Method for extracting osmium from osmium-containing materials

A material, osmium powder technology, applied in the field of extracting osmium from osmium minerals or osmium-containing materials, can solve the problems of slow absorption, slow absorption of sodium hydroxide, reduced osmium yield, etc., and achieves convenient operation, stable product quality, and process. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

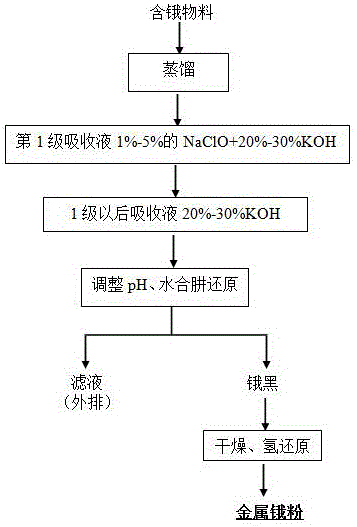

Embodiment 1

[0017] A method for extracting osmium from osmium-containing materials, the specific steps are as follows: add 1kg of osmium sodium salt produced by secondary alloys to 4mol / L hydrochloric acid and distill in a distillation flask, keep the system temperature > 85°C during the distillation process, and contain The liquid-solid ratio of osmium material to hydrochloric acid is 5:1. There are 2 levels of distilled absorption liquid. The first level uses sodium hypochlorite solution with a mass fraction of 1% and potassium hydroxide solution with a mass fraction of 30%. The volume ratio of sodium hypochlorite solution to potassium hydroxide solution is 1:8. The second level uses mass fraction Fractions of 30% potassium hydroxide solution are absorbed. After the absorption was complete, all the absorption liquids were combined, the pH of the solution was adjusted to 8 with hydrochloric acid, osmium black was obtained by reduction with hydrazine hydrate, and the metal osmium powder w...

Embodiment 2

[0019] A method for extracting osmium from osmium-containing materials. The specific steps are as follows: add 500 g of osmium-containing alkali slag to 6mol / L hydrochloric acid and distill in a distillation bottle. During the distillation process, the temperature of the system is kept > 85 ° C, and the osmium-containing material is mixed with hydrochloric acid The liquid-solid ratio is 5:1. There are 6 levels of distilled and absorbed liquids. The first level uses sodium hypochlorite solution with a mass fraction of 2% and potassium hydroxide solution with a mass fraction of 20%. The volume ratio of sodium hypochlorite solution to potassium hydroxide solution is 1:10. Levels 2-6 Absorbed with 30% potassium hydroxide solution by mass fraction. After the absorption is complete, adjust the pH value of the solution to 10 with hydrochloric acid, reduce with hydrazine hydrate to obtain osmium black, dry and reduce with hydrogen to obtain metal osmium powder with a purity greater th...

Embodiment 3

[0021] A method for extracting osmium from osmium-containing materials, the specific steps are as follows: add 3 kg of osmium sodium salt produced by the secondary alloy, add 5mol / L hydrochloric acid and distill in a distillation flask, keep the system temperature > 85°C during the distillation process, wherein The liquid-solid ratio of osmium-containing material to hydrochloric acid is 6:1. There are 4 levels of distillation and absorption liquid. The first level uses hypochlorous acid solution with a mass fraction of 5% and potassium hydroxide solution with a mass fraction of 30%. The volume ratio of hypochlorous acid solution to potassium hydroxide solution is 1:10. Levels 2-4 are absorbed by 30% potassium hydroxide solution. After the absorption is complete, adjust the pH value of the solution to 9 with hydrochloric acid, reduce with hydrazine hydrate to obtain osmium black, and obtain metal osmium powder with a purity greater than 99.95% after drying and hydrogen reductio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com