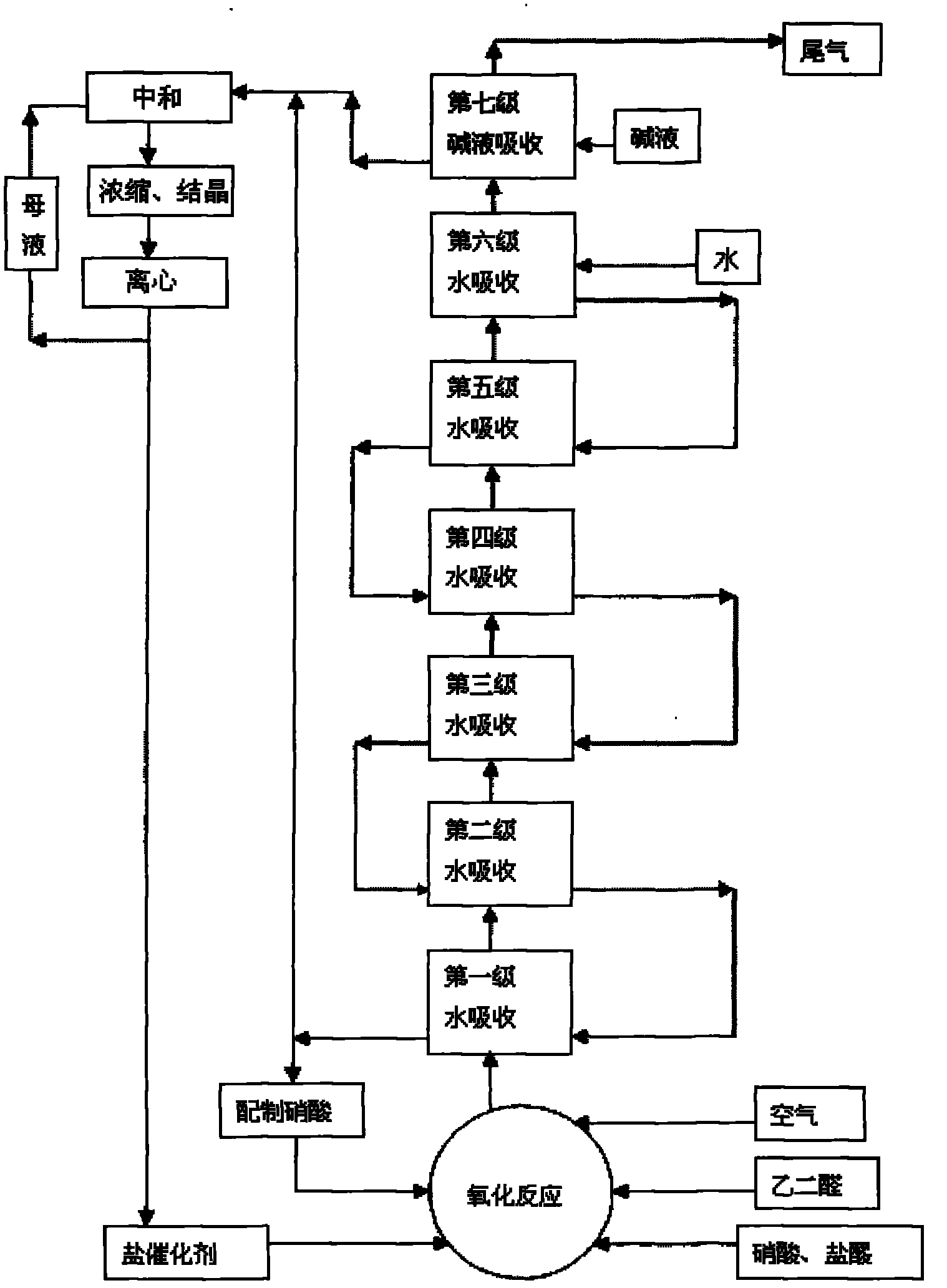

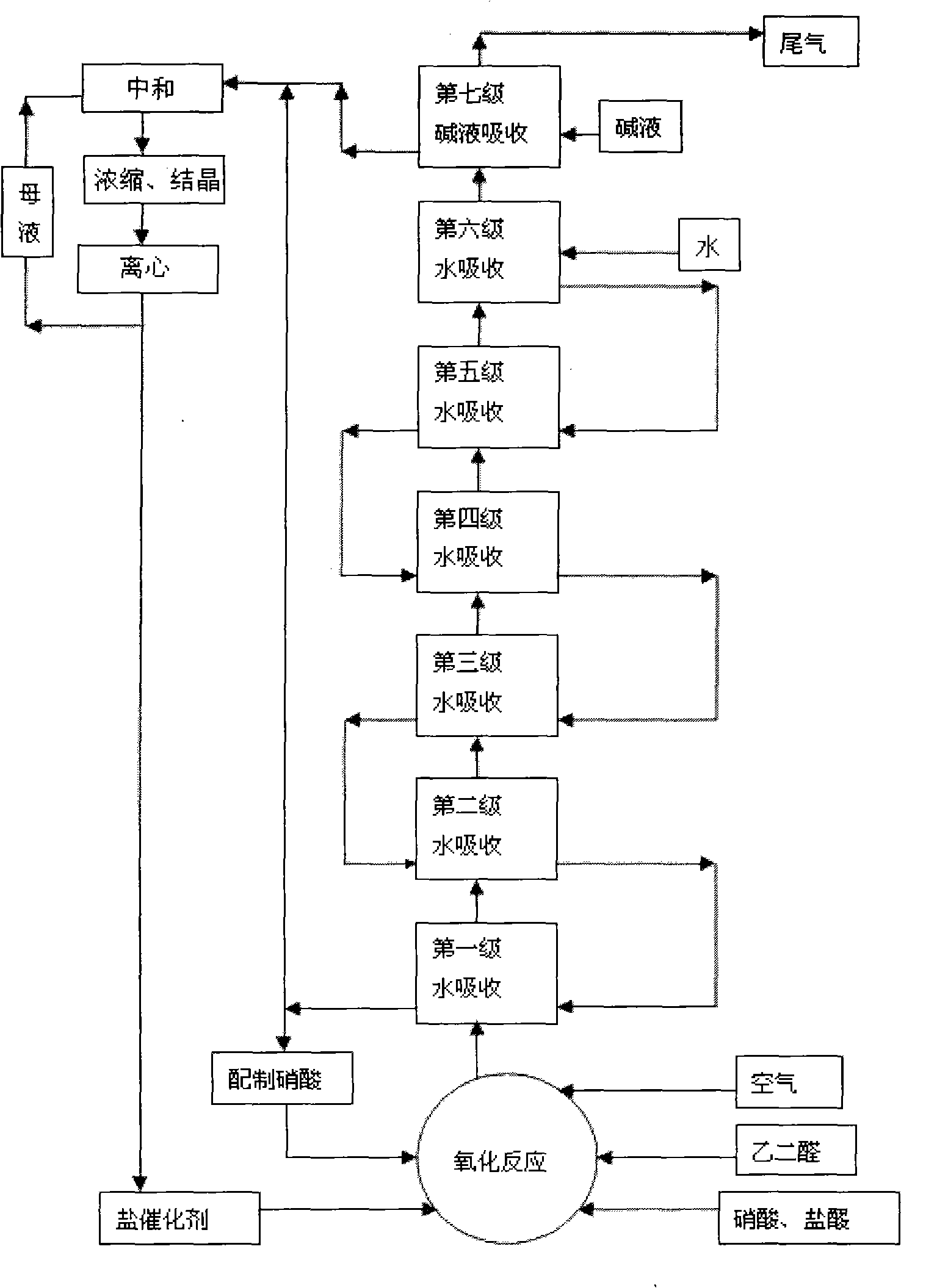

Treatment method and treatment system of tail gas from glyoxylic acid production by nitric acid oxidation of glyoxal

A technology for treating glyoxal, nitric acid and tail gas is applied in the fields of energy saving, consumption reduction and environmental protection, and can solve the problems of high energy consumption, low recovery rate of useful substances, complicated process steps for tail gas treatment, etc. The effect of low maintenance cost and raw material saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

