Method for separating and recovering Ru from solution containing pt family

A technology for separation, recovery and solution, applied in the direction of improving process efficiency, can solve problems such as cracking, low volatility, and fog scattering, and achieve the effect of preventing decomposition, stable operation, and realizing operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

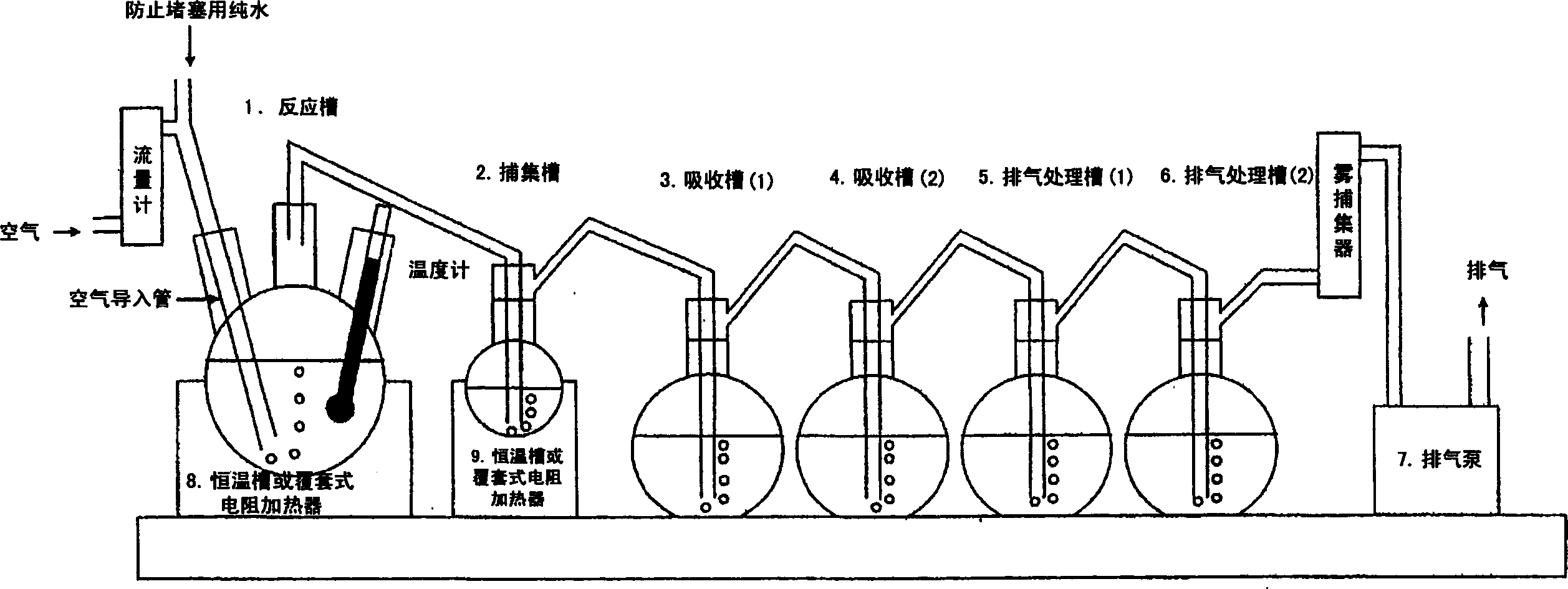

[0046] Embodiments of the present invention will be described below. Example using as figure 1 The distillation apparatus shown. 7 L of an acidic solution of hydrochloric acid containing Ru and a platinum group element adjusted to pH 1 was added to the reaction tank ( 1 ) installed in the mantle heater. Since ruthenium tetroxide was generated when sodium bromate was added to the solution, air was blown into the solution at a rate of 10 L / min while heating the solution to 80°C.

[0047] At this time, in order to prevent clogging, pure water was flowed into the air introduction tube at 0.1 L / hour. The air that contains ruthenium tetroxide vapor is passed into the 3% sodium bromate solution of the catch tank (2) that is heated to 80 ℃, then imports in the absorption tank (3,4) that puts 6N hydrochloric acid solution, will The ruthenium tetroxide vapor is recovered as a ruthenium chloride solution.

[0048] The air after passing through the absorption liquid contains bromine g...

Embodiment 2

[0053] Example 2 will be described below based on the results of the solution composition, solution volume, and Ru distribution ratio of Example 2 in Table 2. In embodiment 2, the concentration of sodium bromate added to the reaction tank solution before the distillation is set to be 221g / L, so that when the 1 equivalent of the oxidation reaction of Ru was 61g / L, the bromic acid in the reaction tank solution after distillation The sodium concentration is 160g / L.

[0054] The concentration of Ru in the reaction tank after distillation was 0.001 g / L or less, and Ru was separated from the reaction tank. Almost all platinum group elements other than Ru remained in the reaction tank, and no platinum group elements other than Ru were contained in the absorption tank. In addition, by providing two stages of absorption tanks, almost all of Ru can be recovered, and Ru can be separated from other platinum group elements.

[0055] Reaction tank before distillation

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com