Light-emitting device

一种发光装置、发射出的技术,应用在电气元件、电固体器件、电路等方向,能够解决接合线破裂、改变LED芯片发光特性等问题,达到降低线性膨胀系数的差异、减少组件或部件数、减少反射损失的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

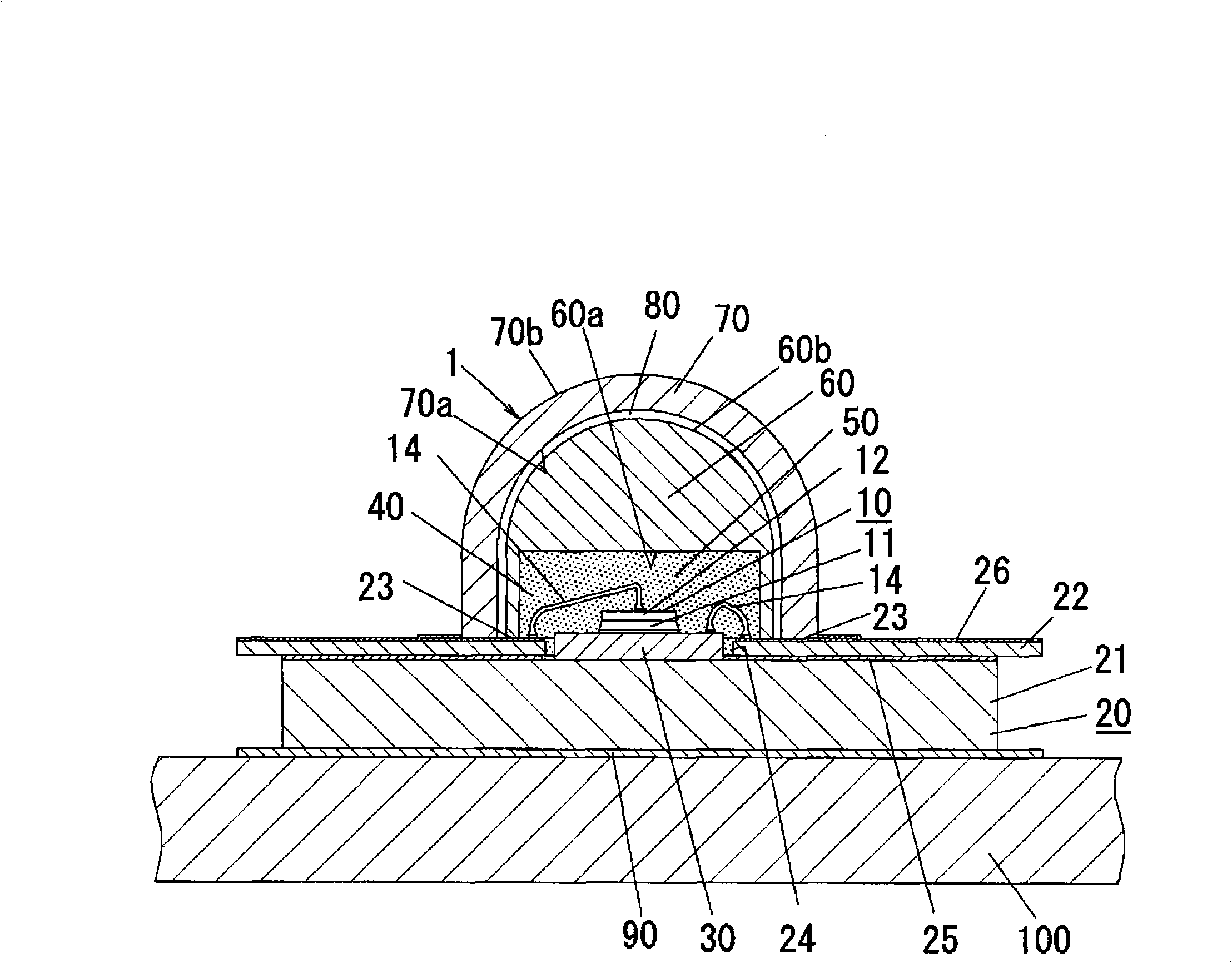

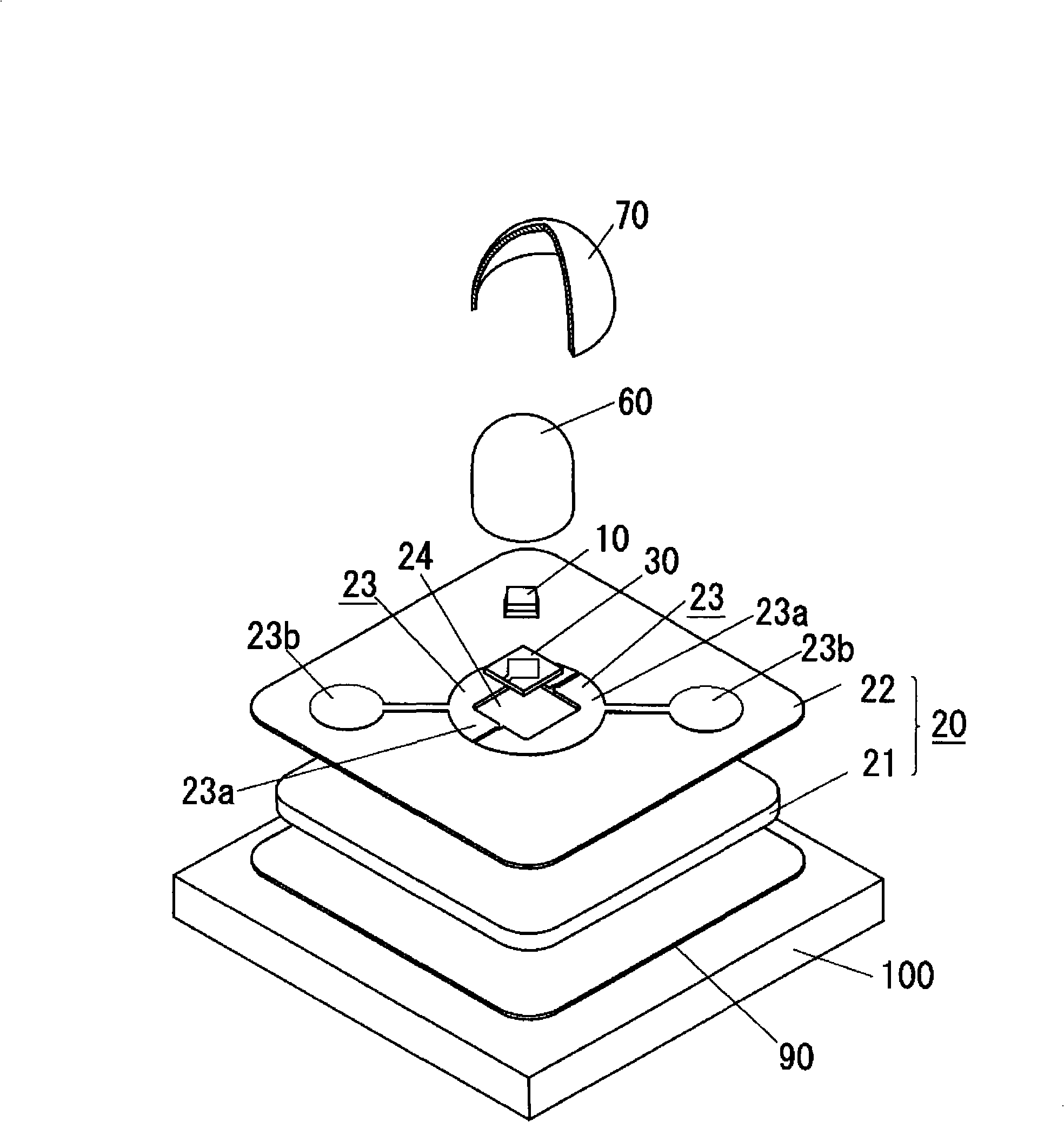

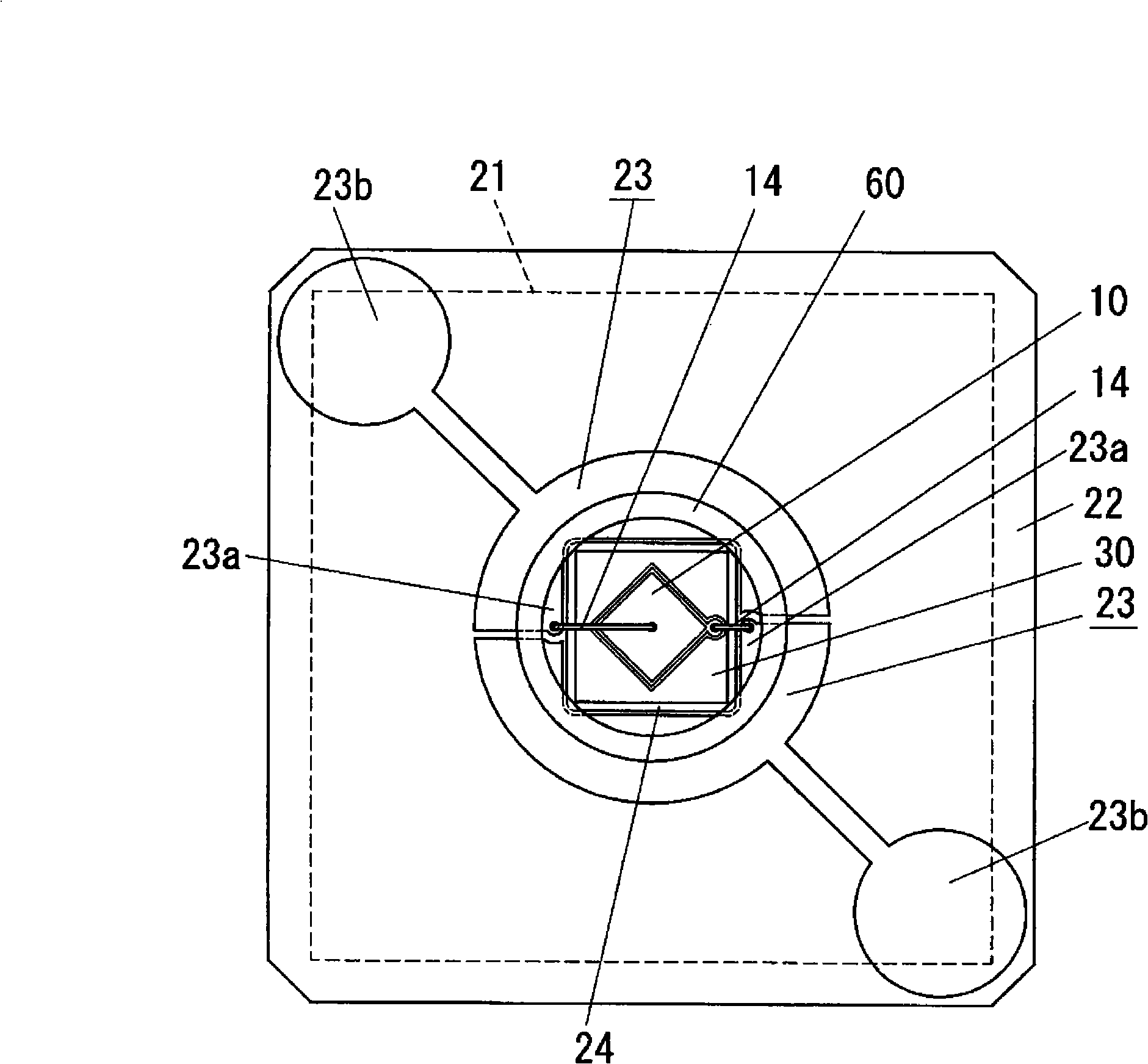

[0057] Such as Figure 1 to Figure 3 As shown, the light-emitting device 1 of this embodiment includes: LED chips 10; a mounting substrate 20 for mounting the LED chips 10; a packaging component 50, which has elasticity and is made of packaging resin materials, and is used to package the LED chips 10 and The bonding wire 14 connected to the LED chip 10 ; the lens 60 made of a transparent resin material; The color conversion component 70 is made of transparent material and fluorescent material; wherein, the fluorescent material is excited by the light emitted from the LED chip 10 to emit light of a color different from that emitted by the LED chip 10 . The lens 60 has a recess 40 facing the surface of the mounting substrate 20 ; and, by disposing the package component 50 in the recess 40 , the lens 60 is fixed on