Battery casing and battery casing safety valve forming method

A technology of battery casing and safety valve, which is applied in the directions of large-sized batteries/battery packs, small-sized batteries/battery packs, battery pack components, etc., can solve the difficulty of ensuring the accuracy of groove shape, large forming force, Problems such as low elastic coefficient, to achieve the effect of easy stamping and reliable cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, in this specification and drawing, the same code|symbol is attached|subjected to the component which has substantially the same functional structure, and repeated description is abbreviate|omitted.

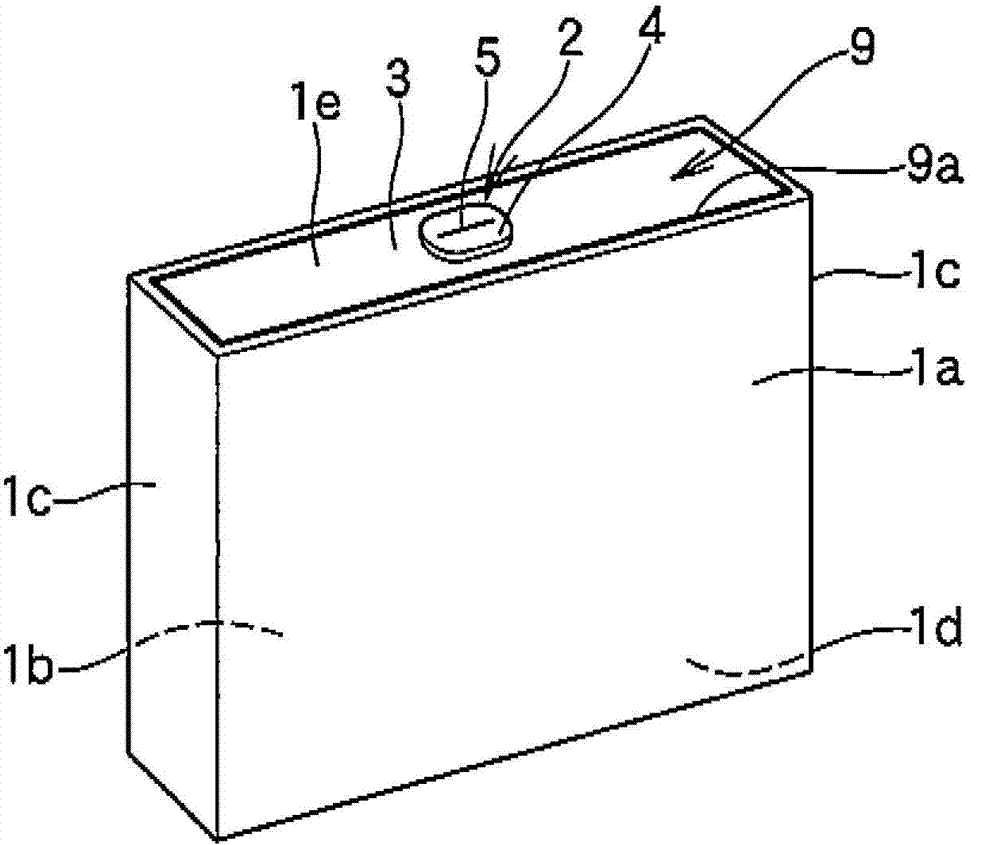

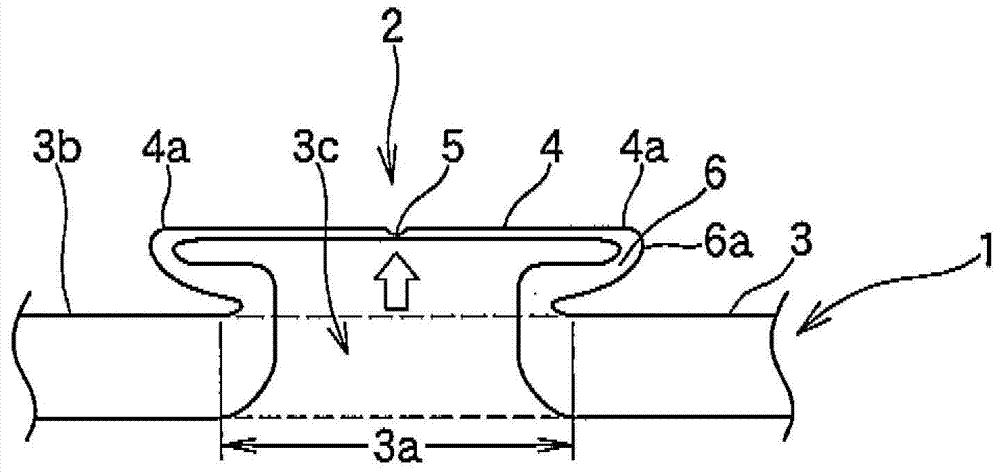

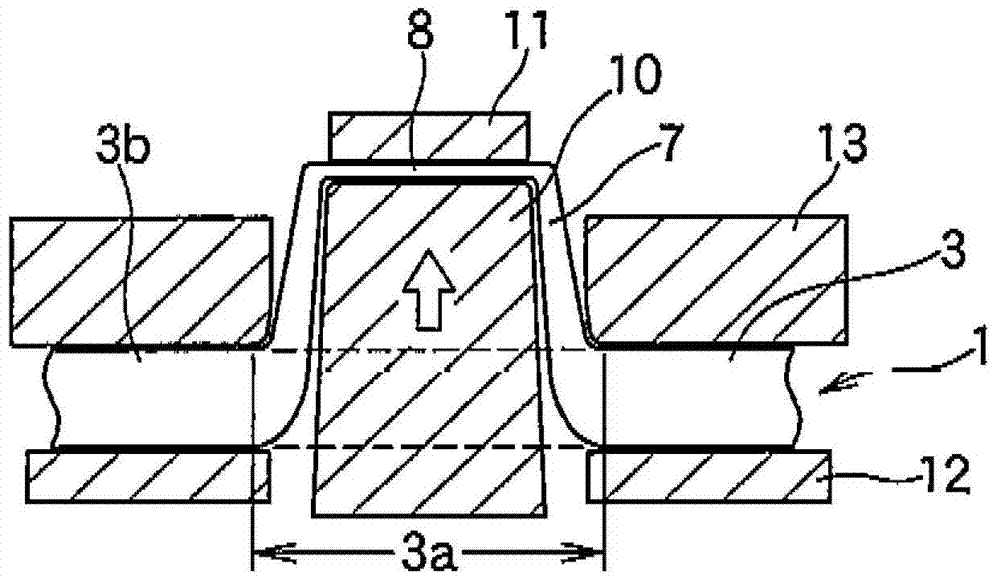

[0056] exist figure 1 The whole figure of the case of the Li ion battery of this invention is shown by the perspective view in . In addition, in figure 2 Indicated by the main part of the cross-sectional view figure 1 Implementation of the safety valve. The above-mentioned Li-ion battery case of the present invention becomes the on-board power source for the above-mentioned mobile phone, notebook computer, or automobile.

[0057] The basic structure of the battery case:

[0058] figure 1 , 2 The Li-ion battery case 1 of the present invention is formed into a square battery case from an aluminum alloy thin plate (cold-rolled plate) m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com