Composite polyurethane foam sheet produced by using hard foam wastes, and preparation method thereof

A composite polyurethane and rigid foam technology, applied in the field of composite polyurethane foam boards, can solve the problems of rigid foam without suitable treatment methods, limited types of recycled materials, and unsuitable for large-scale use, etc., to achieve low density and high utilization rate , The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

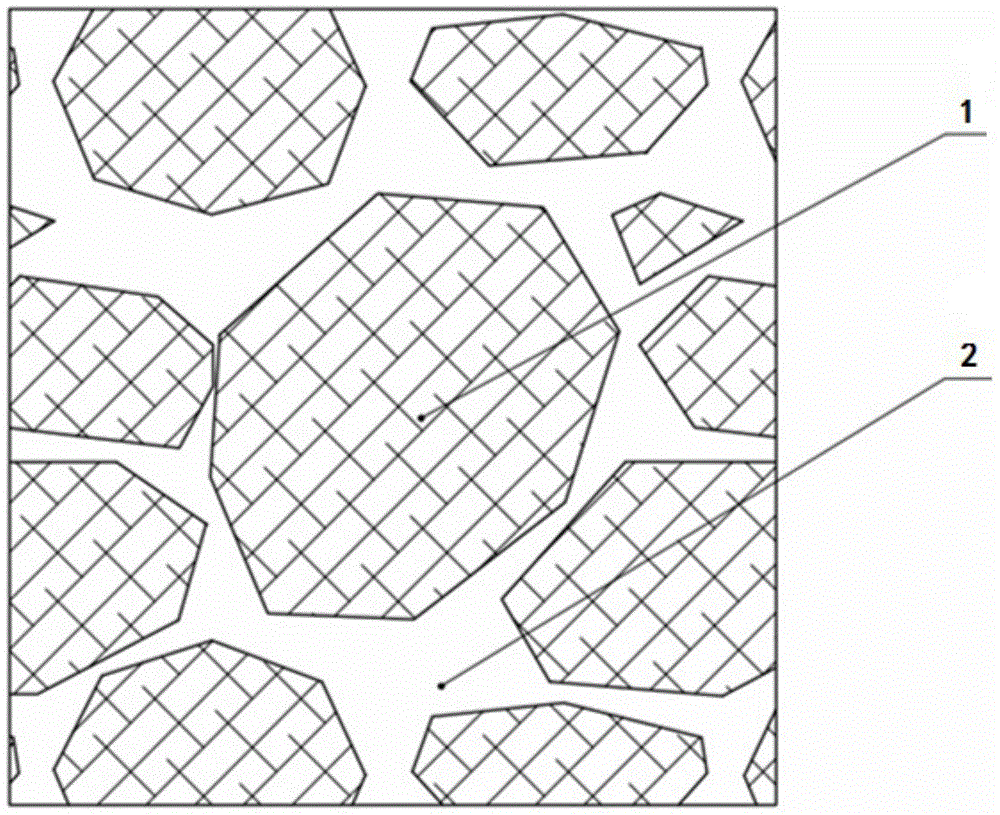

Image

Examples

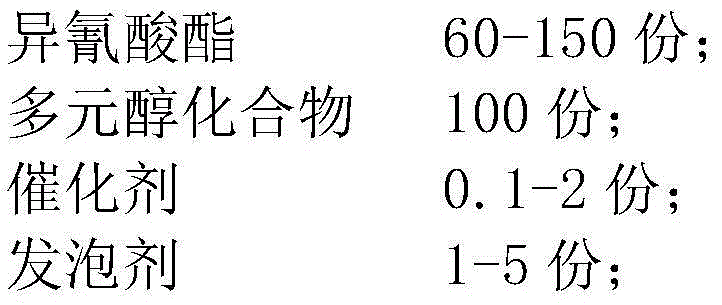

Embodiment 1

[0031] Crush the rigid polyurethane foam board into blocks and granules, the maximum size of which does not exceed 55cm, and put 30 kg of waste blocks and granules of different sizes into a mold with a size of 1.1m x 1.1m x 0.6m to ensure the presence of fillers There must be a certain gap, and the height cannot exceed the height of the mold. Weigh 100 parts by weight of diphenylmethane diisocyanate (MDI), 100 parts by weight of polyether polyol compound, 4 parts by weight of water and 1 part by weight of organotin compound, place in a mechanical stirrer and stir evenly, and the mixed solution is Fill the mold in the form of spray within 300s to ensure that the mixed liquid can completely fill the waste void. Then seal the mold, control the mold temperature at 20-40°C, and remove the mold after 20 minutes to obtain a composite polyurethane foam block with a block weight of 36 kilograms. The block can then be cut into slabs or other shaped products. The leftovers produced can...

Embodiment 2

[0033] Crush polystyrene foam boards into blocks and granules, the maximum size of which does not exceed 55cm, and put 16 kg of waste blocks and granules of different sizes into a mold with a size of 1.1m×1.1m×0.6m to ensure the presence of fillers There must be a certain gap, and the height cannot exceed the height of the mold. Weigh 130 parts by weight of polymethylene polyphenyl isocyanate, 100 parts by weight of polyether polyol compound, 4 parts by weight of surfactant, 4 parts by weight of water, 1 part by weight of organotin compound and 8 parts by weight of ten A mixture of brominated diphenylethane and antimony trioxide (the weight ratio of decabromodiphenylethane to antimony trioxide is 3:1), placed in a mechanical stirrer and stirred evenly, and the mixture was sprayed within 120s Fill the mold to ensure that the mixture can completely fill the waste voids. Then seal the mold, control the mold temperature at 20-40°C, and remove the mold after 20 minutes to obtain a...

Embodiment 3

[0035] Crush the rigid polyurethane foam board into blocks and granules, the maximum size of which does not exceed 55cm, and put 30 kg of waste blocks and granules of different sizes into a mold with a size of 1.1m x 1.1m x 0.6m to ensure the presence of fillers There must be a certain gap, and the height cannot exceed the height of the mold. Weigh 75 parts by weight of polymethylene polyphenyl isocyanate, 100 parts by weight of polyether polyol compound, 4 parts by weight of water, 1 part by weight of organotin compound, 4 parts by weight of surfactant, 3 parts by weight of carbon The black powder and 2 parts by mass of antioxidant 1010 were placed in a mechanical stirrer and stirred evenly, and the mixed solution was filled into the mold in the form of spray within 120s to ensure that the mixed solution could completely fill the waste voids. Then seal the mold, control the mold temperature at 20-40°C, and remove the mold after 20 minutes to obtain a composite polyurethane fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

| dimensional stability | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com