High-temp. superconductive cable winding machine

A high-temperature superconducting and winding machine technology, which is applied to superconducting devices, conductor/cable insulation, superconducting/high-conducting conductors, etc. Conductivity, easy overlap and other issues, to achieve the effect of simple and convenient winding operation control, uniform wire tension, and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

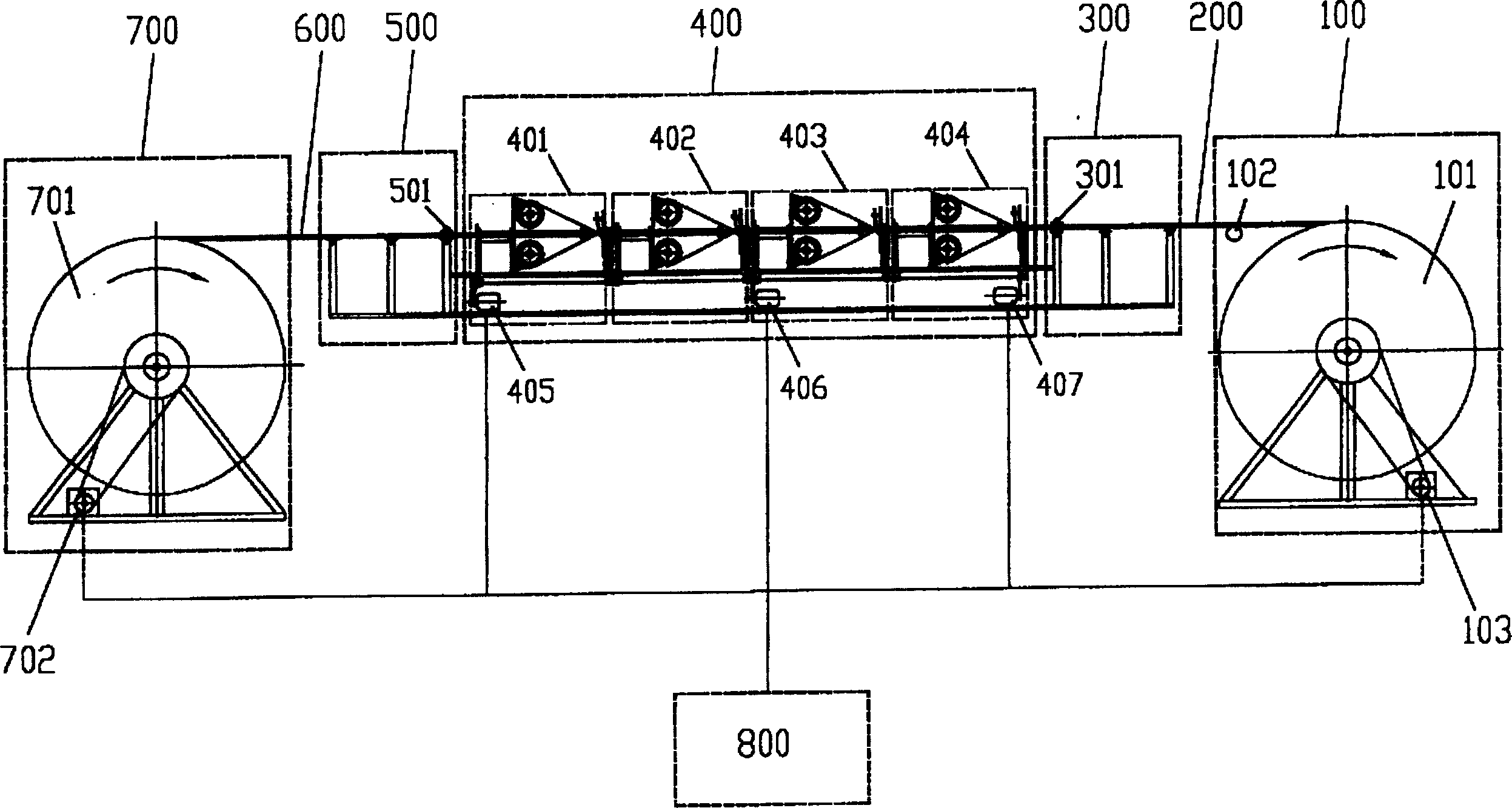

