Method for recycling ruthenium in supported type ruthenium catalyst

A technology of metal catalyst and ruthenium catalyst, which is applied in the recovery field of precious metal catalysts, can solve the problems of high energy consumption and complicated recovery process, and achieve the effect of simplifying the recovery process, reducing costs and reducing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

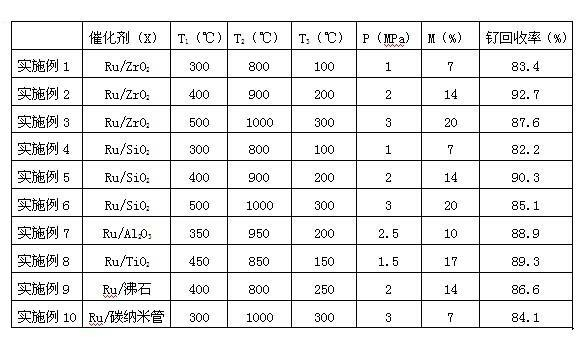

[0034] Examples 1-10: Put 20 g of supported catalysts that do not contain or have removed alkali metals or alkaline earth metals in a closed container, pass through a nitrogen flow to replace the residual gas in the container, heat to T1 ° C, roast for 1.5 hours, and stop nitrogen Flow in, continue to heat up to T2°C, roast for 5 hours, pass in nitrogen gas and slowly cool down to get a black solid, grind the black solid to powder, put it in a closed container, heat up to T3°C, and introduce a pressure of P from the bottom of the container. Mpa ozone oxidation is a black solid in a fluidized state, and the ruthenium tetroxide produced by oxidation is introduced into a dilute hydrochloric acid solution with a concentration of M, and the ruthenium tetroxide gas is absorbed and reduced to a reddish-brown ruthenium trichloride hydrochloric acid solution. The obtained solution was distilled under reduced pressure, and the crystallization was β-RuCl3 xH2O (containing 37.6% ruthenium)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com