1xxx/5xxx aluminum alloy composite and preparing method thereof

A composite material and aluminum alloy technology, which is applied in the field of preparation of 1xxx/5xxx aluminum alloy composite materials, can solve the problems of reducing the quality of welds, reducing the welding performance of fenders and other covering parts, etc., and achieves good structural strength and corrosion resistance. Performance, welding performance improvement, easy stamping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

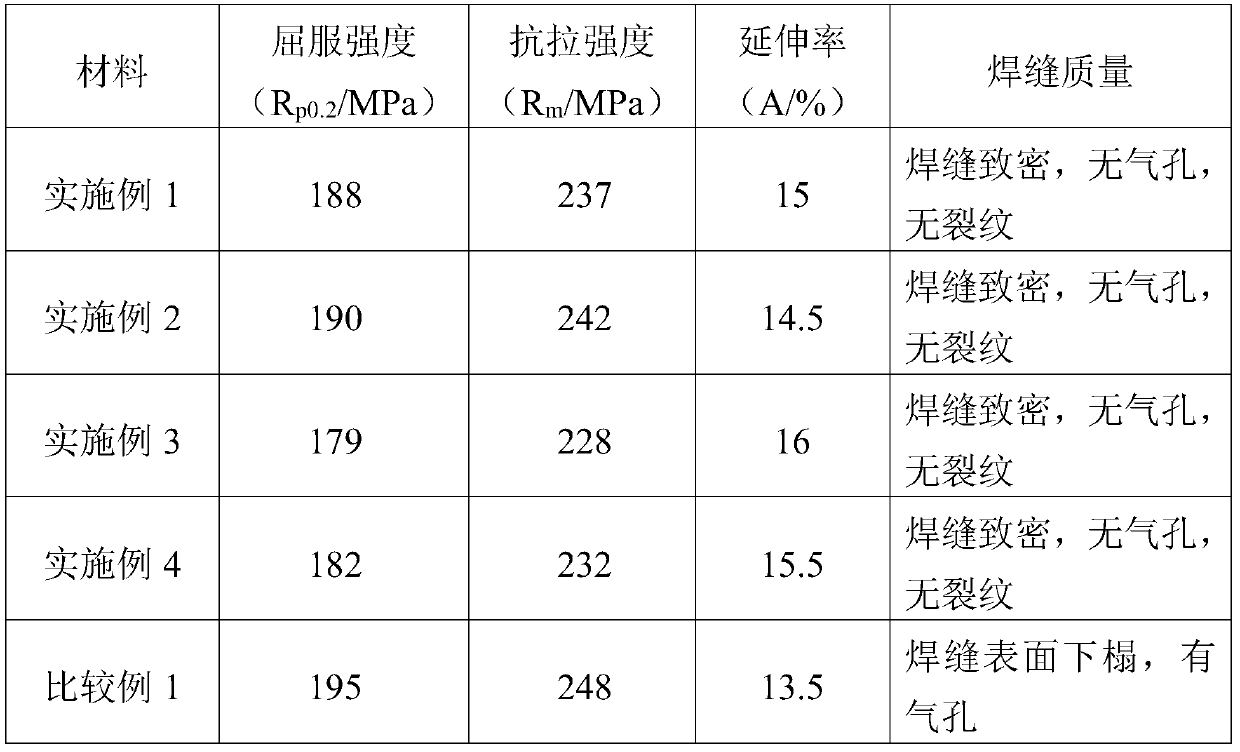

Examples

Embodiment 1

[0021] A 1xxx / 5xxx aluminum alloy composite material, including a core alloy layer and a cladding alloy layer, the alloy composition of the core layer is composed of the following components in terms of mass percentage: Si 0.06%, Fe 0.15%, Cu 0.02%, Mn 0.08%, Mg 2.4%, Cr 0.25%, Zn 0.04%, the balance is Al and unavoidable elements; the mass percentage of each element in the cladding layer alloy: Si 0.04%, Fe 0.13%, Cu 0.006%, Mn 0.03%, Mg 0.008%, Zn 0.02%, V 0.03%, Ti 0.03%, the balance is Al and unavoidable elements; the preparation method of the 1xxx / 5xxx aluminum alloy composite material, the operation steps are as follows:

[0022] (1) Preparation of core layer alloy and cladding layer alloy plates: batching is carried out according to the designed core layer and cladding layer alloy composition, and after melting, degassing, filtering and casting, core layer alloy ingots and cladding layer alloy ingots with a thickness of 520 mm and The clad layer alloy ingot is cast, and ...

Embodiment 2

[0029] A 1xxx / 5xxx aluminum alloy composite material, including a core alloy layer and a cladding layer alloy layer, the alloy composition of the core layer is composed of the following components in terms of mass percentage: Si 0.25%, Fe 0.12%, Cu 0.10%, Mn 0.05%, Mg 2.2%, Cr 0.15%, Zn 0.10%, the balance is Al and unavoidable elements; the mass percentage of each element in the cladding layer alloy: Si 0.09%, Fe 0.40%, Cu 0.05%, Mn 0.02%, Mg 0.006%, Zn 0.05%, V 0.05%, Ti0.01%, the balance is Al and unavoidable elements; the preparation method of the 1xxx / 5xxx aluminum alloy composite material, the operation steps are as follows:

[0030] (1) Preparation of core layer alloy and cladding layer alloy plates: batching is carried out according to the designed core layer and cladding layer alloy composition, and after melting, degassing, filtering and casting, core layer alloy ingots and cladding layer alloy ingots with a thickness of 520 mm and The cladding layer alloy ingot is ca...

Embodiment 3

[0037]A 1xxx / 5xxx aluminum alloy composite material, including a core alloy layer and a cladding alloy layer, the alloy composition of the core layer is composed of the following components in terms of mass percentage: Si 0.10%, Fe 0.08%, Cu 0.03%, Mn 0.03%, Mg 2.8%, Cr 0.35%, Zn 0.02%, the balance is Al and unavoidable elements; the mass percentage of each element in the cladding layer alloy: Si 0.07%, Fe 0.08%, Cu 0.008%, Mn 0.03%, Mg 0.01%, Zn 0.02%, V 0.02%, Ti0.02%, the balance is Al and unavoidable elements; the preparation method of the 1xxx / 5xxx aluminum alloy composite material, the operation steps are as follows:

[0038] (1) Preparation of core layer alloy and cladding layer alloy plates: batching is carried out according to the designed core layer and cladding layer alloy composition, and after melting, degassing, filtering and casting, core layer alloy ingots and cladding layer alloy ingots with a thickness of 520 mm and The clad layer alloy ingot is cast, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com