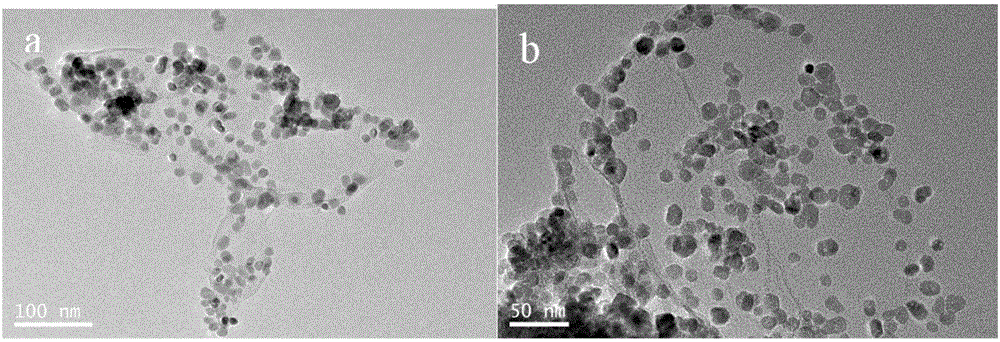

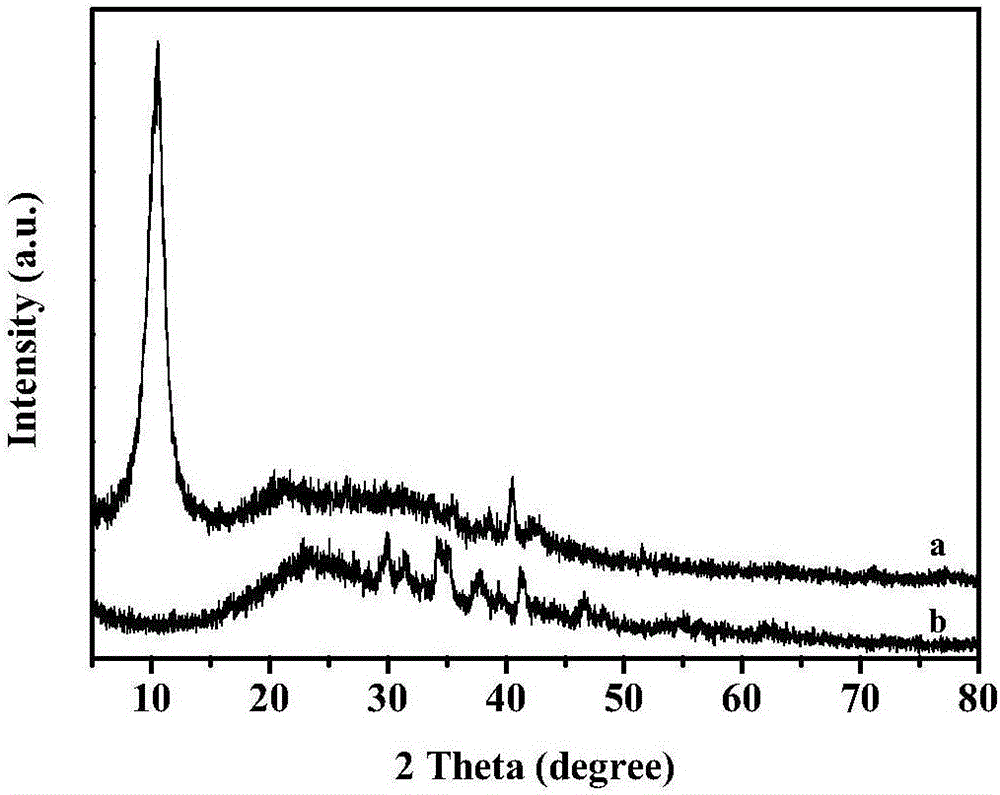

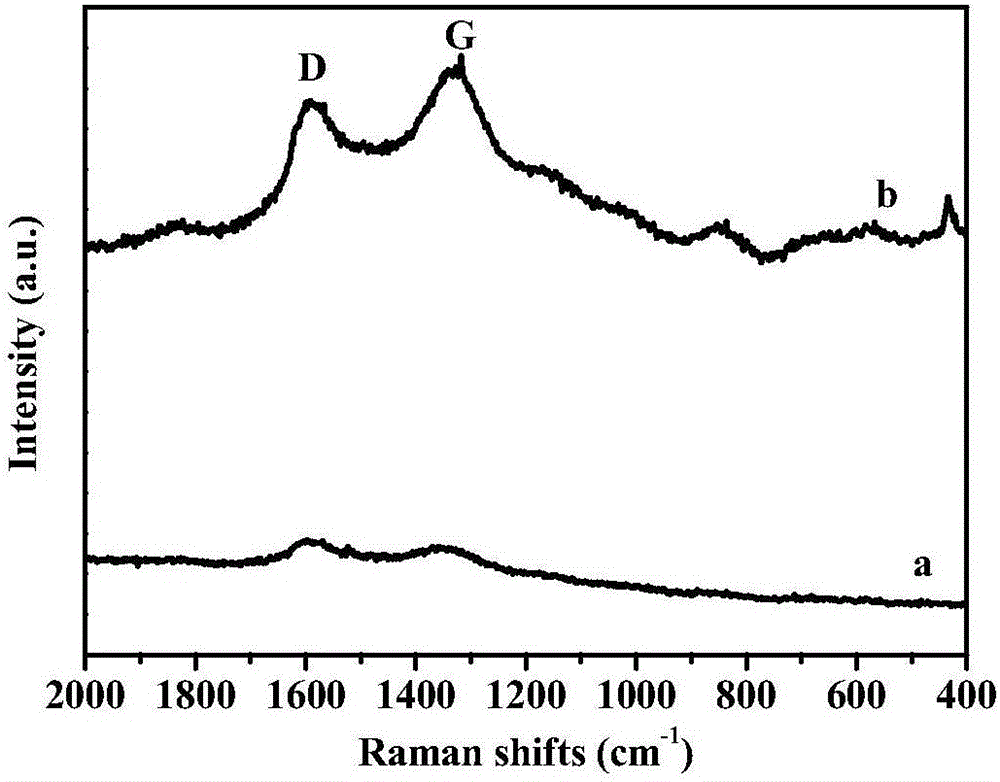

Preparation method for graphene/nano-silver composite antibacterial material

A composite antibacterial and graphene technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as toxicity, environmental and human health risks, and achieve mild reaction conditions and simple preparation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) 2gNaNO 3 Add to a 500mL four-necked flask, add 100mL of 98% concentrated sulfuric acid, and cool in an ice bath. When the temperature of the reaction system is lower than 5°C, add 5g of dry graphite powder under stirring. After mixing evenly, slowly add 10g of graphite powder under vigorous stirring. Potassium permanganate, during the feeding process, control the temperature of the reaction mixture to not exceed 20°C. After the addition, raise the temperature of the reaction liquid to 35°C, and react for 100 minutes. After the reaction, raise the temperature of the reaction solution to 98°C, slowly add 200mL of distilled water dropwise under vigorous stirring, after the addition, control the temperature of the reaction solution at about 98°C, continue to stir for 10min, then add 600mL of deionized water to terminate the reaction ; At the same time, add 30mL30% hydrogen peroxide to remove unreacted potassium permanganate, at this moment the solution turns from browni...

Embodiment 2

[0026] (1) 4gNaNO 3 Add to a 500mL four-neck flask, add 150mL of 98% concentrated sulfuric acid, and cool in an ice bath. When the temperature of the reaction system is lower than 5°C, add 5g of dry graphite powder under stirring. After mixing evenly, slowly add 20g of graphite powder under