Multi-effect membrane distillation device with efficient internal heat reclamation function and method

A multi-effect membrane distillation and heat recovery technology, which is applied to chemical instruments and methods, distillation separation, separation methods, etc., can solve problems such as unspecified experimental data, and achieve the effects of simple operation, compact structure, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Feed liquid: a sodium chloride (NaCl) aqueous solution with a salt concentration of 3% by weight, which is equivalent to the salt concentration in the original seawater from seawater desalination.

[0055] Feed liquid feed temperature: 25~30℃

[0056] Heat source: hot water with a temperature of 98-100°C

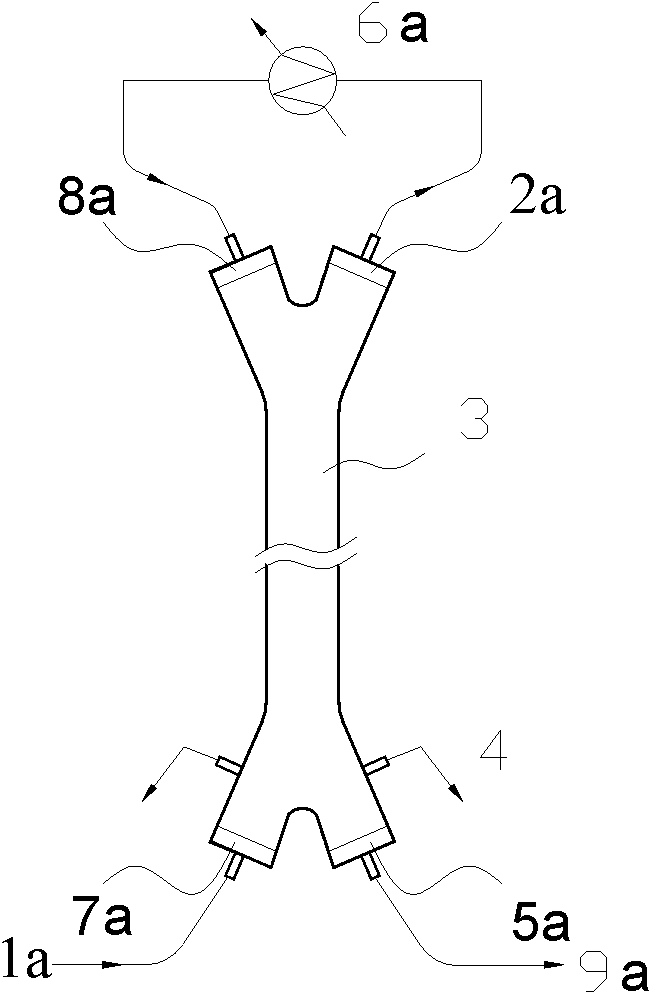

[0057] Mode of operation: use figure 2 The cold feed method shown for the multi-effect membrane distillation process

[0058] Experimental results:

[0059] The water flux of the multi-effect hollow fiber membrane module is: 6.28L / (m 2 h).

[0060] The water making ratio is: 12.5.

[0061] The conductivity of distilled water is: 3.2μs / cm.

Embodiment 2

[0063] Feed liquid: a sodium chloride (NaCl) aqueous solution with a salt concentration of 6% by weight, which is equivalent to the salt concentration in the by-product concentrated brine produced in the traditional seawater desalination process.

[0064] Feed liquid feed temperature: 25 ~ 30 ℃.

[0065] Heat source: hot water with a temperature of 98-100°C.

[0066] Mode of operation: use figure 2 The cold-feed approach shown is for a multi-effect membrane distillation process.

[0067] Experimental results:

[0068] The water flux of the multi-effect hollow fiber membrane module is: 5.88L / (m 2 h).

[0069] The water making ratio is: 10.4.

[0070] The conductivity of distilled water is: 7.2μs / cm.

Embodiment 3

[0072] Feed liquid: the weight percent concentration of salt is 15% sodium chloride (NaCl) aqueous solution.

[0073] Feed liquid feed temperature: 95 ~ 100 ℃.

[0074] Cold source: ground water.

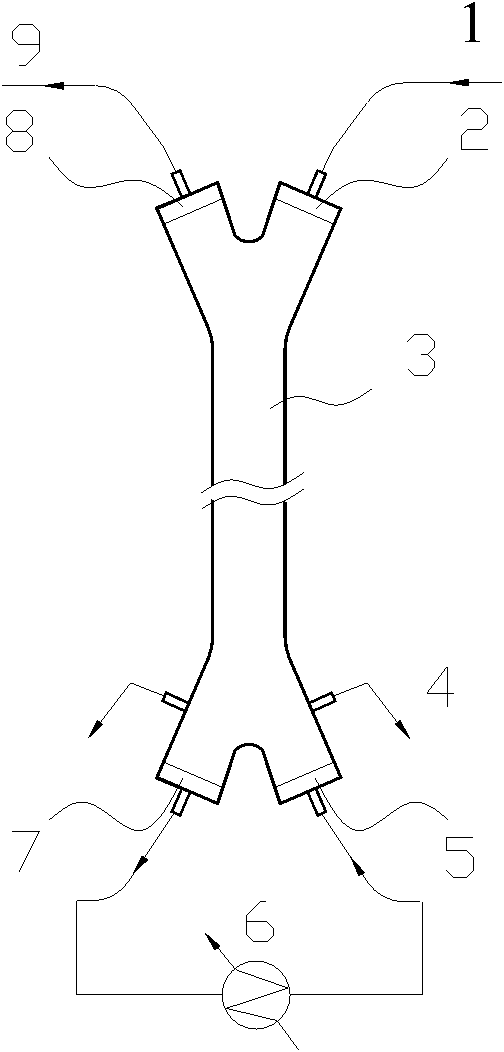

[0075] Mode of operation: use figure 1 The hot feed mode shown carries out the multi-effect membrane distillation process.

[0076] Experimental results:

[0077] The water flux of the multi-effect hollow fiber membrane module is: 4.20L / (m 2 h)

[0078] The water making ratio is: 7.6.

[0079] The conductivity of distilled water is: 10.2μs / cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com