Line cutting device capable of guaranteeing uniform line cutting

A tangential and uniform technology, applied in workshop equipment, manufacturing tools, etc., can solve the problems of non-rotation of the scribing knife and uneven scribing, and achieve the effect of even scribing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

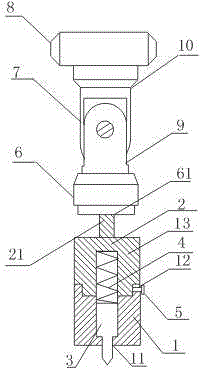

[0018] The thread cutting device that ensures uniform tangent includes a scribing base 7 and a scribing knife 13 installed on the scribing base 7. The scribing base 7 includes a fixing seat 6, a connecting seat 10, and a mounting seat 8 connected to the connecting seat 10. And the upper and lower two blocking pieces 9 that are connected with the fixed seat 6, wherein the upper and lower two blocking pieces 9 are connected with the connecting seat 10 through a rotating shaft; The connected hollow second assembly part 2 and the knife 3, the knife 3 is slidably arranged in the cavity structure formed by the first assembly part 1 and the second assembly part 2, and the bottom of the first assembly part 1 is provided with The installation hole 11 ; the marking knife 13 also includes an elastic element 4 , one end of the elastic element 4 presses against the top of the knife body of the marking knife 3 , and the other end presses against the inner wall of the top of the second assemb...

Embodiment 2

[0021] In this embodiment, on the basis of Embodiment 1, the inner diameter of the first assembly part 1 is equal to the maximum diameter of the blade of the knife 3, and the inner diameter of the mounting hole 11 is smaller than the maximum diameter of the blade of the knife 3.

[0022] The inner diameter of the first assembly part 1 is equal to the maximum diameter of the knife body of the knife 3 , and the effect of limiting the radial shaking of the knife 3 can be achieved during the working process of the knife 3 . The inner diameter of the mounting hole 11 is less than the maximum diameter of the blade body of the scratching knife 3, so that the scratching knife 3 will not fall off therefrom when moving up and down in the clamp.

Embodiment 3

[0024] In this embodiment, on the basis of Embodiment 1, the elastic element 4 is a spring.

[0025] An elastic element 4 is arranged above the knife 3 , the elastic element 4 is a spring, one end of the spring is against the top of the knife 3 , and the other end is against the inner wall of the top of the second assembly part 2 . In the initial state, the lowering fixture lowers the scribing knife 3 to a preset position and compresses the spring to a certain extent. When the scribing knife 3 touches the depression on the scribing surface, the scribing knife 3 is pushed out by the restoring force of the spring. Touching the concave surface, when the scribing knife 3 touches the convex part of the scribing surface, the scribing knife 3 is lifted, and the spring is compressed again and at the same time gives the scribing knife 3 a reaction force to make the scribing knife 3 complete the work of scribing, thus The self-adjustment function of the scribing knife 3 in the scribing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com