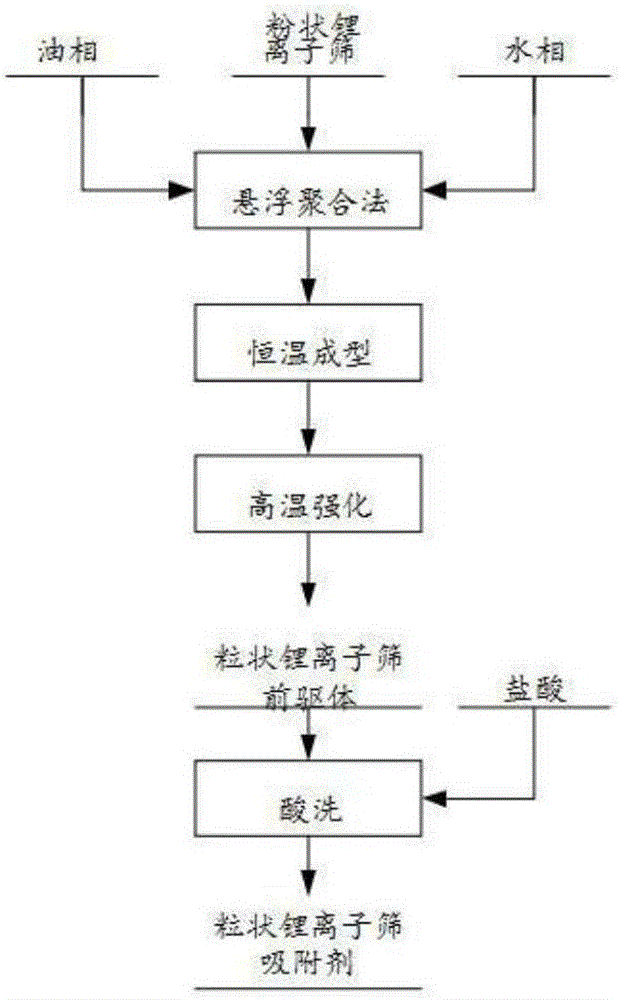

Method for preparing spherical granular lithium ion sieve

A lithium ion, spherical technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of poor appearance and insufficient strength of lithium ion sieves, and achieve good fluidity, high production efficiency, and high particle strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

