Preparation method of pure rhenium product

A technology of pure rhenium products, which is applied in the field of preparation of pure rhenium products, can solve problems such as difficulties in production and processing, and achieve the effects of large size, novel technical ideas, and simple process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

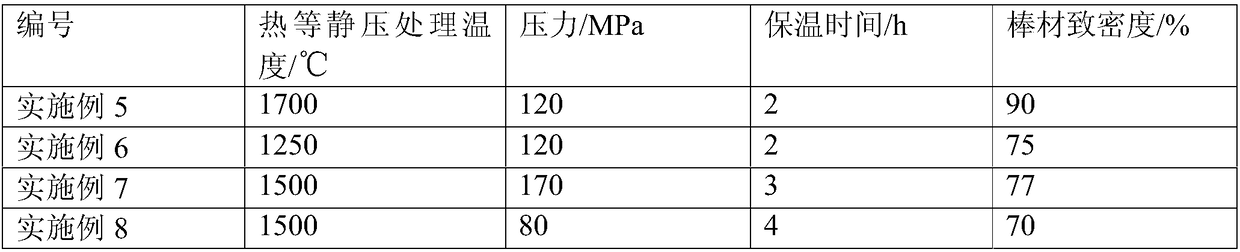

Examples

Embodiment 1

[0034] 1) rhenium powder pretreatment: take 20Kg pure rhenium powder, add 4% paraffin wax (that is, the addition of paraffin wax is 4% of rhenium powder quality) by mass percentage as binding agent, and mix homogeneously, the rhenium powder of described The particle size is -325 mesh;

[0035] 2) Press molding: put the wax-mixed powder into a cylindrical mold, and carry out cold isostatic pressing molding, the pressing pressure is 200MPa, the holding time is 20s, and a green compact with a relative density of 62% is obtained;

[0036] 3) Dewaxing: use a dewaxing furnace to dewax the compact, the dewaxing temperature is 900°C, and the holding time is 4h;

[0037] 4) Pre-sintering: pre-sintering the blank obtained in step 3) under vacuum conditions, the pre-sintering temperature is 1200°C, the holding time is 2h, and the vacuum degree is 10 -2 Pa, to obtain pre-sintered compact;

[0038] 5) Covering: using titanium plate as the covering material to cover the pre-sintered bille...

Embodiment 2

[0045] 1) rhenium powder pretreatment: take 24Kg pure rhenium powder, add 5% paraffin (that is, the addition of paraffin wax is 5% of the quality of rhenium powder) by mass percentage as a binder, and mix uniformly, the rhenium powder The particle size is -250 mesh;

[0046] 2) Press molding: put the wax-mixed powder into a square mold, carry out cold isostatic press molding, the pressing pressure is 150MPa, and the holding time is 30s to obtain a compact with a relative density of 65%;

[0047] 3) Dewaxing: use a dewaxing furnace to dewax the compact, the dewaxing temperature is 1000°C, and the holding time is 3h;

[0048] 4) Pre-sintering: pre-sintering the blank obtained in step 3) under vacuum conditions, the pre-sintering temperature is 1300°C, the holding time is 3h, and the vacuum degree is 10 -2 Pa, to obtain pre-sintered compact;

[0049] 5) Covering: use molybdenum-rhenium plate as the covering material to cover the pre-sintered billet and vacuumize it;

[0050] 6...

Embodiment 3

[0055] 1) rhenium powder pretreatment: take 40Kg pure rhenium powder, add 2% paraffin wax (that is, the addition of paraffin wax is 2% of rhenium powder quality) by mass percentage as binder, and mix uniformly, the rhenium powder The particle size is -150 mesh;

[0056] 2) Press molding: put the wax-mixed powder into a square mold, carry out cold isostatic press molding, the pressing pressure is 240MPa, the holding time is 30s, and the green compact with a relative density of 68% is obtained;

[0057] 3) Dewaxing: use a dewaxing furnace to dewax the compact, with a dewaxing temperature of 730°C and a holding time of 4 hours;

[0058] 4) Pre-sintering: pre-sintering the blank obtained in step 3) under vacuum conditions, the pre-sintering temperature is 1100°C, the holding time is 5h, and the vacuum degree is 10 -2 Pa, to obtain pre-sintered compact;

[0059] 5) Covering: use molybdenum-rhenium plate as the covering material to cover the pre-sintered billet and vacuumize it; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com