A kind of water-based antibacterial coating and preparation method thereof

A water-based, water-based emulsion technology, applied in antifouling/underwater coatings, coatings, paints containing biocide, etc., can solve the problems of weakened antibacterial ability, low effective concentration, and inability to achieve long-term antibacterial ability. Achieve the effects of excellent adhesion and flexibility, good color development, and excellent heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

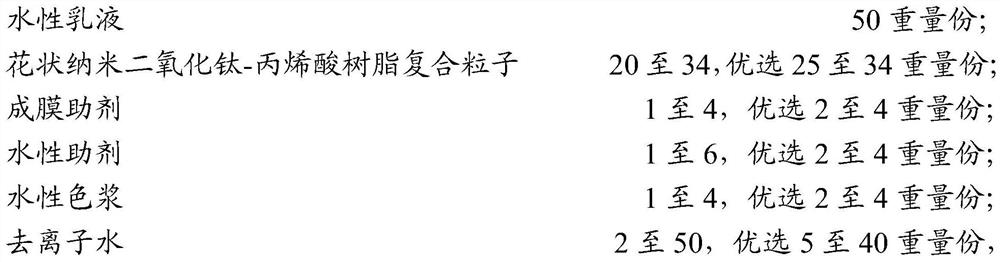

Method used

Image

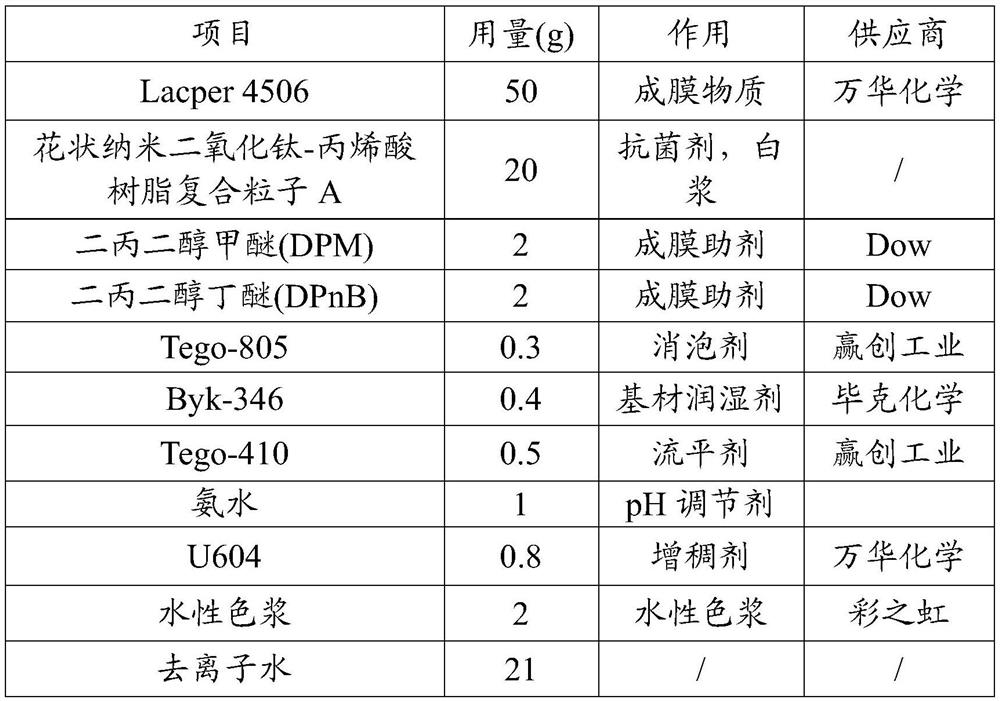

Examples

preparation Embodiment 1

[0060] Preparation of flower-like nano titanium dioxide modified by silane

[0061] Disperse 75g of flower-shaped nano-titanium dioxide in a mixed solution of 135g of ethanol and 100g of deionized water, sonicate for 15min, add 0.8g of γ-methacryloxypropyltrimethoxysilane (KH-570) and continue to sonicate for 30min , transfer the obtained suspension to a microwave hydrothermal kettle, microwave hydrothermal heating at 50°C for 30 minutes, so that the silane coupling agent is rapidly hydrolyzed and combined on the surface of the flower-shaped nano-titanium dioxide, and after cooling to room temperature, the suspension is Filter and rinse with deionized water to obtain silane-modified flower-like nano-titanium dioxide.

[0062] Preparation of shell pre-emulsion

[0063] It is obtained by controlling the dropping process in the preparation method of the water-based acrylic polymer emulsion used. Weigh 30g of methyl methacrylate and 18g of butyl acrylate, 4g of acrylic acid, 5g ...

preparation Embodiment 2

[0068] Preparation of Flower-like Nano-TiO2-Acrylic Resin Composite Particles B

[0069] Silane-modified flower-shaped nano-titanium dioxide was prepared according to Preparation Example 1.

[0070] Preparation of shell pre-emulsion

[0071] It is obtained by controlling the dropping process in the preparation method of the water-based acrylic polymer emulsion used. Weigh 30g of methyl methacrylate and 15g of butyl acrylate, 3g of acrylic acid, 2.5g of vinyltrimethoxysilane, 4g of sodium dodecylbenzenesulfonate, 64g of deionized water, stir and pre-emulsify After 60 min, the shell layer pre-emulsion was obtained.

[0072] The initiator that takes by weighing 0.4g is dissolved with 10g deionized water, obtains initiator solution;

[0073] Stir 24.4g of deionized water, 2.6g of sodium dodecylbenzene sulfonate and 60g of silane-modified flower-like nano-titanium dioxide as a core layer pre-emulsion. When the temperature rises to 80°C, drop The time for adding the initiator so...

preparation Embodiment 3

[0075] Preparation of Flower-like Nano-TiO2-Acrylic Resin Composite Particles C

[0076] Silane-modified flower-shaped nano-titanium dioxide was prepared according to Preparation Example 1.

[0077] Preparation of shell pre-emulsion

[0078] It is obtained by controlling the dropping process in the preparation method of the water-based acrylic polymer emulsion used. Weigh 30g of methyl methacrylate and 5g of butyl acrylate, 1.5g of acrylic acid, 1.5g of vinyltrimethoxysilane, 1.5g of sodium dodecylbenzenesulfonate, 50g of deionized water, and stir Pre-emulsified for 60 minutes to obtain a shell pre-emulsion.

[0079] The initiator that takes 0.75 is dissolved with 10g deionized water, obtains initiator solution;

[0080] Stir 22.4g of deionized water, 2.6g of sodium lauryl sulfate and 60g of silane-modified flower-shaped nano-titanium dioxide to make a core layer pre-emulsion. The time for adding the agent solution and 23g of the shell pre-emulsion is 3 hours, and the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com