Computer case shell manufacturing sheet metal machining process

A technology of chassis shell and processing technology, which is applied in the field of sheet metal processing, can solve problems that affect the punching of processing equipment, reduce the use value of punching devices, and cannot meet the use range of the slot holes of the chassis shell, so as to increase stability and improve precision Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

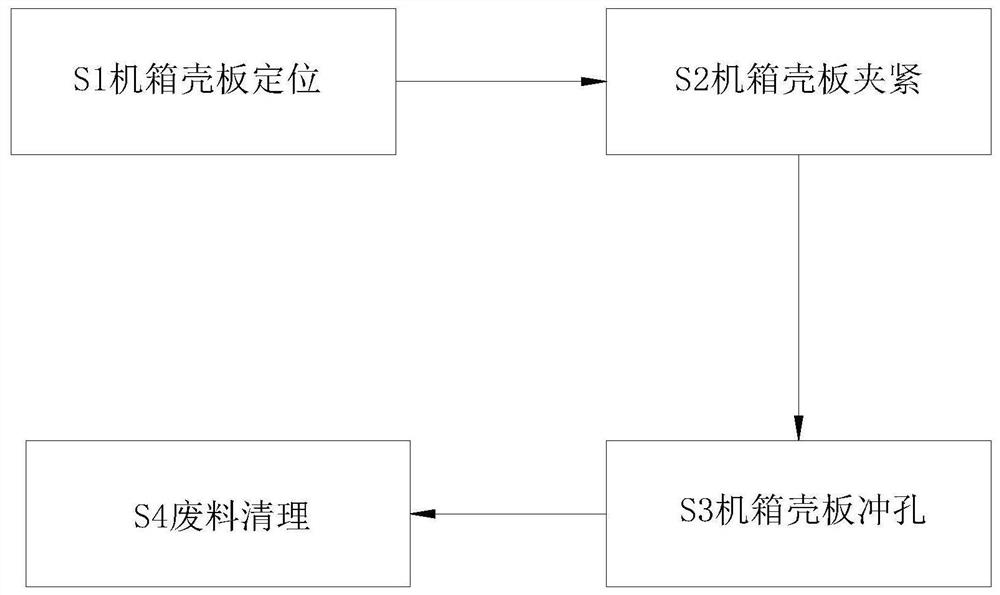

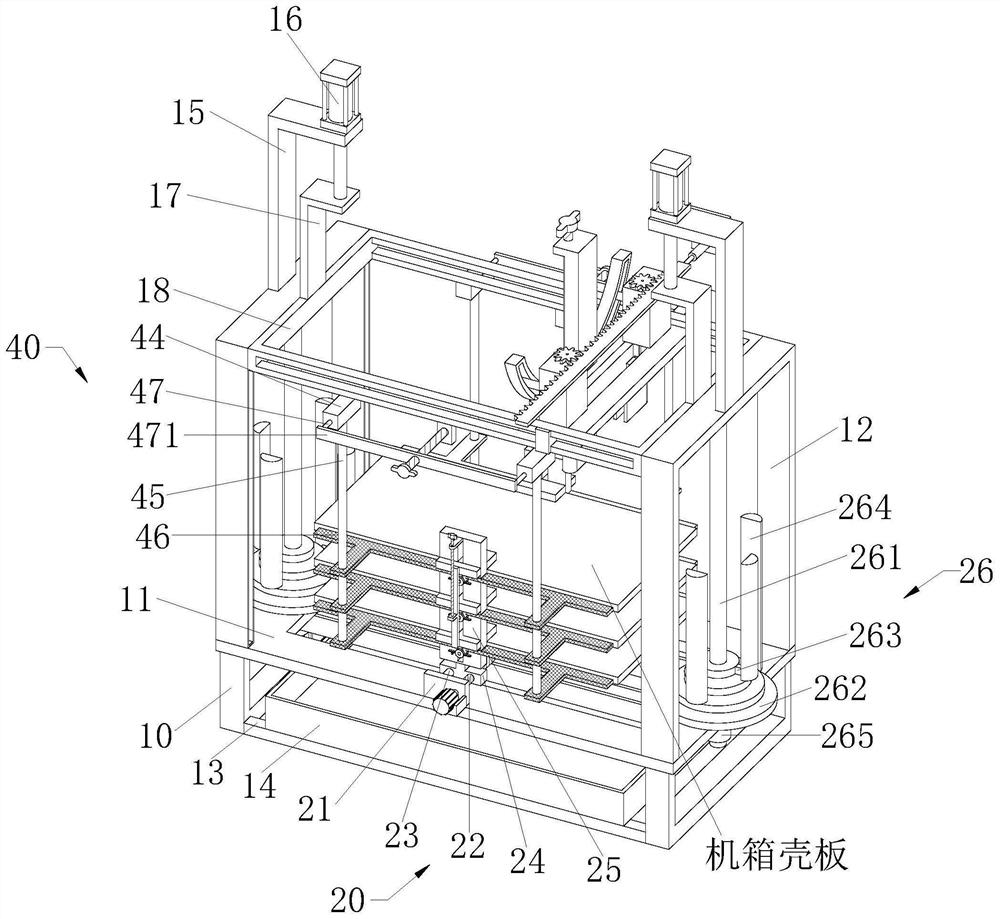

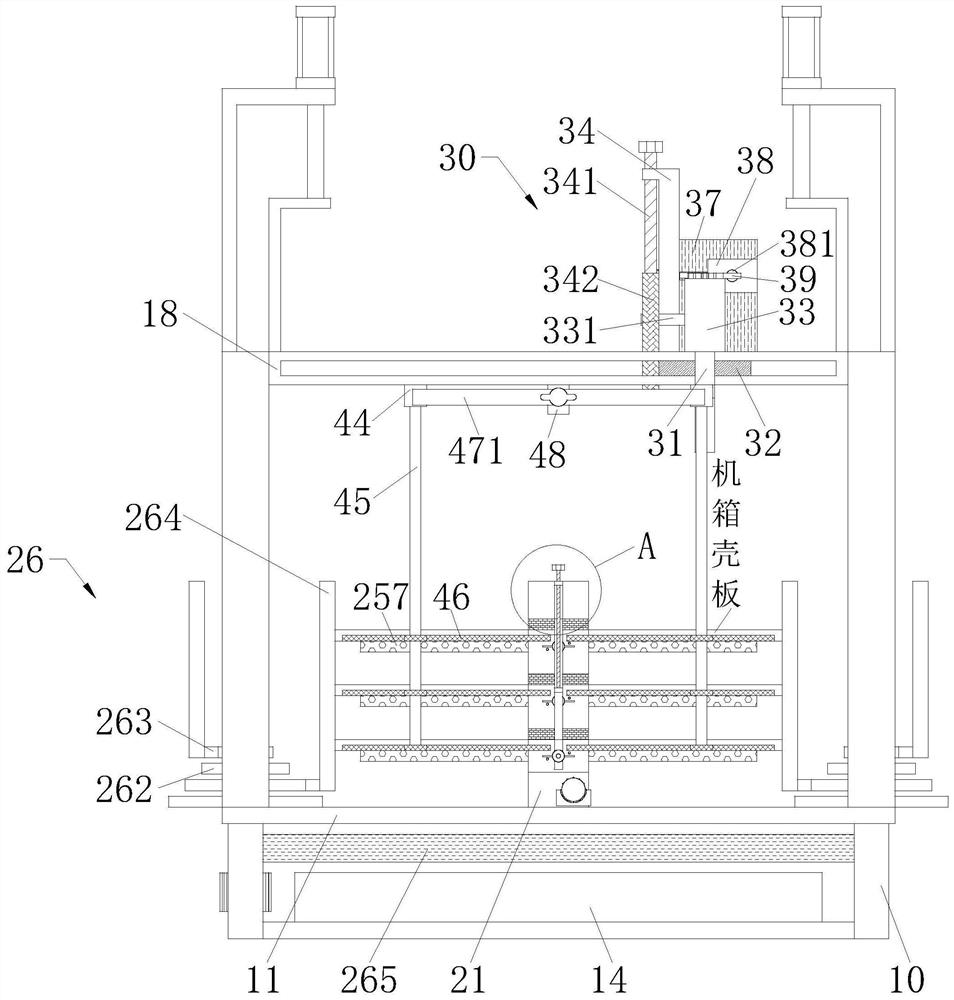

[0045] Such as Figure 2 to Figure 14 As shown, a computer case shell manufacturing sheet metal processing technology, which uses the computer case shell manufacturing sheet metal processing equipment, the equipment includes left and right symmetry and the opening of the upper-arranged 匚-shaped base 10 and two sets of 匚-shaped bases arranged together 10 top of the back-shaped bottom plate 11, the left and right ends of the top of the back-shaped bottom plate 11 are symmetrically provided with gantry frames 12, two sets of support rods 13 are arranged between the horizontal sections of the 匚-shaped base 10, and two groups of support rods 13 are symmetrically arranged front and back, The tops of the two sets of support rods 13 and the bottom of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com