High-iron special flame-resistant polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof and coating technology, which is applied in polyurea/polyurethane coatings, fireproof coatings, coatings, etc., can solve the problems of non-fireproof, flame-retardant, low-temperature flexibility, etc., and achieve easy end closure, low human toxicity, and good extensibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A component: polyether polyol N220 40 parts

[0046] Polyether polyol N330 35 parts

[0047] 22 parts of diphenylmethane diisocyanate (MDI)

[0048] B component: liquid filler (petroleum resin C5) 35 parts

[0049] Composite curing agent (MOCA / N220) 45 parts (7N MOCA / 1N OH )

[0050] Powder filler (light calcium 800 mesh) 25 parts

[0051] Catalyst organotin 0.01% of prepolymer

[0052] UV absorber UV531, 1 part of material B

[0053] Antioxidant 264, 1 part of material B

[0054]Flame Retardant Chlorinated Paraffin-70, 12 parts

[0055] 10 parts dibutyl phthalate

[0056] Preparation:

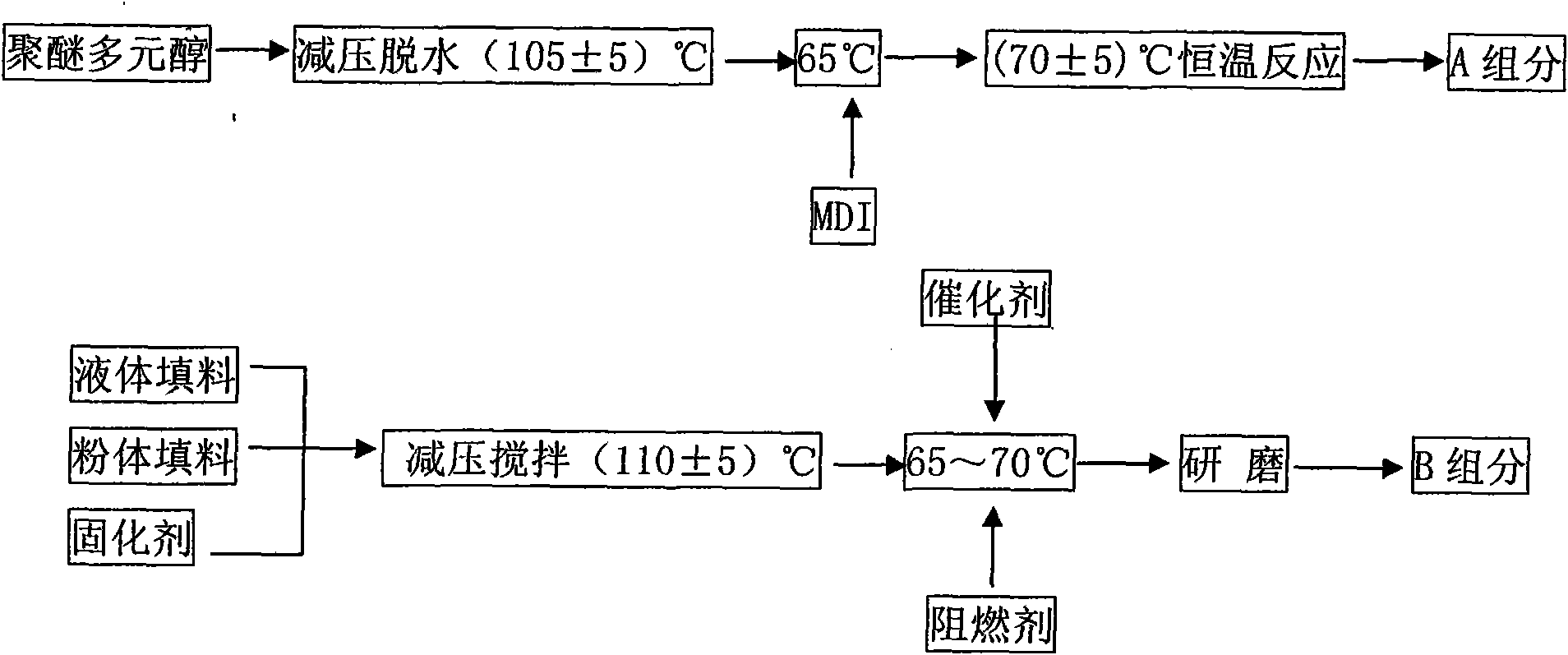

[0057] a. Add mixed polyether (N220, N330) into a jacketed reactor with stirring, heat it to (105±5)°C for vacuum dehydration for 1 hour, then lower it to below 60°C, add metered MDI, and react After 30 minutes, continue to raise the temperature to (70±5)°C, react at a constant temperature for 3 hours, cool down to below 60°C, and pack it out to obtain the isocyanate group-t...

Embodiment 2

[0063] A component:

[0064] Polyether polyol N220 20 parts

[0065] Polyether polyol N330 60 parts

[0066] 28 parts of diphenylmethane diisocyanate (MDI)

[0067] B component:

[0068] Liquid filler (petroleum resin C5) 30 parts

[0069] Composite curing agent (MOCA / N220) 45 parts (7N MOCA / 1N OH )

[0070] Powder filler (light calcium 800 mesh) 25 parts

[0071] Catalyst organotin 0.01% of prepolymer

[0072] UV absorber UV531, 3% of material B

[0073] Antioxidant 264, 5% of material B

[0074] Flame Retardant Chlorinated Paraffin-70, 15 parts

[0075] Dioctyl phthalate 8 parts

[0076] The preparation method is the same as in Example 1.

Embodiment 3

[0078] A component:

[0079] Polyether polyol N220 60 parts

[0080] Polyether polyol N330 20 parts

[0081] 35 parts of diphenylmethane diisocyanate (MDI)

[0082] B component:

[0083] Liquid filler (petroleum resin C5) 35 parts

[0084] Composite curing agent (MOCA / N220) 60 parts (9N MOCA / 1N OH )

[0085] Powder filler (light calcium 800 mesh) 25 parts

[0086] Catalyst organotin 0.01% of prepolymer

[0087] UV absorber UV531, 2% of material B

[0088] Antioxidant 264, 5% of material B

[0089] Flame Retardant Chlorinated Paraffin-70, 12 parts

[0090] Dioctyl phthalate 10 parts

[0091] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com