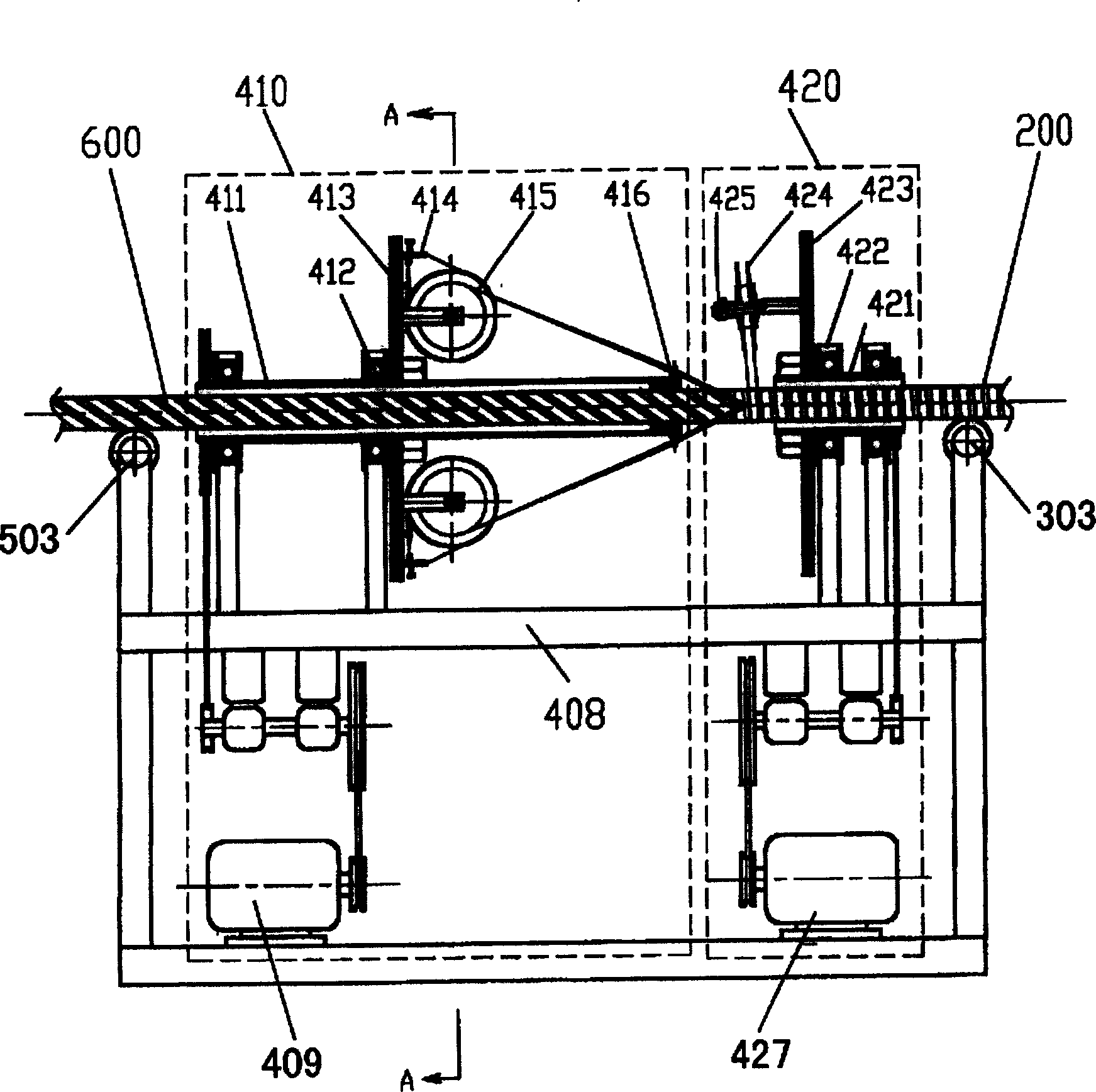

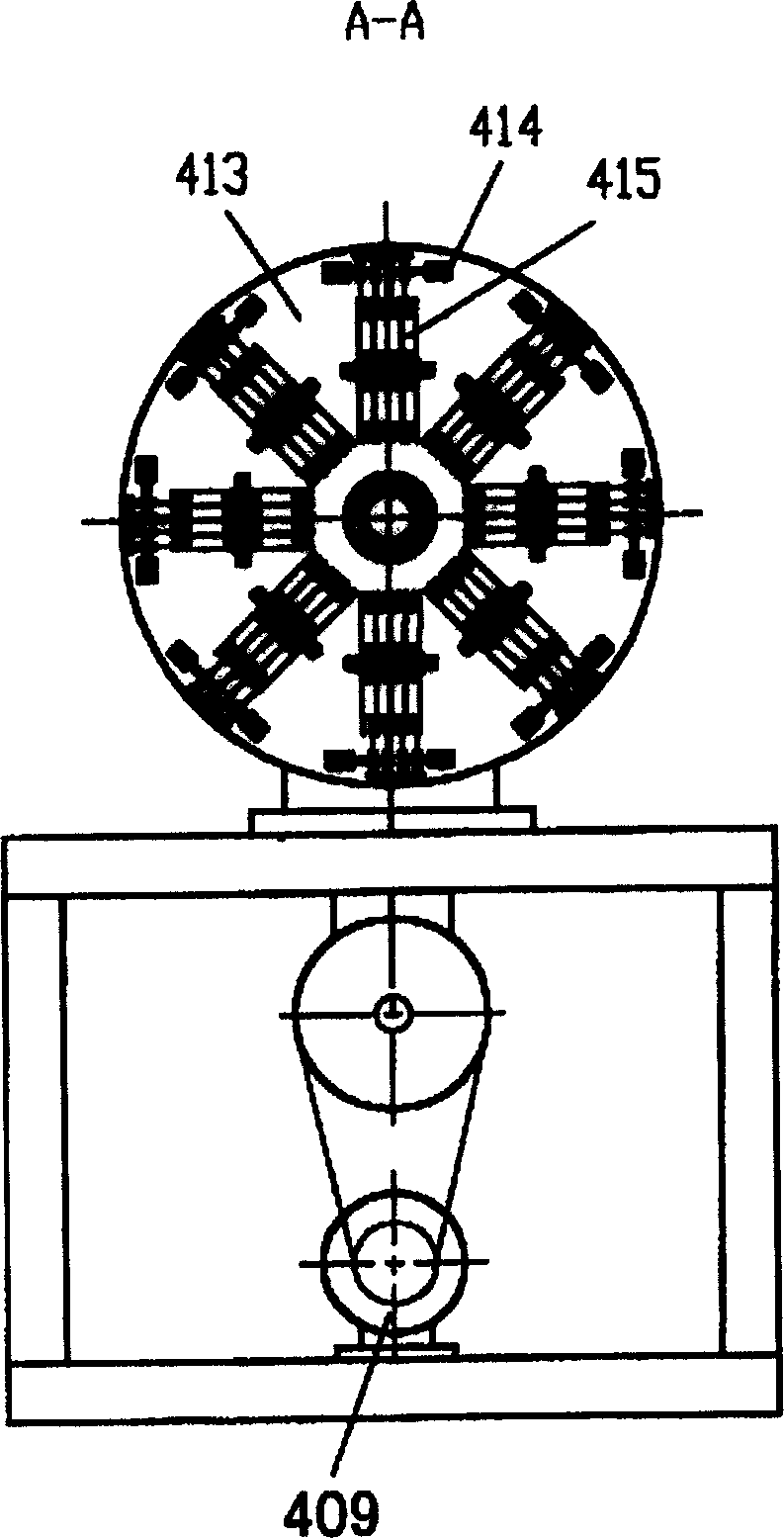

[0032] see first figure 1 . The high-temperature superconducting cable winding machine of the present invention includes a front-end cable take-up and dragging part 100; a wound cable section 200; a front support frame 300 for supporting the wound cable section; and a host component 400 located in the middle section. It also includes multiple winding groups, and the general cable is four layers, so the winding machine shown here is four winding groups, namely 401, 402, 403, 404; the rear support frame 500 for supporting the cable skeleton; The cable skeleton 600 is drawn out from the straightening force part 700 at the rear end, and the section thereof passes through the host part and connects with the front cable; the computer control part 800 for manipulating the operation of the whole machine. Among the figure, 405, 406, 407 are the stepper moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com