Coil and magnetic powder integrated inductor and manufacturing method thereof

A molding and magnetic powder technology, applied in coil manufacturing, inductance/transformer/magnet manufacturing, inductors, etc., can solve problems such as easy damage to the insulation layer, particle fragmentation, and device heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

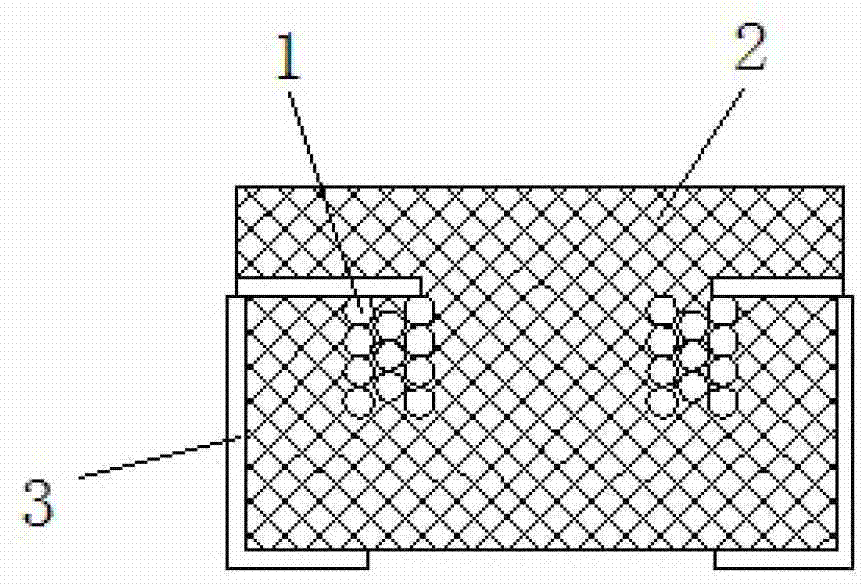

Embodiment 1

[0023] Fe with an average particle diameter of 23 μm and 4.6 μm 89 Si 6.5 Cr 2.5 B 2 The iron-based amorphous metal magnetic powder is mixed in three ratios of 100 to 0, 75 to 25 and 50 to 50, respectively. Add E5284 single-component high-temperature curing high-temperature-resistant epoxy resin (produced by Beijing Hangtongzhou Technology Co., Ltd.) with 4.8% of the weight of the magnetic powder to each magnetic powder, and mix. Mix magnetic powder and resin into a clay-like dough. Preheat the clay-like dough to 100°C and fill it into a ring mold. Compressed with a pressure of 1 kgf per square centimeter. The sample size is 17mm in outer diameter, 7.0mm in inner diameter, and 5.0mm in height. Keep the highest pressure state, heat the mold to 140-160°C, keep warm for 8-15 minutes, and cure the resin. Use the B-H analyzer to measure the performance of the magnetic material under the condition of 300Khz-40mT, and the test results are shown in Table 1.

[0024] Table 1 Eff...

