Preparation method and application of compound cimicifugamide

A technology of cimicamide and compound, which is applied in the field of preparation of glycoside compound cimicamide, can solve the problems of difficult development, difficulty in obtaining standard samples, and few researches on glycoside-bound aroma components, and achieves good effect and low volatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

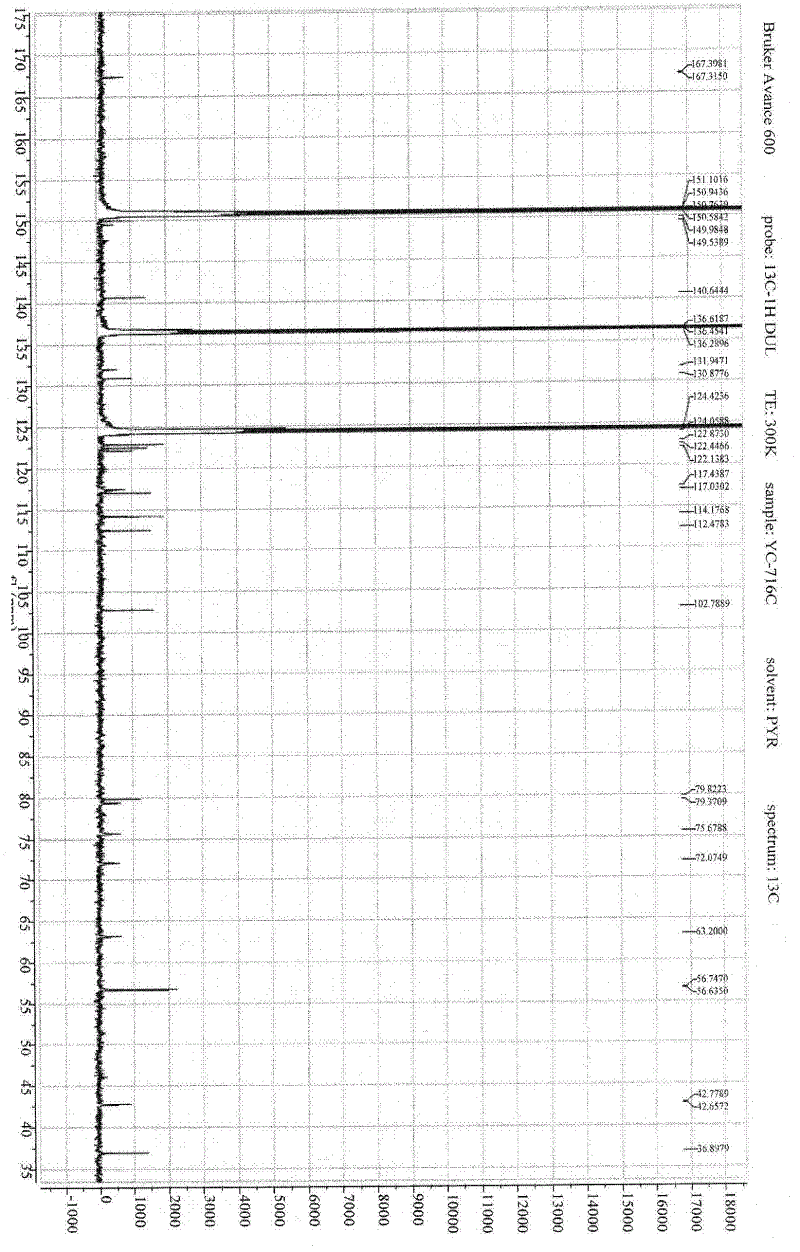

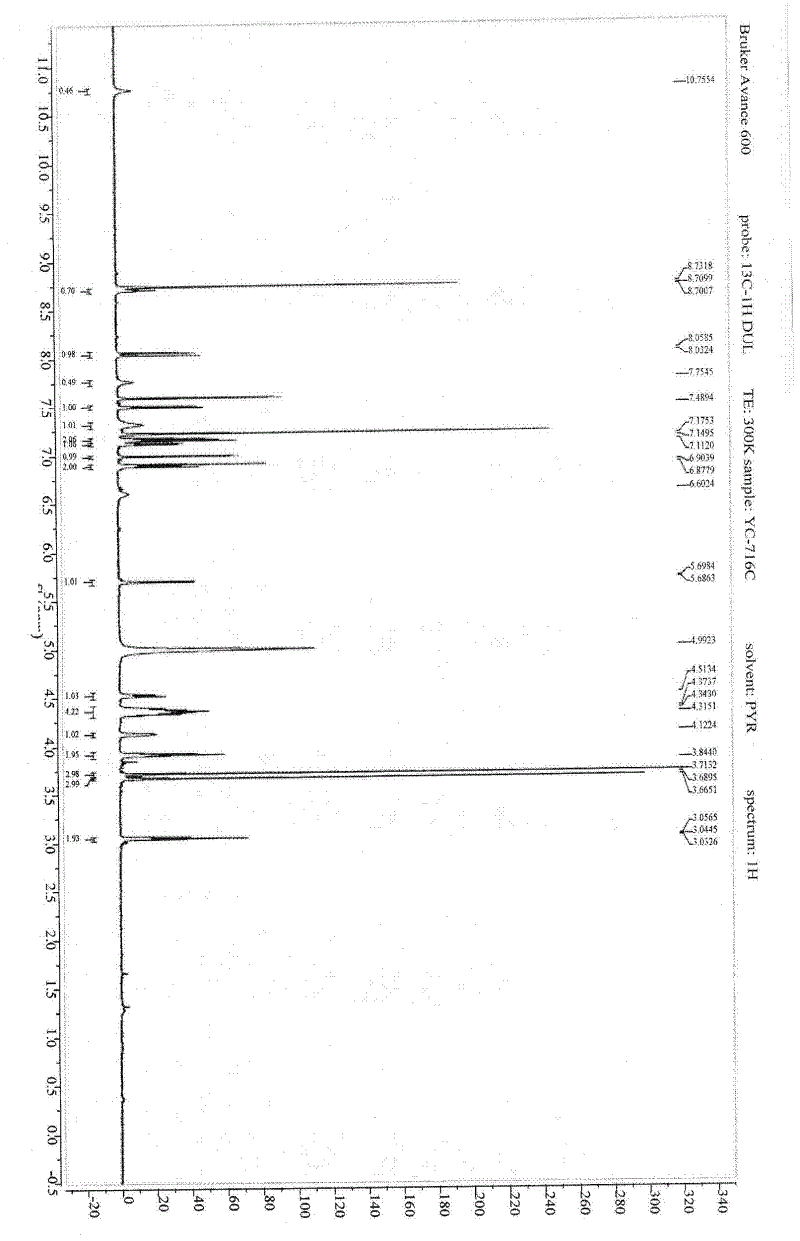

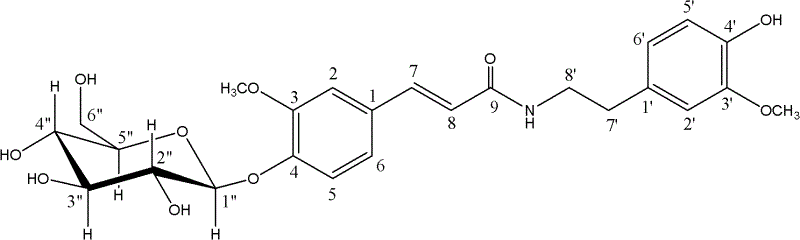

Image

Examples

Embodiment 1

[0033] Take 20 kilograms of tobacco leaves after baking, heat extract three times with 95% ethanol, the heat extraction temperature is 60 ℃, the dosage of 95% ethanol is respectively 12, 10 and 8 times of the weight of tobacco leaves, and the extraction time is respectively 180, 120 and 90 minutes , the extract was concentrated under reduced pressure, dissolved in water, then extracted with petroleum ether, ethyl acetate and n-butanol in sequence, and the extract was concentrated under reduced pressure. The n-butanol extract was roughly separated by resin, and then separated by 300-mesh silica gel and C-18 reverse-phase silica gel column chromatography to obtain 25 mg of cimicamide.

Embodiment 2

[0035] Get 20 kilograms of tobacco leaves after baking, heat extraction with methanol three times, the temperature of heat extraction is 50 ℃, the dosage of methanol is respectively 12, 10 and 8 times of the weight of tobacco leaves, the extraction time is respectively 120, 90 and 60 minutes, and the extracting solution reduces After concentrated under pressure, add water to dissolve, then extract with petroleum ether, ethyl acetate and n-butanol respectively, and concentrate the extract under reduced pressure. The n-butanol extract was roughly separated by resin, and then separated by 150 mesh silica gel and C-18 reverse phase silica gel column chromatography to obtain 27 mg of cimicamide.

Embodiment 3

[0037] Take 20 kg of cured tobacco leaves, heat extract three times with n-butanol, the heat extraction temperature is 70°C, the amount of n-butanol is 12, 10 and 8 times the weight of the tobacco leaves respectively, and the extraction time is 120, 90 and 60 minutes respectively , the extract was concentrated under reduced pressure, dissolved in water, then extracted with petroleum ether, ethyl acetate and n-butanol, and the extract was concentrated under reduced pressure. The n-butanol extract was roughly separated by resin, and then separated by 60 mesh silica gel and C-18 reverse phase silica gel column chromatography to obtain 21 mg of cimicamide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com