Aluminum-plastic extrusion composite film of lithium ion battery and preparation method of composite film

A lithium-ion battery, extrusion compounding technology, applied in battery pack parts, chemical instruments and methods, circuits, etc. Corrosion resistance, poor insulation and other problems, to achieve the effect of enhancing electrolyte resistance, elongation at break, and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

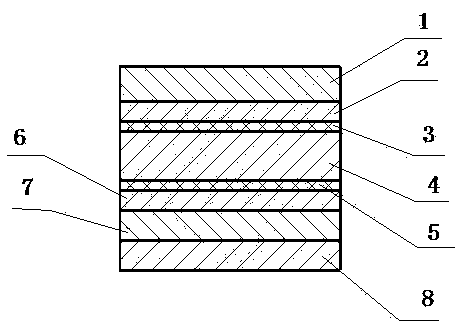

[0017] Embodiment 1, with reference to figure 1 , an aluminum-plastic extrusion composite film for a lithium-ion battery, which consists of a protective layer 1, a first extrusion layer 2, a first coating 3, an aluminum foil layer 4, a second coating 5, and a second extrusion coating from outside to inside. Layer 6, homopolymer layer 7 and heat-sealing layer 8; the first coating 3 and the second coating 5 are sprayed on the upper and lower sides of the aluminum foil layer 4 respectively, and the protective layer 1 and the first coating 3 pass through the extruded layer 2 Bonding, between the second coating 5 and the heat-sealing layer 8, co-extruded and bonded by the extrusion layer 6 and the homopolymer layer 7;

[0018] The protective layer 1 is a polyethylene terephthalate layer or a biaxially stretched nylon layer;

[0019] The first coating 3 and the second coating 5 contain ammonium molybdate and sodium silicate, and also contain a mixed aqueous solution composed of any...

Embodiment 2

[0023] Embodiment 2, with reference to figure 1 , an aluminum-plastic extrusion composite film for a lithium-ion battery, which consists of a protective layer 1, a first extrusion layer 2, a first coating 3, an aluminum foil layer 4, a second coating 5, and a second extrusion coating from outside to inside. Layer 6, homopolymer layer 7 and heat-sealing layer 8; the first coating 3 and the second coating 5 are sprayed on the upper and lower sides of the aluminum foil layer 4 respectively, and the protective layer 1 and the first coating 3 pass through the extruded layer 2 Bonding, between the second coating 5 and the heat-sealing layer 8, co-extruded and bonded by the extrusion layer 6 and the homopolymer layer 7;

[0024] The protective layer 1 is a polyethylene terephthalate layer or a biaxially stretched nylon layer;

[0025] The first coating 3 and the second coating 5 contain ammonium molybdate and sodium silicate, and also contain a mixed aqueous solution of any composit...

Embodiment 3

[0029] Embodiment 3, with reference to figure 1 , an aluminum-plastic extrusion composite film for a lithium-ion battery, which consists of a protective layer 1, a first extrusion layer 2, a first coating 3, an aluminum foil layer 4, a second coating 5, and a second extrusion coating from outside to inside. Layer 6, homopolymer layer 7 and heat-sealing layer 8; the first coating 3 and the second coating 5 are sprayed on the upper and lower sides of the aluminum foil layer 4 respectively, and the protective layer 1 and the first coating 3 pass through the extruded layer 2 Bonding, between the second coating 5 and the heat-sealing layer 8, co-extruded and bonded by the extrusion layer 6 and the homopolymer layer 7;

[0030] The protective layer 1 is a polyethylene terephthalate layer or a biaxially stretched nylon layer;

[0031] The first coating 3 and the second coating 5 contain ammonium molybdate and sodium silicate, and also contain a mixed aqueous solution composed of flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com