Embodiment 2

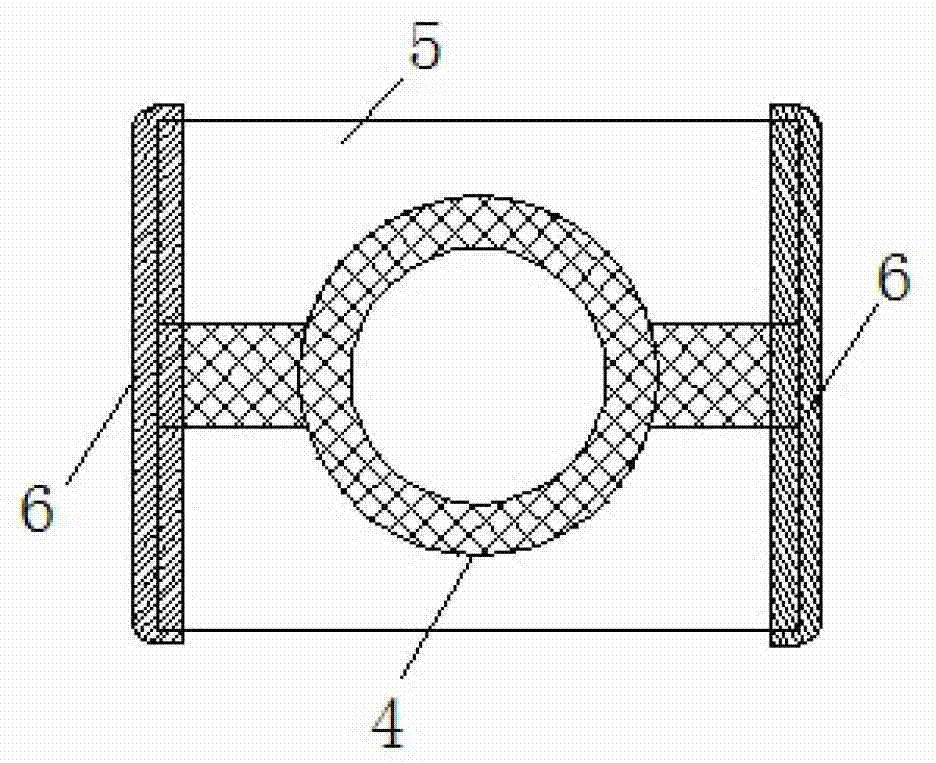

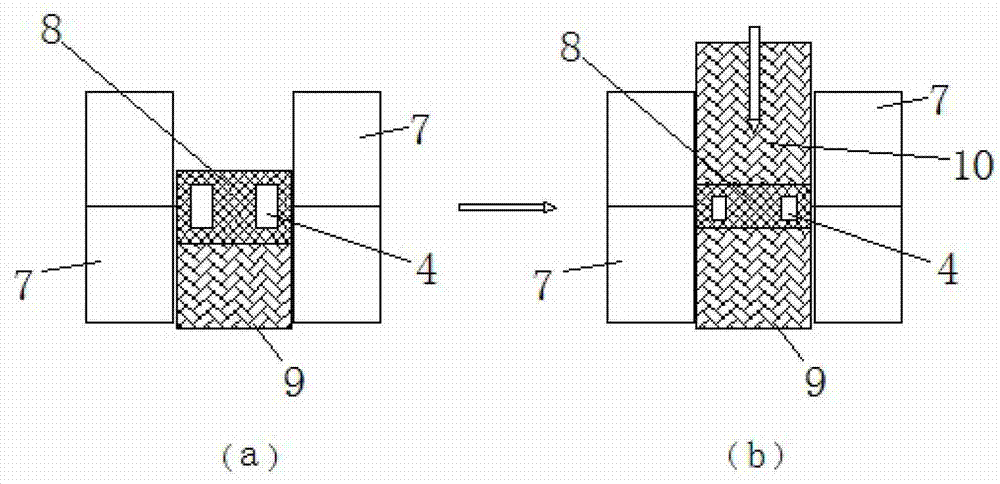

[0036] The method of the present invention is used to make an inductor with an external dimension of 6.7*7.4*3.0mm, the inductance is 1.0 μH, and the magnetic powder used is Fe 88.5 Si 6.5 Cr 2.5 B 2.5The amorphous alloy magnetic powder has an average particle diameter of 23μm and 5μm, and the weight ratio is 75:25. The amount of epoxy resin added is 4.8% of the weight of the magnetic powder. The enameled wire of the coil used is flat, with a width of 1.8mm and a thickness of 0.25mm. The specification is 220-Ⅱ (produced by Jiangxi Jiateng Wire Co., Ltd.). Heat the forming mold and lower punch to 100°C, heat the magnetic powder mass to 100°C, fill the coil and magnetic powder mass into the mold, pressurize, the pressure is 120±1kgf, heat up to 150±2°C, pressurize and keep warm 9-10 minutes, take out the finished product. Polish the end face with Φ500 diamond fine sand, and then vacuum sputter platinum to form the lead-out electrode.

[0037] Inductors with the same dimensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| inductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com