the mounting substrate 20 . The color conversion member 70 is arranged to cover the lens 60 such that an air layer 80 is formed between the color conversion member 70...

no. 2 example

[0087] The light emitting device 1 of the present embodiment consists of Figure 10 shown, and its basic components are almost identical to those of the first embodiment. Therefore, the same reference numerals are used to designate the same components, and related explanations will not be repeated.

[0088] In this embodiment, the inner diameter of the circular hole 26a formed in the central portion of the resist layer 26 is set to be slightly smaller than the maximum inner diameter of the color conversion member 70, and the color conversion member 70 is mounted on the mounting substrate through an adhesive 75 20, wherein the entire circumference of the color conversion member 70 is bonded to the periphery of the circular hole 26a.

[0089] The manufacturing method of the light emitting device 1 of this embodiment includes the following steps. First, the LED chip 10 is mounted on the mounting substrate 20, and the LED chip 10 is connected to the mounting substrate 20 through...

no. 3 example

[0092] The light emitting device 1 of the present embodiment consists of Figure 12 shown, and its basic components are almost identical to those of the first embodiment. Therefore, the same reference numerals are used to designate the same components, and related explanations will not be repeated.

[0093] In the present embodiment, the lens 60 is provided with: an injection port 41 for injecting the encapsulating resin material into the recess 40; and a discharge port 42 for discharging excess encapsulating resin material.

[0094] The manufacturing method of the light emitting device 1 in this embodiment includes the following steps. First, the LED chip 10 is mounted on the mounting substrate 20 , and the LED chip is connected to the mounting substrate 20 through the bonding wire 14 . Then, the lens 60 is adhered to the mounting substrate 20 to seat the LED chip 10 and the bonding wire 14 in the concave portion 40 of the lens (step (a)). Next, an uncured encapsulating resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com