Powder feeding device for powder hydraulic press

A technology of powder hydraulic press and powder feeding device, which is applied in the direction of presses, manufacturing tools, etc., and can solve problems such as affecting pressing and molding, uneven filling of powder raw materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

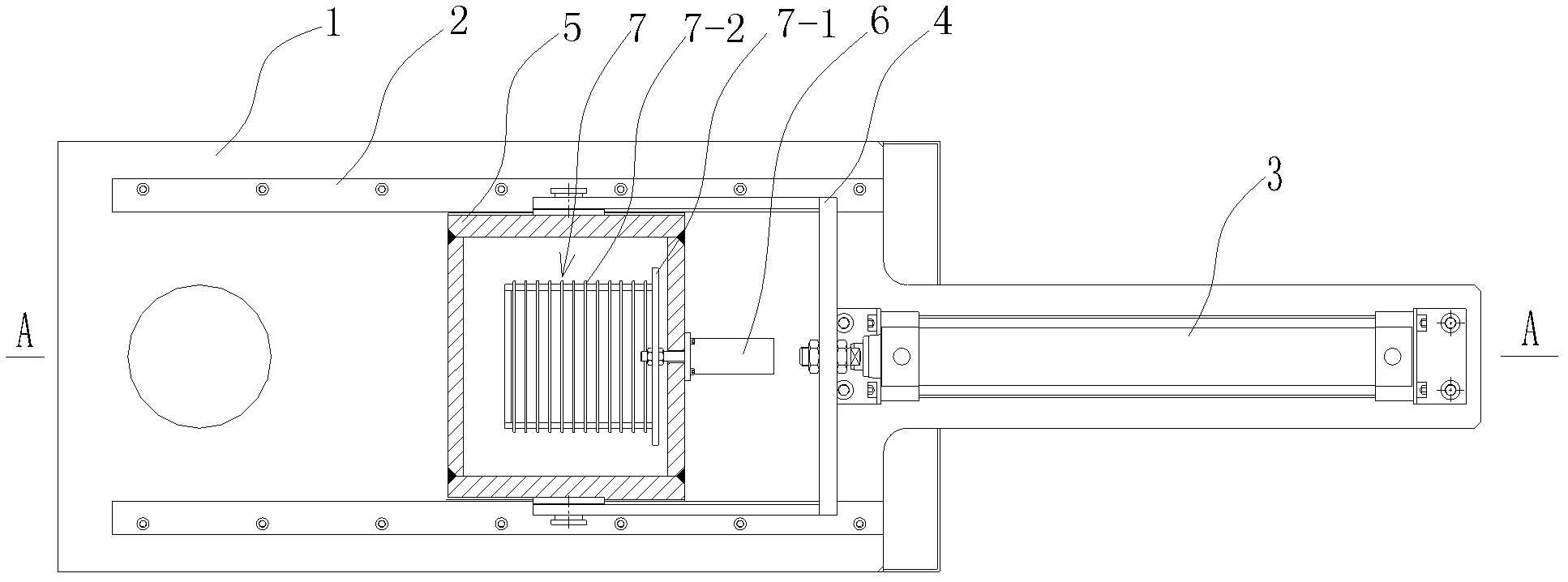

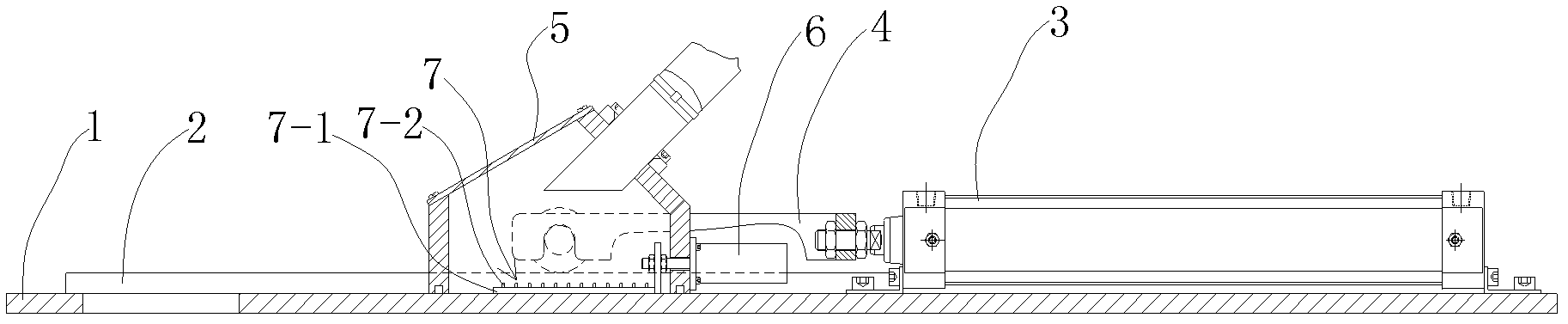

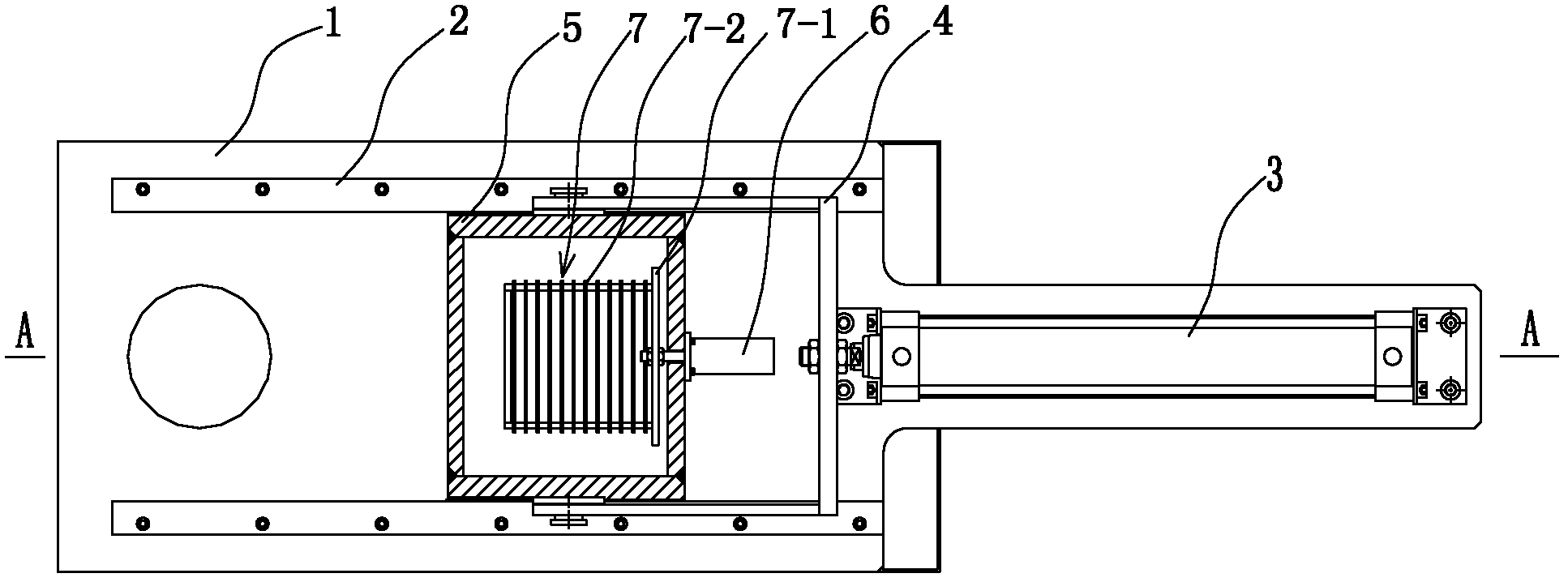

[0012] see figure 1 and 2 , a powder feeding device for a powder hydraulic press, comprising a guide rail 2 fixed on a product support plate 1 and a feeding cylinder 3, a feeding bracket 4 slidably installed on the guide rail, a feeding box 5 fixed on the feeding bracket, and a feeding bracket It is fixedly connected with the push rod end of the feed cylinder, and the side wall of the feed box perpendicular to the guide rail is fixed with a vibration cylinder 6, and the push rod end of the vibration cylinder is fixedly connected with a vibration grid 7, and the vibration grid is located in the feed box. Specifically, the vibration grid is formed by welding steel plates and steel bars, and consists of a frame part 7-1 connected to the vibrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com