Winding method for integrated magnetic component winding

A winding method and technology of components, applied in electrical components, transformer/inductor coil/winding/connection, transformer/inductor components, etc., can solve the problem of poor electrical performance and consistency of products, inability to control tension, Problems such as uneven wiring, to achieve the effect of improving consistency and stability, stable internal structure of the coil, and uniform wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

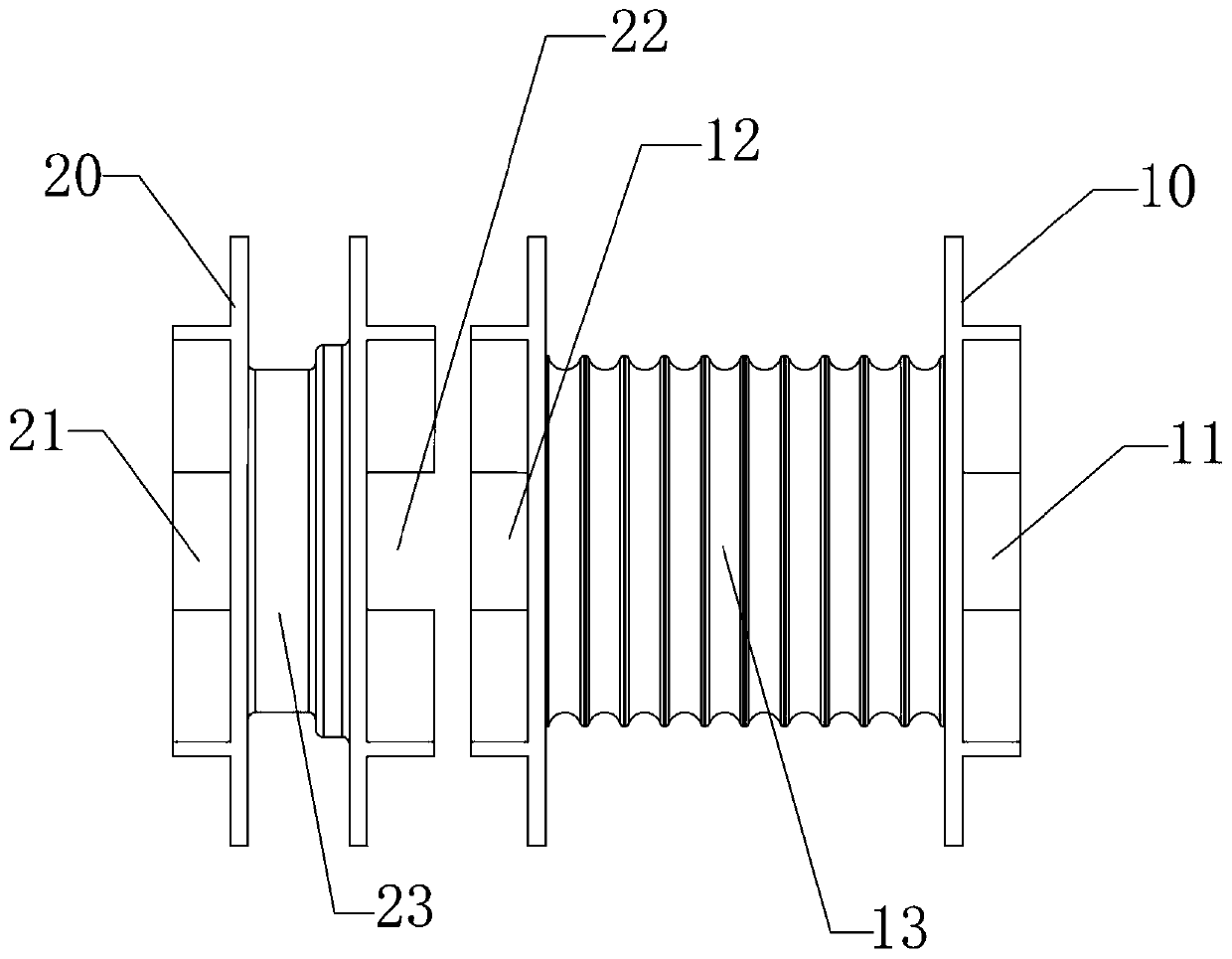

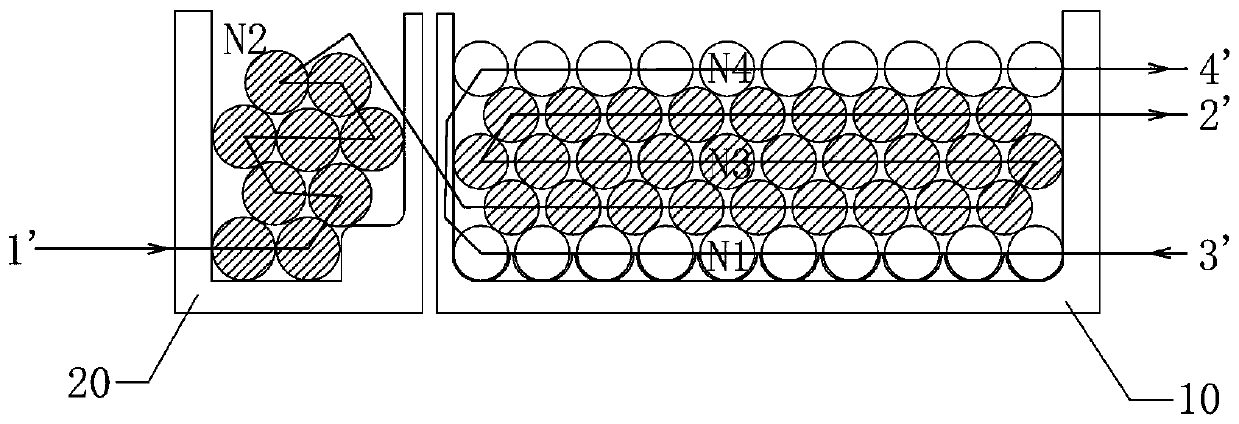

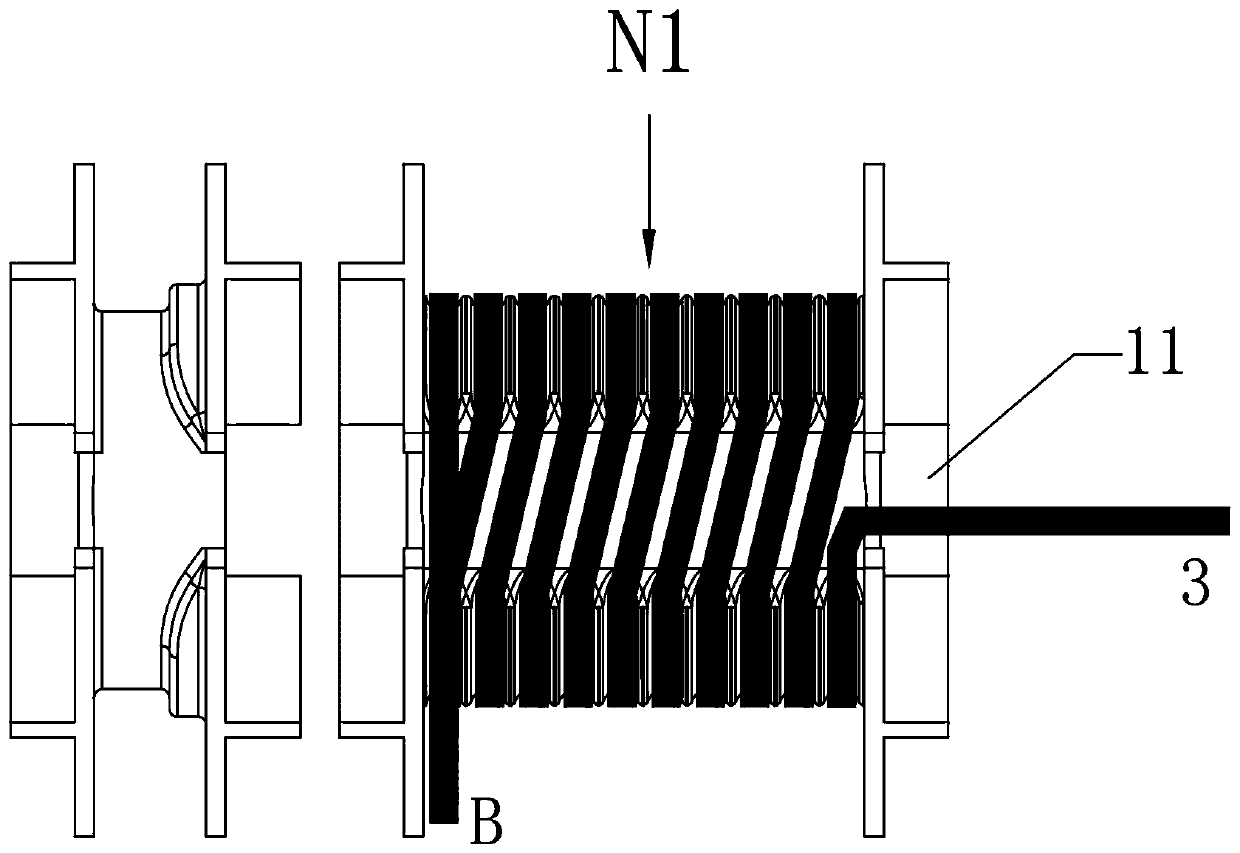

[0018] Current magnetic components require not only small size and high integration, but also higher power density and more stable electrical performance. For the integrated magnetic components that share the magnetic core of the transformer and the inductor, the winding requirements are relatively high when making the winding. The winding method needs to increase the power density as much as possible, and at the same time ensure the stability of the electrical performance and the consistency of the product. Good sex. In view of this, the present invention proposes a winding method for windings of transformers and inductance integrated magnetic components, by controlling the transformer bobbins and inductance bobbins to rotate separately / simultaneously on the automatic winding machine to complete the automatic winding of multi-layer coils with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com