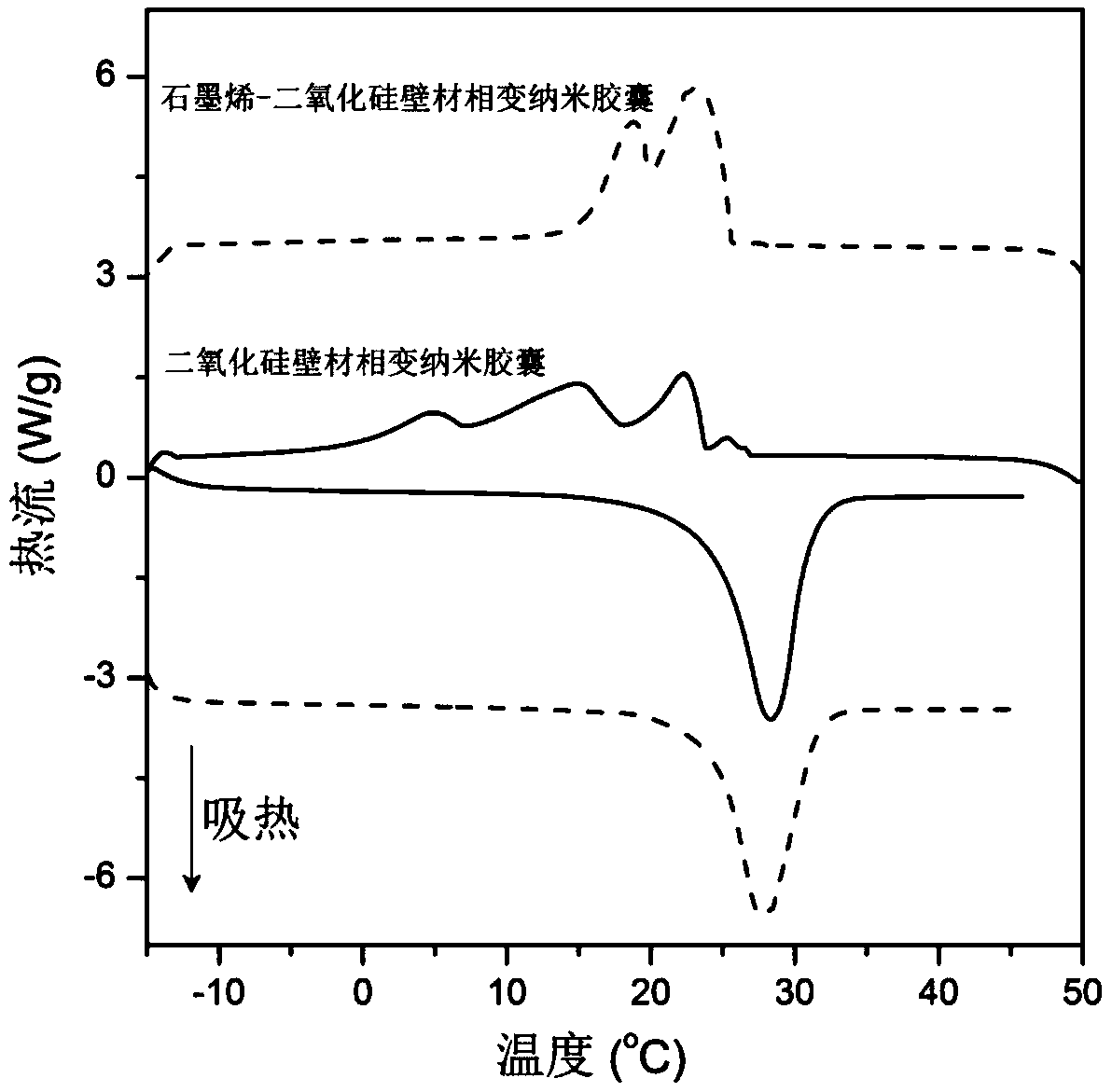

Graphene-silicon dioxide composite wall-material phase-change nanocapsule and preparation method thereof

A nanocapsule and silicon dioxide technology, applied in microcapsule preparations, chemical instruments and methods, microsphere preparation, etc., can solve the problems of inability to form microcapsules, decrease in phase change enthalpy, decrease in phase change enthalpy, etc. The effect of cold phenomenon, thermal conductivity improvement, and thermal conductivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In a 10 mL sample bottle, add 0.1 g sodium lauryl sulfate, 4 mL deionized water, and 30 mg graphene powder, and then ultrasonically disperse for 30 min to form a stable graphene dispersion.

[0037] In a 100mL beaker, add 2g of n-octadecane, 1g of methyltrimethoxysilane, and 2g of ethyl orthosilicate to form an oil phase after being miscible. Then 0.328 g of cetyltrimethylammonium bromide was added to the oil phase. In another 100mL beaker, add 28.5mL of water and 14.2mL of ethanol in sequence, and make it miscible as the water phase. After the water phase was added to the oil phase and mixed, the mixture was emulsified for 2 minutes with a high-speed shearer at a speed of 13000 r / min to form an oil-in-water emulsion, and then ultrasonicated for 5 minutes to form a stable fine emulsion. The miniemulsion was transferred to a 100 mL round bottom flask and placed in an oil bath at 35 °C. The graphene dispersion was added dropwise into the miniemulsion, and then 2 mL of e...

Embodiment 2

[0040] In a 50 mL sample bottle, add 0.5 g sodium lauryl sulfate, 20 mL deionized water, and 150 mg graphene powder, and then ultrasonically disperse for 1 h to form a stable graphene dispersion.

[0041] In a 500mL beaker, add 10g of n-octadecane, 5g of methyltrimethoxysilane, and 10g of ethyl orthosilicate to form an oil phase after being miscible. Then 1.64 g of cetyltrimethylammonium bromide were added to the oil phase. In another 500mL beaker, add 142.5mL of water and 71mL of ethanol in sequence, and use it as the water phase after being miscible. After the water phase was added to the oil phase and mixed, the mixture was emulsified by a high-speed shearer at a speed of 13000r / min to form an oil-in-water emulsion, and then ultrasonicated by an ultrasonic breaker for 10 minutes to form a stable fine emulsion. The miniemulsion was transferred to a 500 mL round bottom flask and placed in an oil bath at 35 °C. The graphene dispersion was added dropwise into the miniemulsion...

Embodiment 3

[0043] In a 50mL sample bottle, 0.1g sodium lauryl sulfate, 11mL deionized water, 100mg graphene powder, and then ultrasonically disperse for 30min to form a stable graphene dispersion.

[0044] In a 100mL beaker, add 2g of n-octadecane, 1g of methyltrimethoxysilane, and 2g of ethyl orthosilicate to form an oil phase after being miscible. Then 0.328 g of cetyltrimethylammonium bromide was added to the oil phase. In another 100mL beaker, add 28.5mL of water and 14.2mL of ethanol in sequence, and make it miscible as the water phase. After the water phase was added to the oil phase and mixed, the mixture was emulsified for 2 minutes with a high-speed shearer at a speed of 13000 r / min to form an oil-in-water emulsion, and then ultrasonicated for 5 minutes to form a stable fine emulsion. The miniemulsion was transferred to a 100 mL round bottom flask and placed in an oil bath at 35 °C. The graphene dispersion was added dropwise into the miniemulsion, and then 5.5 mL of ethanol wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com