vigorous stirring. Potassium permanganate, during the feeding process, control the temperature of the reaction mixture to not exceed 20°C. After the addition, raise the temperature of the reaction liquid to 32°C, and react for 180 minutes. After the reaction, raise the temperature of the reaction solution to 98°C, and slowly add 250mL of distilled water dropwise under vigorous stirring. After the addition, control the temperature of the reaction solution at about 98°C, continue to stir for 20min, and then add 800mL of deionized water to terminate the reaction ; At the same time, add 50mL30% hydrogen peroxide to remove unreacted potassium permanganate, at this time the solution turns from br...

Embodiment 3

[0031] (1) 3gNaNO 3Add to a 500mL four-necked flask, add 120mL of 98% concentrated sulfuric acid, and cool in an ice bath. When the temperature of the reaction system is lower than 5°C, add 5g of dry graphite powder under stirring. After mixing evenly, slowly add 15g of graphite powder under vigorous stirring. Potassium permanganate, during the feeding process, control the temperature of the reaction mixture to not exceed 20°C. After the addition, raise the temperature of the reaction liquid to 38°C, and react for 120 minutes. After the reaction, raise the temperature of the reaction solution to 98°C, and slowly add 220mL of distilled water dropwise under vigorous stirring. After the addition, control the temperature of the reaction solution at about 98°C, continue stirring for 15min, and then add 700mL of deionized water to terminate the reaction ; At the same time, add 40mL30% hydrogen peroxide to remove unreacted potassium permanganate, at this time the solution turns from ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com