Reliable fuel cell electrode design

A fuel cell and electrode technology, applied in the direction of fuel cells, battery electrodes, fuel cell components, etc., can solve problems such as corrosion of conductive plates and end plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

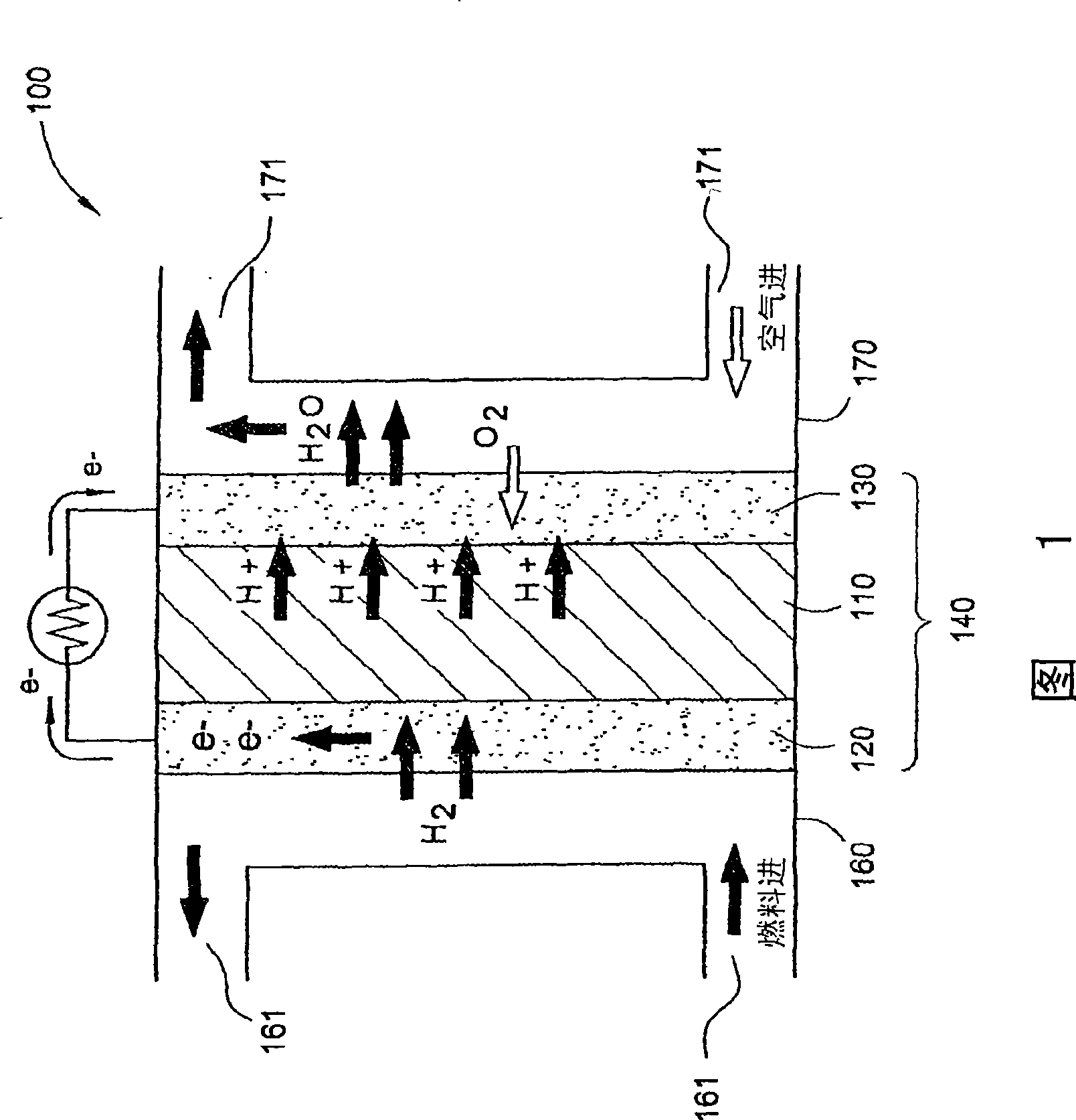

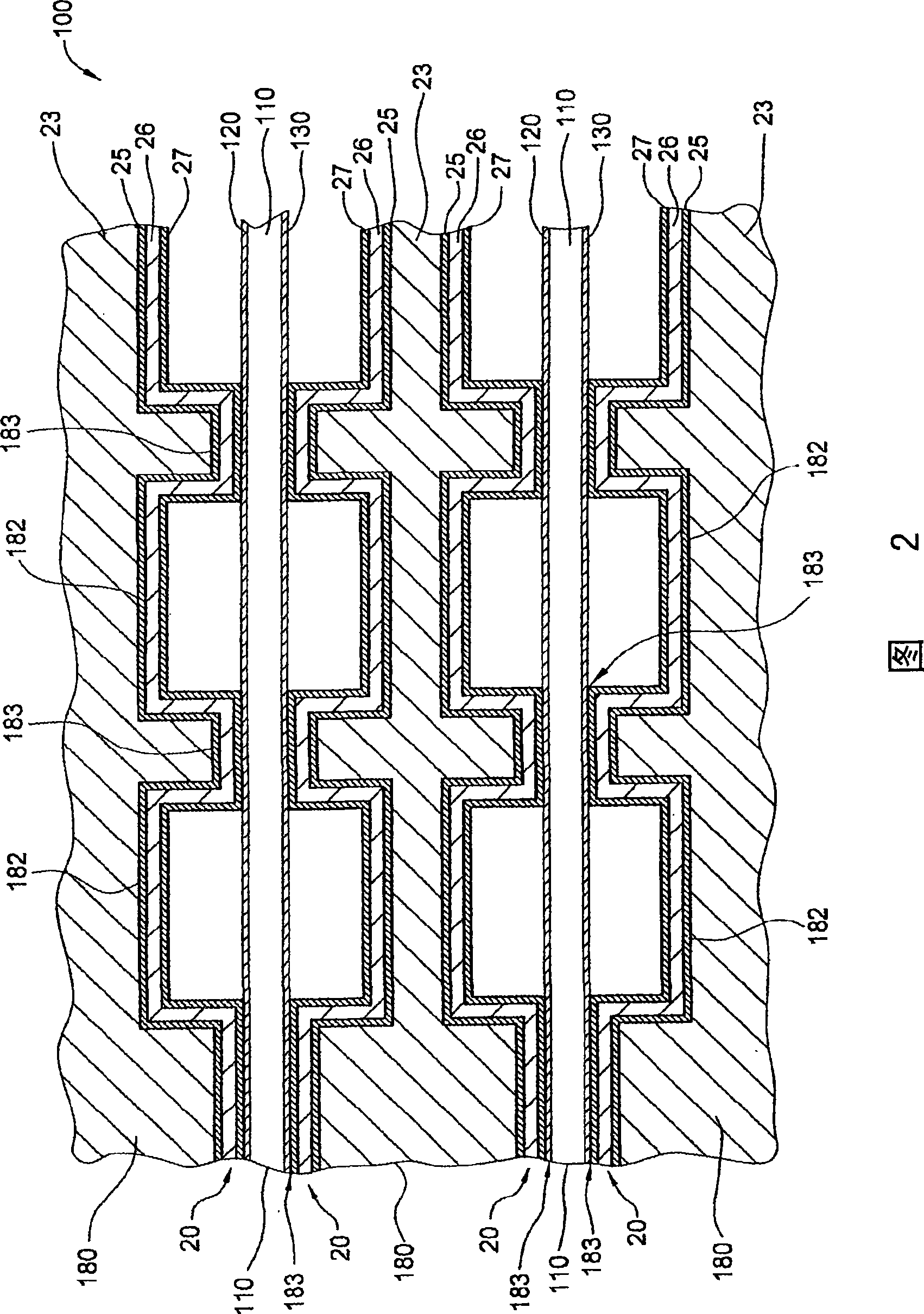

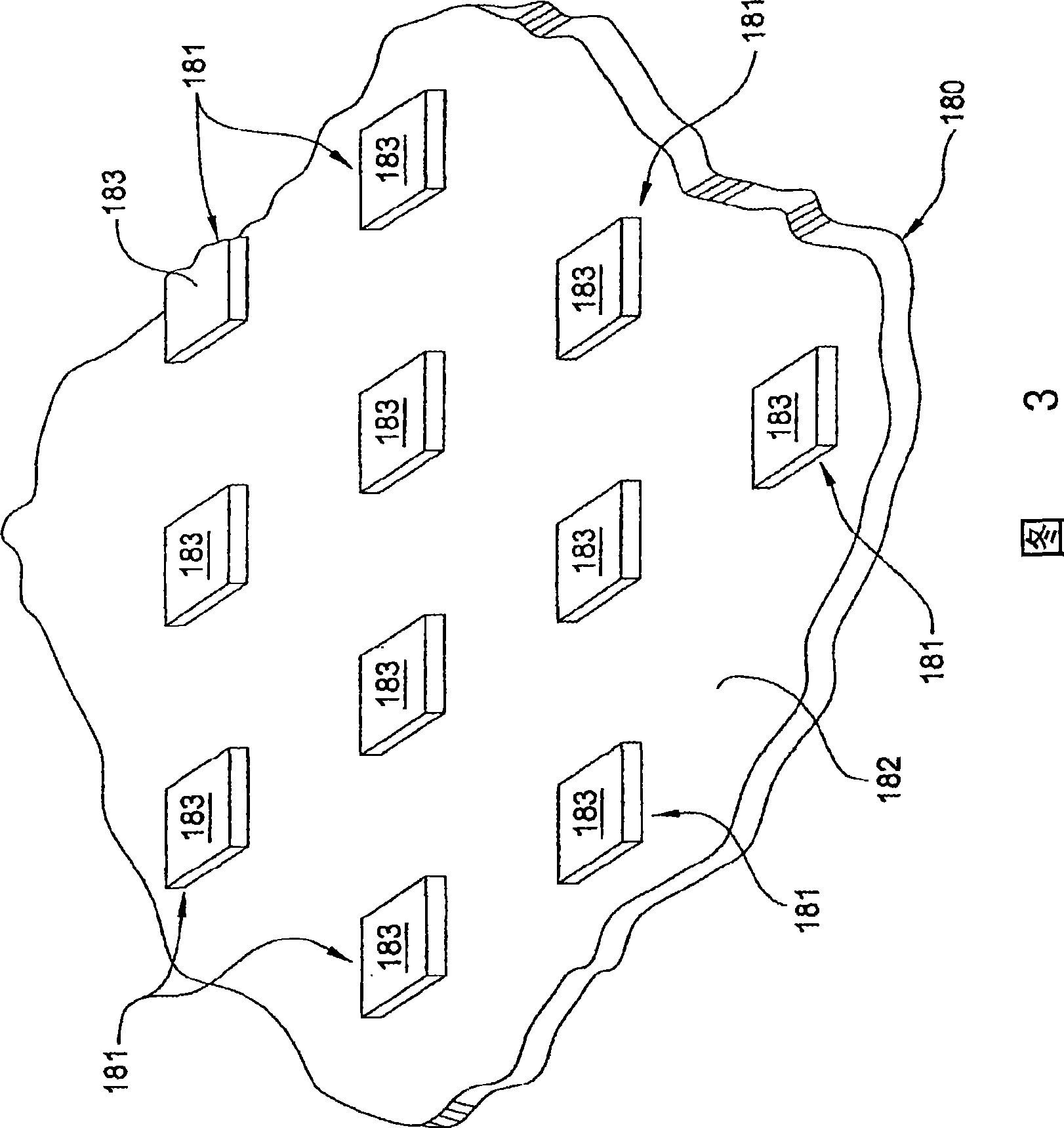

[0026] The present invention generally relates to the invention of fuel cell assemblies and methods of forming various fuel cell assemblies having longer life, lower cost and improved process efficiency. The present invention generally encompasses methods of treating or conditioning the surface of a substrate by depositing one or more layers of material having good substrate adhesion, low electrical resistance (high conductivity), and resistance to chemical attack during fuel cell operation. Better resistance. For example, the substrate can be a fuel cell component, a conductive plate, a separator plate, a bipolar plate, a unipolar plate, or an end plate, among others. But the invention is equally applicable to other kinds of substrates. The substrates of the present invention can be of any shape (eg, circular, square, rectangular, polygonal, etc.) and size. The type of substrate is not limited, and may be any substrate comprising metal, plastic, semiconductor, glass, carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com