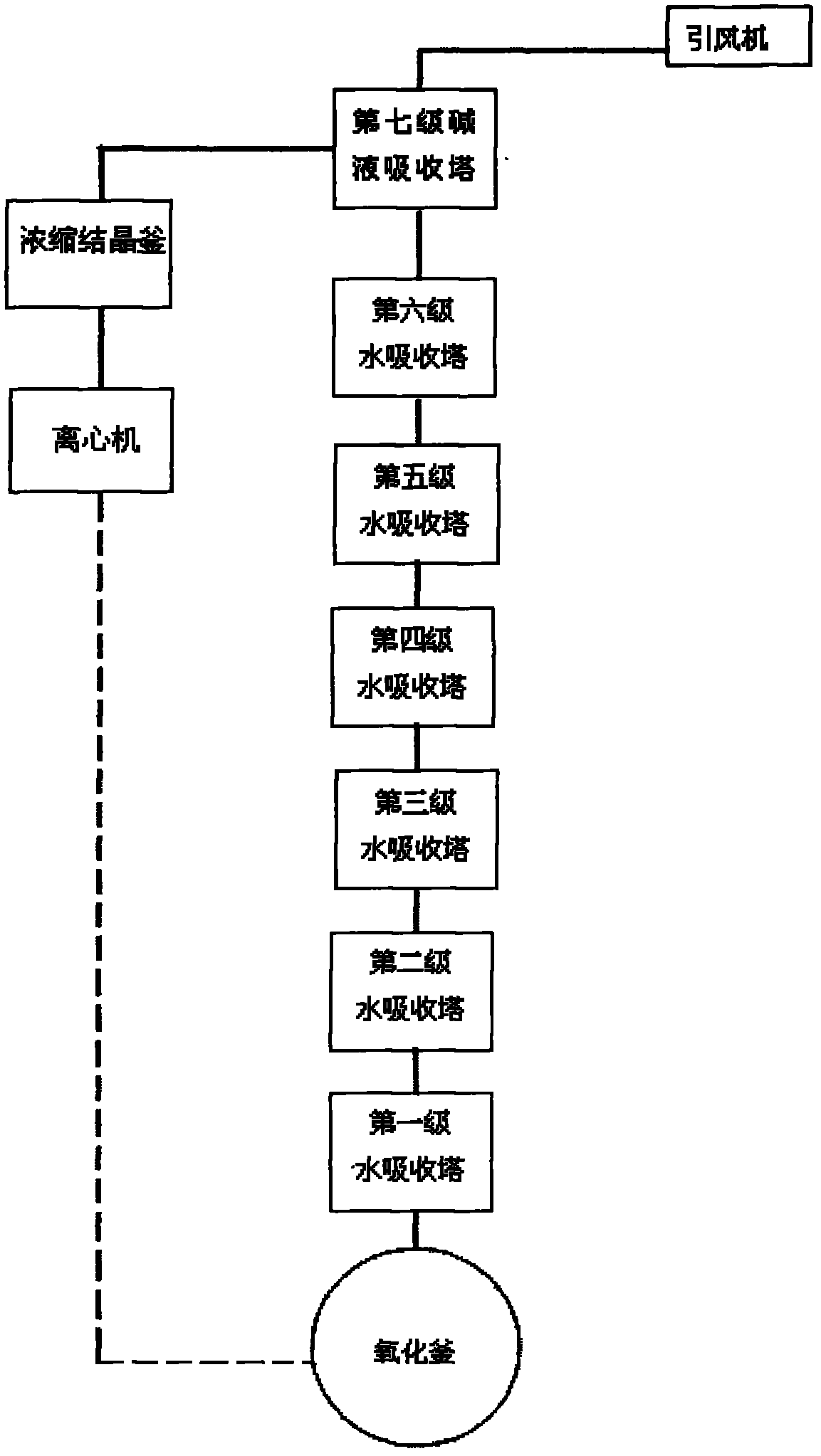

Method used

Image

Examples

Embodiment 1

[0044] The discharge from the oxidation reactor contains NO x and the tail gas of HCl, the induced draft fan at the end of the seventh stage alkali absorption tower (gas flow 9500m 3 / h) Under the action of negative pressure (-0.003MPa) produced, the air (containing 21% O 2 ) after mixing, enter the series first to sixth water absorption towers for water absorption, and remove most of the NO and NO in the tail gas 2 and HCl gas into a mixed acid solution containing nitric acid and a small amount of hydrochloric acid. Then, adjust the mixed acid solution extracted from the first-stage water absorption tower with concentrated nitric acid to make its concentration reach 45% (mass percentage), and then return to the oxidation reactor for circulation reaction. The absorption temperature of the first stage to the sixth stage water absorption tower is controlled at 35°C. The tail gas after the sixth-stage water absorption tower enters the seventh-stage lye absorption tower, and re...

Embodiment 2

[0047] Technological process is identical with example 1, and technological index is adjusted as follows:

[0048] The gas flow rate of induced draft fan is 9000m 3 / h, pressure-0.004MPa in the oxidation reactor still, the mixed acid concentration of the first stage water absorption tower absorption end point is 30% (mass percentage), adjusts its concentration with concentrated nitric acid and reaches 40% (mass percentage) after applying mechanically to the oxidation main reaction. The absorption temperature of the first stage to the sixth stage water absorption tower is 25 ℃, and the seventh stage alkali liquor absorption tower adopts 30% (mass percentage) Na 2 CO 3 The solution is absorbed, the pH value of the lye absorption end point is 10.0-11.0, and the pH value of the neutralization end point is 7.0.

[0049] After the above process is completed, the tail gas is finally discharged from the outlet of the induced draft fan, and the NO in the tail gas x and the total co...

Embodiment 3

[0051] Technological process is identical with example 1, and technological index is adjusted as follows:

[0052] Induced fan gas flow 10000m 3 / h, pressure-0.005MPa in the oxidation reactor still, the mixed acid concentration of the first stage water absorption tower absorption end point is 25% (mass percentage), adjusts its concentration with concentrated nitric acid and reaches 35% (mass percentage) after applying mechanically to the oxidation main reaction. The absorption temperature of the first stage to the sixth stage water absorption tower is 20 ℃, and the seventh stage lye absorption tower adopts 25% (mass percentage) NaOH solution to absorb, and the pH value of the lye absorption end point is 10.5-11.5, medium And the pH of the end point is 7.0.

[0053] After the above process is completed, the tail gas is finally discharged from the outlet of the induced draft fan, and the NO in the tail gas x and the total content of HCl is 185ppm, of which NO x The content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com