Multi-specification punch

A technology with multiple specifications and punches, applied in the field of stamping, can solve the problems of single punch structure, increase the production cost of enterprises, easy damage, etc., and achieve the effect of improving economic benefits, reducing production costs, and improving buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

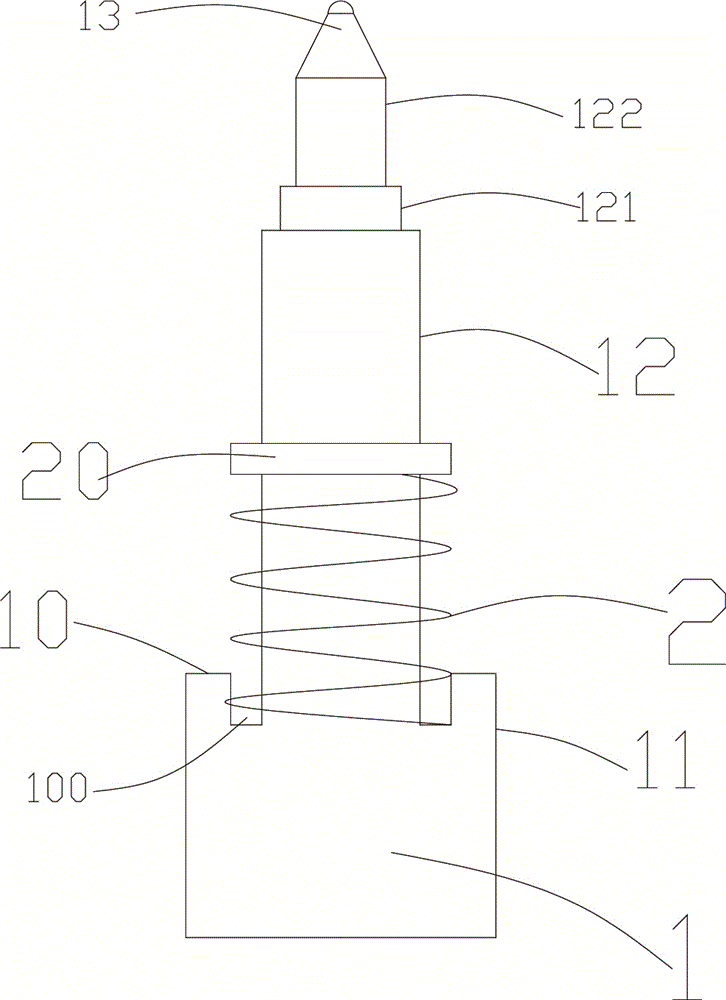

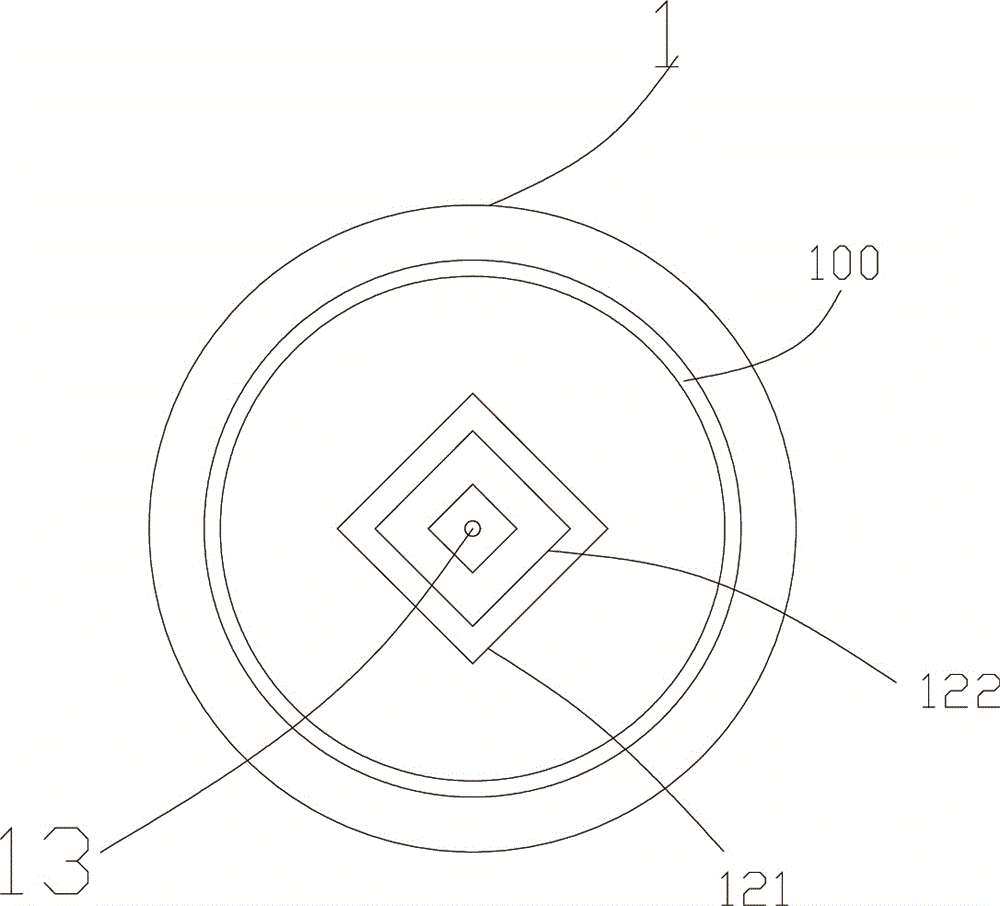

[0010] see figure 1 and figure 2 Shown, a kind of specific embodiment of multi-standard punch of the present invention. A multi-standard punch, including a punch body 1, the punch body 1 is a cylindrical structure, the middle and rear part of the punch body 1 divides the punch body 1 into a front section 11 of the punch and a punch front section 11 through a step 10. The back section 12 of the head, the step 10 is provided with an annular groove 100, and a spring 2 is arranged in the groove 100, and the spring 2 is sleeved on the front section 11 of the punch, and the upper part of the spring 2 is arranged There are end caps 20 . Arranged like this, since the groove on the punch body is provided with a spring, it can play a good buffering effect, and the spring will not shift.

[0011] Further, a first square die 121 and a second...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com