts, electrical components, etc., can solve the problems of affecting wire process quality, unstable labor control, high labor intensity of workers, and achieve work efficiency and wire connection. The effect of high quality, improved labor efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

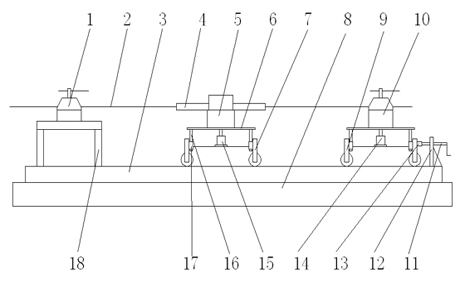

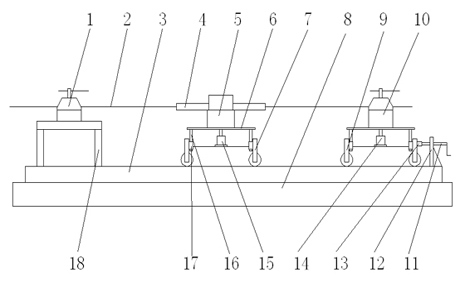

[0010] Such as figure 1 As shown, the wire connection device includes a workbench 8, a guide rail 3 fixed on the workbench, a fixed frame 18 installed at the left end of the guide rail, a wire clamping trolley 9 installed at the right end of the guide rail, and a wire clamping trolley installed between the fixed frame and the conductor clamping trolley. Between the trolley 7 that can move along the guide rail, the hydraulic press pliers head 5 is installed on the fixed plate 6 on the trolley, and a lifting device and a guiding device for moving the fixed plate up and down are installed between the fixed plate and the trolley. The above-mentioned lifting device is a hydraulic cylinder. 15. The above-mentioned lifting device is composed of a guide sleeve 17 and a guide column 16 matched with the guide sleeve. The guide sleeve is fixed on the trolley, and the guide column is fixed on the fixed plate. Fixedly installed on the fixed frame 17 and the wire clamping dolly 9 of the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com