Method for producing high-tower nitro-sulfenyl compound fertilizer and production system applying method

A compound fertilizer and production system technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of high residue, easy pulverization, high particle strength of nitrosulfur-based compound fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

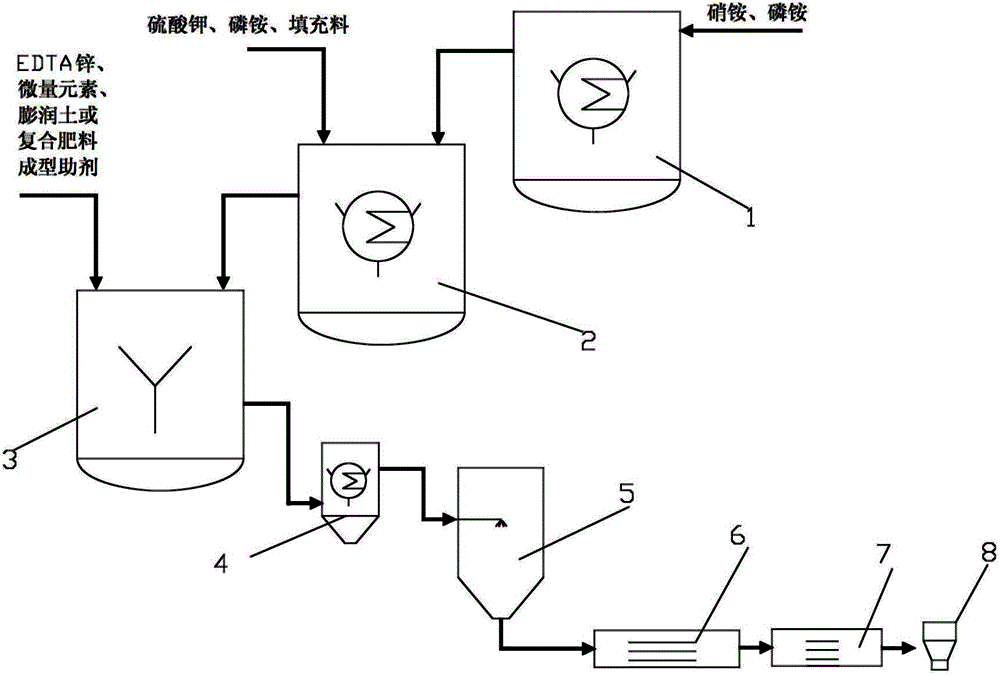

Image

Examples

Embodiment 1

[0041] Example 1: Formula Three Fifteen (15-15-15) Products

[0042] 1. The production method comprises the following steps:

[0043] a) Add 38% (weight) nitrate fertilizer and 20% (weight) monoammonium phosphate (N:P:10-48-0) into melting tank 1 for melting after metering, and overflow to the first level after melting In the mixing tank 2, the melting temperature is 155-165°C;

[0044] b) Add 10.50% (by weight) of monoammonium phosphate (N: P: 10-48-0) and 28% (by weight) of potassium sulfate (KS: 52%) into primary mixing tank 2 after metering, and melt Mixing, the temperature is controlled at 150-165°C, after chelation, the slurry overflows to the secondary mixing tank 3;

[0045] c) Measure 3.0% (weight) of bentonite and 0.5% (weight) of trace elements, enter the secondary mixing tank 3 for chelation, after chelation, it will automatically overflow into the emulsifier 4 for emulsification, and the emulsification temperature is lower than 140°C;

[0046] d) After the slu...

Embodiment 2

[0049] Example 2: Formula Three Sixteen (16-16-16) Products

[0050] 1. The production method comprises the following steps:

[0051]a) 37.50% (weight) of nitrate nitrogen fertilizer and 14.00% (weight) of monoammonium phosphate (N:P:10-48-0) are measured and put into melting tank 1 for melting, and the melting temperature is 155~165°C ;

[0052] b) Add 15.00% (weight) industrial monoammonium phosphate (N:P: 12-61-0) and 31% (weight) potassium sulfate (content 52%), after metering, into primary mixing tank 2, melt and mix , the temperature is controlled at 150-165°C, after chelation, the slurry overflows to the secondary mixing tank 3;

[0053] c) 2% (weight) of bentonite and 0.04% (weight) of forming aids for compound fertilizer granulation, after metering, add to the secondary mixing tank 3, after mixing, overflow into the emulsifier 4, and the emulsification temperature is lower than 140°C ;

[0054] d) After the slurry is emulsified, it enters the prilling tower 5 for ...

Embodiment 3

[0057] Example 3: Formula Three Sixteen (16-16-16) Products

[0058] 1. The production method comprises the following steps:

[0059] a) Add 37.50% (weight) of ammonium nitrate and 14.00% (weight) of monoammonium phosphate (N:P:10-48-0) into the melting tank 1 for melting after metering, and the melting temperature is 155~165°C ;

[0060] b) 15.00% (weight) industrial monoammonium phosphate (N: P: 12-61-0) and 31% (weight) potassium sulfate (content 52%), after metering, add to primary mixing tank 2 for mixing, temperature Controlled at 150-165°C, the mixed slurry overflows to the secondary mixing tank 3;

[0061] c) 2.0% (weight) sodium sulfate, 0.02% (weight) molding aid for compound fertilizer granulation, and 0.3% (weight) EDTA zinc pass through the screw feeder, and after metering, enter the secondary mixing tank 3, After mixing, it overflows into the emulsifier 4, and the emulsification temperature is lower than 140°C;

[0062] d) After the slurry is emulsified, it e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com