Organic electroluminescent component and manufacturing method thereof

An electroluminescence device and electroluminescence technology, which are applied in the manufacturing of organic semiconductor devices, electric solid state devices, semiconductor/solid state devices, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

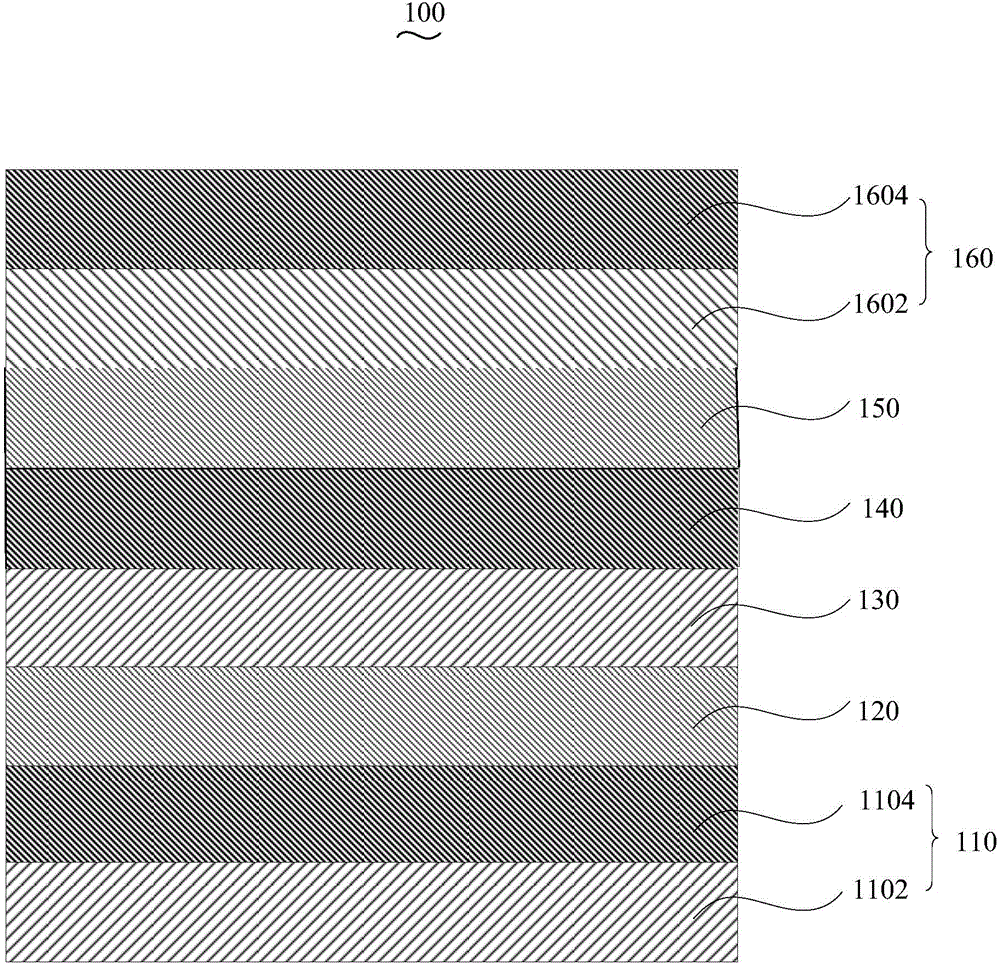

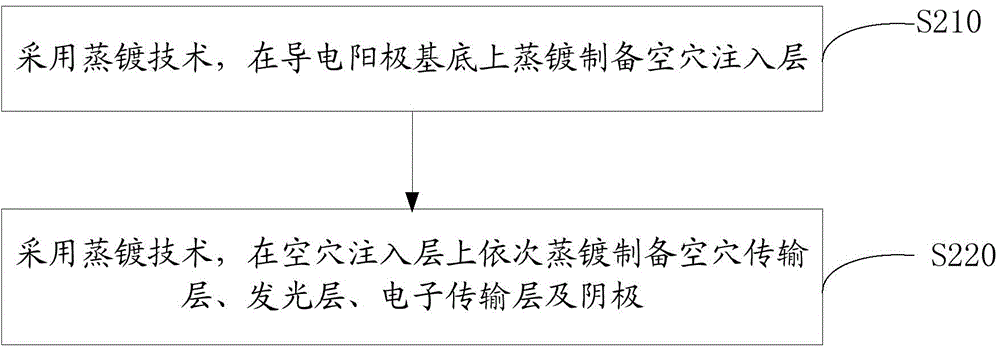

[0040] see figure 2 , the preparation method of the organic electroluminescent device of an embodiment, comprises the following steps:

[0041] S210 , preparing a hole injection layer 120 on the conductive anode substrate 110 by evaporation using an evaporation technique.

[0042] Wherein, the conductive anode substrate 110 includes a transparent substrate 1102 and an anode layer 1104 prepared on the transparent substrate 1102 . Preferably, the transparent substrate 1102 is glass. The material of the anode layer 1104 is indium tin oxide (ITO). The sheet resistance of the anode layer 1104 is 5˜100Ω / sq.

