Automobile with one-time formed plastic shell

A technology for plastic shells and car shells, which is applied in the direction of vehicle components, upper structure sub-assemblies, and connections between upper structure sub-assemblies, which can solve the problems of increased costs and manufacturing processes, poor surface performance of products, and problems in the manufacturing process. cumbersome and other problems, to achieve the effect of reducing production costs, reducing weight, and reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

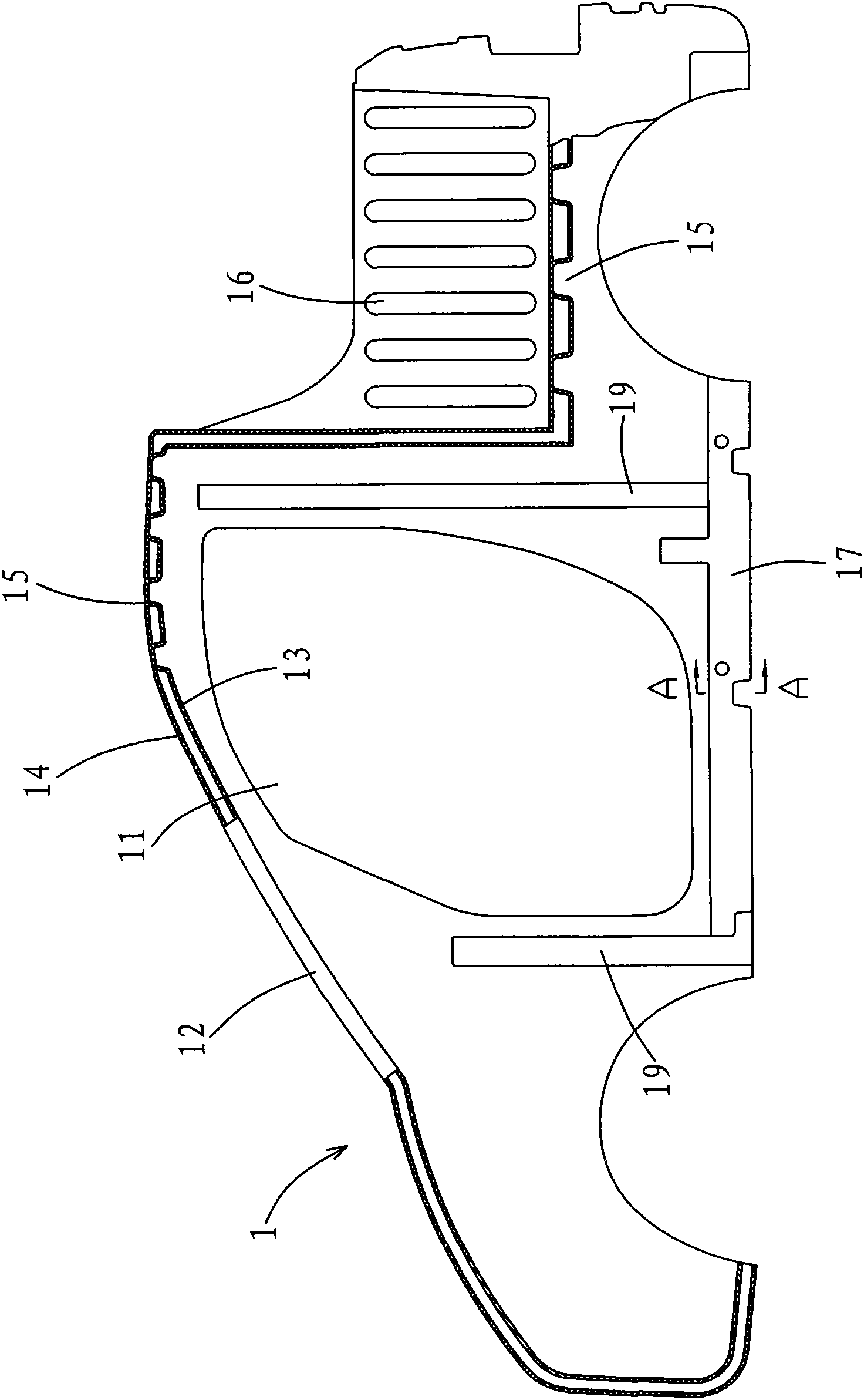

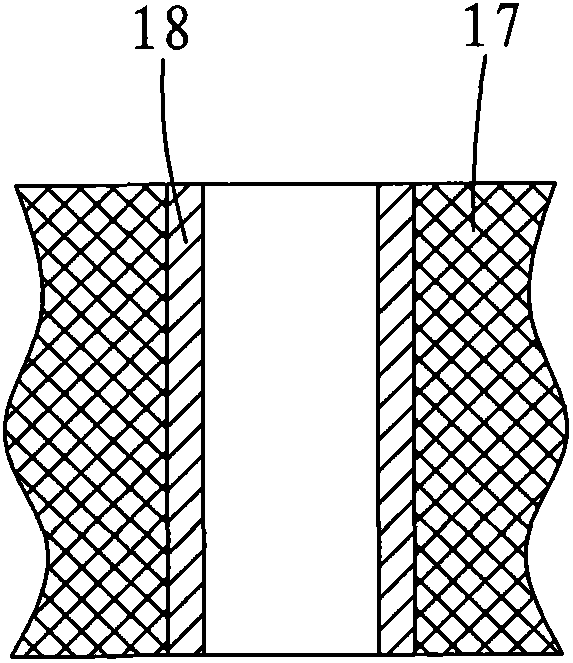

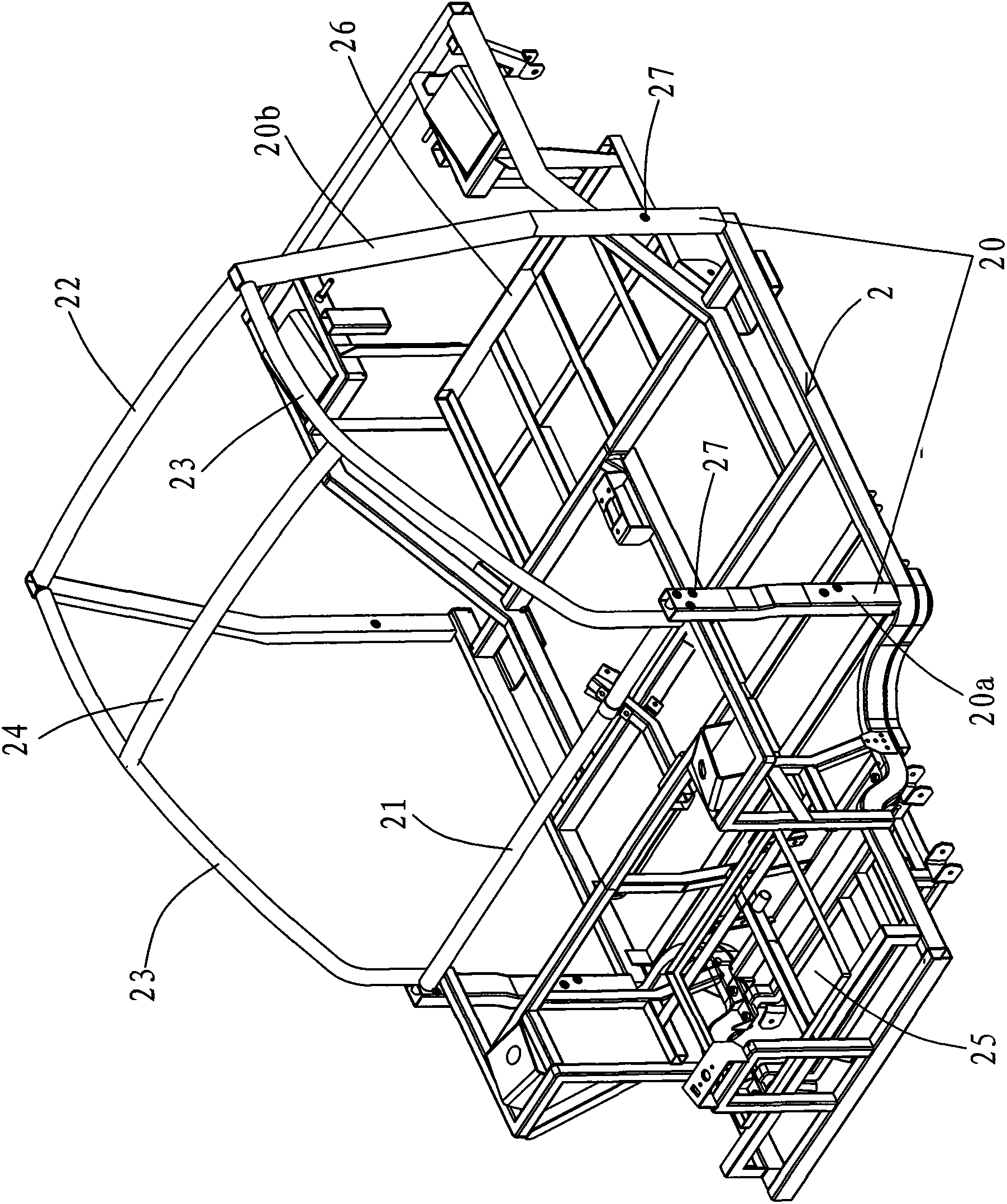

[0022] see figure 1 , figure 2 with image 3 According to the one-time molding plastic car shell automobile provided by the present invention, it includes a vehicle body 1 and a chassis 2. The chassis 2 is welded by aluminum alloy pipes, magnesium alloy pipes or iron pipes. A hollow double-layer plastic shell with door mounting holes 11 and window mounting holes 12, a plurality of kiss ribs 15 formed between the inner wall 13 and the outer wall 14 of the hollow double-layer plastic shell, The outer surface of the outer wall 14 or the inner wall 13 of the hollow double-layer plastic shell is formed with several convex reinforcing ribs 16, and the lower end of the outer surface of the inner wall 13 of the hollow double-layer plastic shell is formed with a chassis embedded Groove 17, several screw sleeves 18 are pre-embedded on the chassis insertion groove 17, the chassis 2 is embedded in the chassis insertion groove 17 and is screwed with it, the outer surface of the inner la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com