Method for preparing 4-hydroxyphenyl hydantoin

A technology of p-hydroxybenzohydantoin and ureidobenzene, which is applied in the field of medicine and chemical industry, can solve the problems of waste of raw materials and energy, increased production waste liquid treatment cost and environmental pollution pressure, low production yield and the like, and achieves product quality and synthesis. The effect of improving yield, improving utilization rate and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

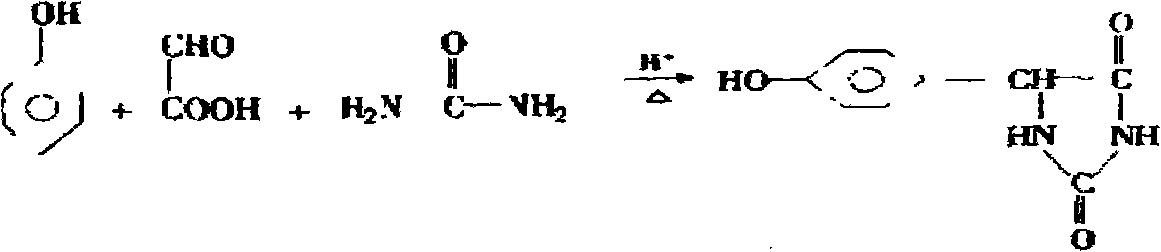

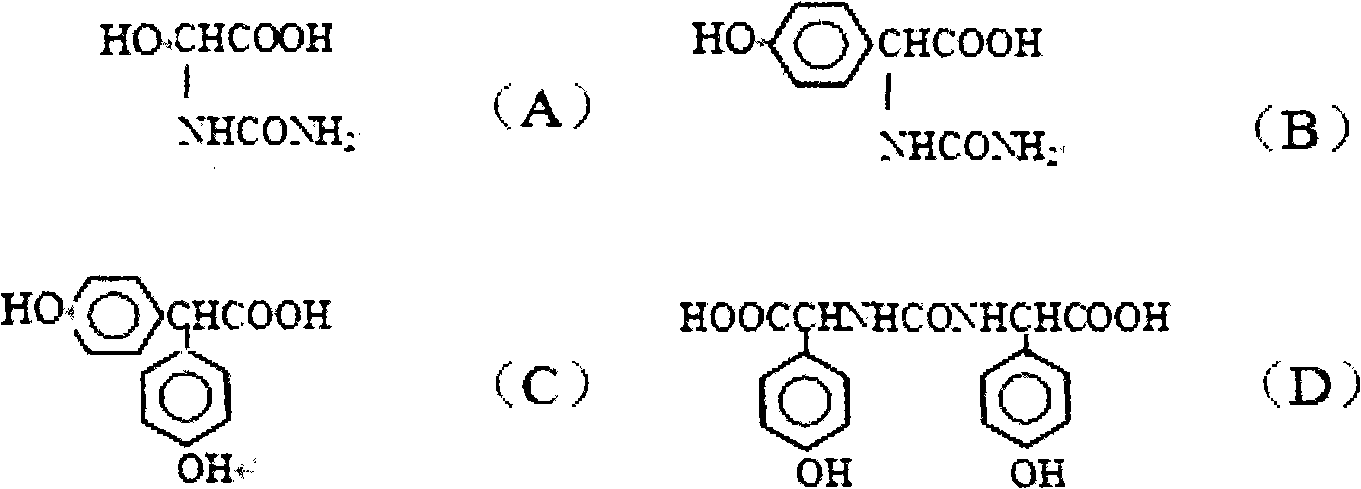

Method used

Image

Examples

Embodiment 1

[0023] Add urea 36g (0.6mol), phenol 40g (0.42mol), sulfamic acid 19.4g (0.10mol), deionized water 200mL and 100mL of 30% hydrochloric acid, start stirring, when the temperature of the feed liquid rises to 50-60°C, start to add 74.0g (0.4mol) of 40% glyoxylic acid solution dropwise, and the dropwise addition is completed in 8-10 hours, then keep warm at 80°C for 4 Hours, the reaction was incubated at 105°C for 2 hours. Then cool to 35°C, vacuum filter the precipitated white p-hydroxyphenylhydantoin crystals, wash with hot water at 40-50°C until the crystals are not easy to stick, soak in methanol, and weigh 48.4g after drying. The content is 99.6% as determined by liquid chromatography. The yield of p-hydroxyphenylhydantoin was 62.7%.

[0024] The mother liquor is neutralized to PH4-6 with concentrated ammonia water, and precipitates containing p-hydroxyphenylglycine, p-hydroxyphenylhydantoin and by-products are precipitated, the solution is cooled to 10-15°C to complete the ...

Embodiment 2

[0026]Add urea 36g (0.6mol), phenol 40g (0.42mol), sulfamic acid 19.4g (0.20mol), deionized water 200mL and 100mL of 30% hydrochloric acid, start stirring, when the temperature of the feed liquid rises to 50-60°C, start to add 74.0g (0.4mol) of 40% glyoxylic acid solution dropwise, the dropwise addition is completed in 8-10 hours, and then keep warm at 80°C for 4 Hours, the reaction was incubated at 105°C for 2 hours. Then cool the reaction liquid to 35°C, vacuum filter the precipitated white p-hydroxyphenylhydantoin crystals, wash with hot water at 40-50°C until the crystals are not easy to stick, soak in methanol, and weigh 44.4g after drying, and determine the content by liquid chromatography 99.5%, and the yield of p-hydroxyphenylhydantoin is 57.5%.

[0027] The mother liquor is neutralized to PH4-6 with concentrated ammonia water, and precipitates containing p-hydroxyphenylglycine, p-hydroxyphenylhydantoin and by-products are precipitated, the solution is cooled to 10-15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com