[0043] Preferably, before preparing the hole injection layer by evaporating the anode layer on the surface of the conductive anode substrate, a step of cleaning the conductive anode substrate is also included. The cleaning step is as follows: the conductive anode substrate is ultrasonically cleaned with detergent, deionized water, acetone, ethanol and isopropanol in sequen...

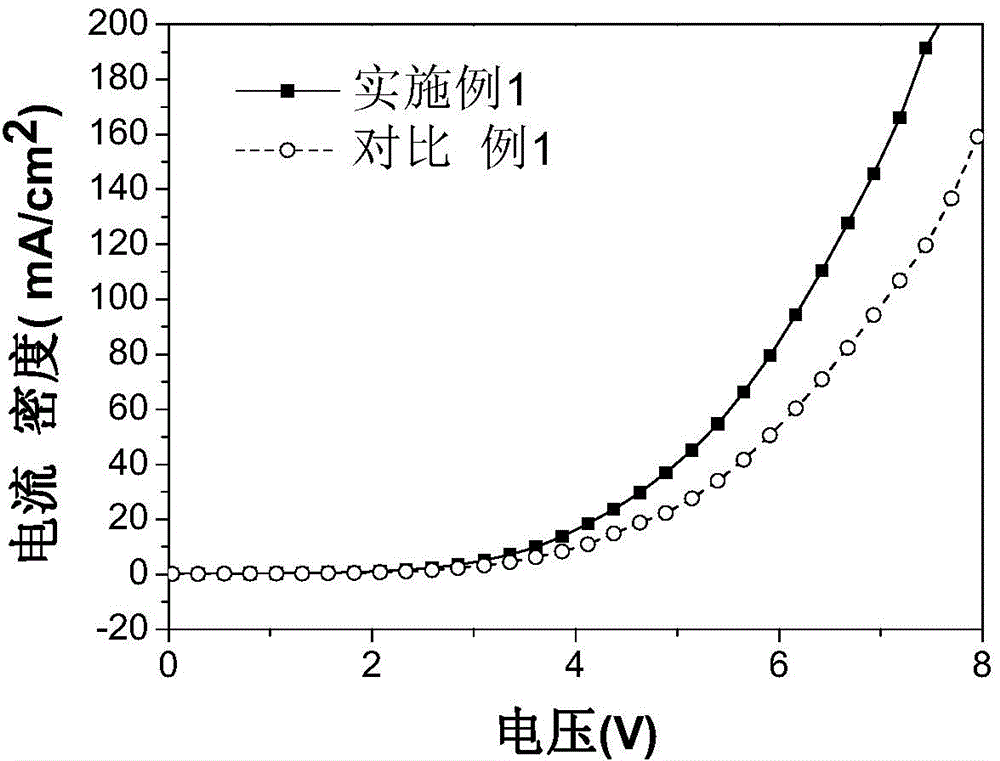

Embodiment 1

[0069] The structure of the organic electroluminescent device prepared in this embodiment is: ITO / FeF 3 / m-MTDATA / TPBi:Ir(ppy) 3 / Bphen / LiF / Ag; where, the slash " / " indicates a layered structure, and the colon ":" indicates doping, the same below.

[0070] The preparation of the organic electroluminescent device of this embodiment is as follows:

[0071] (1) Wash the ITO glass substrate sequentially with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface. The square resistance of the ITO conductive glass is 5Ω / sq.

[0072] (2) In a vacuum of 1×10 -5In the vacuum coating system of Pa, the hole injection layer is prepared on the surface of the conductive anode ITO by using thermal resistance evaporation technology, and the material is iron trifluoride (FeF 3 ), the thickness is 2nm, and the evaporation rate is 0.01nm / s.

[0073] (3) In a vacuum of 1×10 -5 In Pa's vacuum coating system, the hole transport layer is prep...

Embodiment 2

[0082] The structure of the organic electroluminescent device prepared in this example is: ITO / ReCl 3 / NPB / BCzVBi / TPBi / CsF / Al.

[0083] The preparation of the organic electroluminescent device of this embodiment is as follows:

[0084] (1) Wash the ITO glass substrate sequentially with detergent, deionized water, and ultrasonic for 15 minutes to remove organic pollutants on the glass surface. The square resistance of the ITO conductive glass is 100Ω / sq.

[0085] (2) In a vacuum of 1×10 -3 In the vacuum coating system of Pa, the hole injection layer is prepared on the surface of the conductive anode ITO by thermal resistance evaporation technology, and the material is ruthenium trichloride (ReCl 3 ), the thickness is 15nm, and the evaporation rate is 0.5nm / s.

[0086] (3) In a vacuum of 1×10 -3 In the vacuum coating system of Pa, the hole transport layer is prepared on the surface of the hole injection layer by thermal resistance evaporation technology, the material is NPB,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com