Automatic optical fiber gyroscope winding machine and optical fiber winding method

A fiber optic gyroscope and winding machine technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of uneven wiring and gaps, and achieve the effect of uniform wiring and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

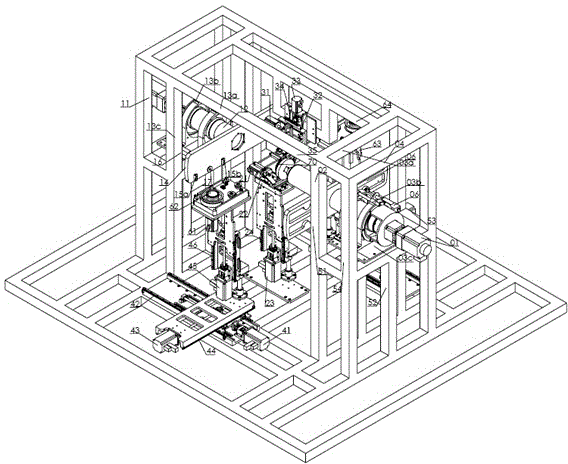

Image

Examples

Embodiment Construction

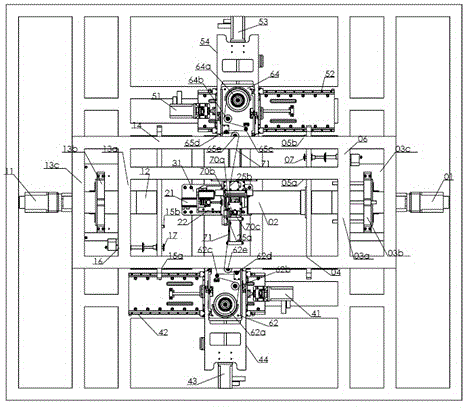

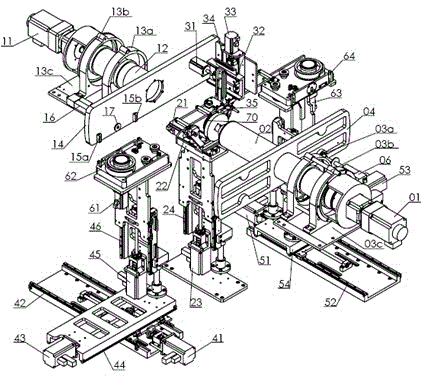

[0034] The present invention will be further described below in conjunction with accompanying drawing:

[0035] First make all servo motors find their origin. Determine the position of 0mm on the respective rails.

[0036] Then optical fiber is put through front pay-off reel 62a, 62b, 62c, 62d, 62e, front guide wheel 25a, take-up reel skeleton 70a, rear guide wheel 25b, rear pay-off reel 65e, 65d, 65c, 65b, 65a. At this time the state is as image 3 , 4 shown.

[0037] After controlling the action of the electric push rod 06, loosen the main shaft clamp spring 07, so that the rear mobile base 50 delays the x-axis guide rail 52 of the base to move to 56 mm, and the delay base y-axis guide rail 54 moves to -51.6 mm. The z-axis guide rail 56 of the rear base moves to 24mm, the x-axis guide rail 52 of the delayed base moves to 74.3mm, the z-axis guide rail 56 of the delayed base moves to 0mm, the rear electric push rod 06 moves, and the spindle card is tightened Spring 07, no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com