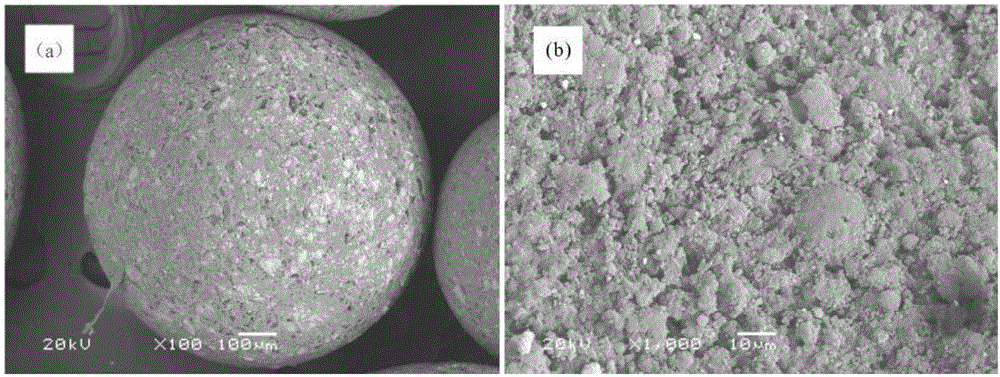

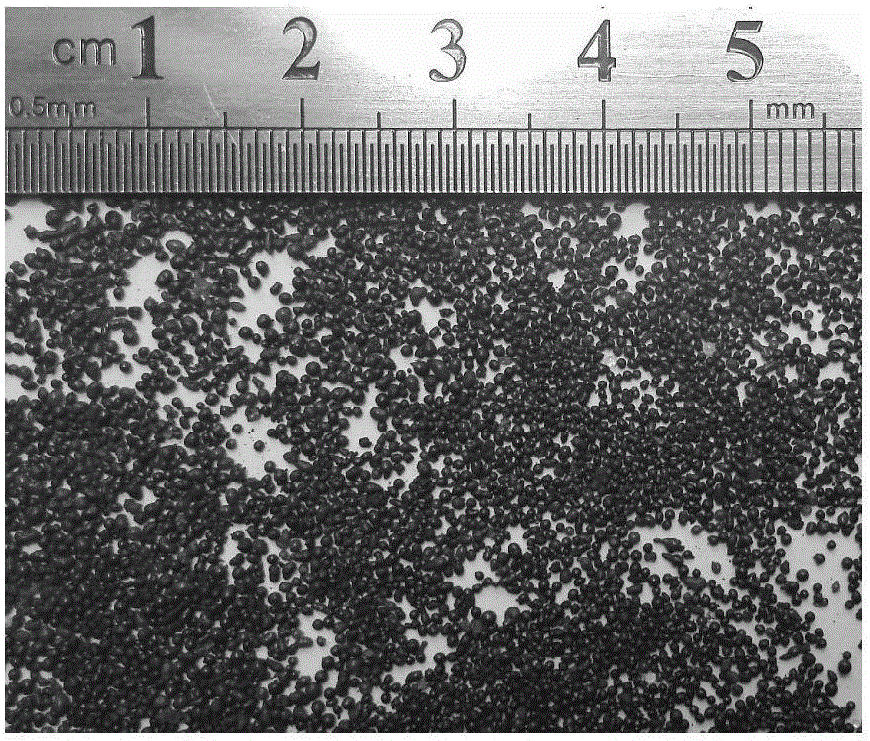

Examples

Embodiment 1

[0052] Weigh 2.5 g of sodium chloride, 0.05 g of polyvinyl alcohol, and 0.25 g of gelatin, and dissolve them in 50 mL of pure water to form an aqueous phase. Measure 1.65 mL of styrene, 5.45 mL of divinylbenzene, 4.77 mL of methyl methacrylate, 10 mL of n-heptane, and 0.3 g of benzoyl peroxide, mix and dissolve to obtain an oil phase. First add the water phase to a three-necked flask with a reflux condenser, and stir until completely dissolved; slowly add 5 g of surface-modified powdered ion sieve (modified by soaking in octadecanoic acid ethanol solution) under stirring, and start heating. After the temperature rises to 60°C, add the oil phase. Slowly raise the temperature to 80°C, and conduct constant temperature polymerization for 3 hours; then raise the temperature to 90°C, and boil the balls for 2 hours. The granulated ion sieve spheres were obtained by filtration, and washed 2-3 times with hot water at 80° C. to remove the granular gelatin. The spheres were then placed...

Embodiment 2

[0057] Weigh NaOH 0.1g, MgCl 2 ·6H 2 Add 0.25g of O to 50ml of deionized water to dissolve, then mix the two solutions; then weigh 0.5g of gelatin and 0.1g of polyvinyl alcohol, add them to the above mixed solution, heat and dissolve to obtain the water phase. Measure 9 mL of styrene, 1 mL of methyl methacrylate, and 0.45 g of benzoyl peroxide, mix and dissolve to obtain an oil phase. First add the water phase into a three-necked flask with a reflux condenser, stir and heat, and when the temperature rises to 60°C, slowly add 6g of surface-modified powdered ion sieve (soaked in octadecanoic acid ethanol solution) under stirring. modification), and then slowly add to the oil phase. Slowly raise the temperature to 80°C, and conduct constant temperature polymerization for 3 hours; then raise the temperature to 90°C, and boil the balls for 1 hour. The granulated ion sieve spheres were obtained by filtration, and washed 2-3 times with hot water at 80° C. to remove the granular ge...

Embodiment 3

[0060] Weigh 3 g of sodium chloride, 0.2 g of polyvinyl alcohol, and 0.5 g of gelatin, and dissolve them in 100 mL of pure water to form an aqueous phase. Measure 10 mL of styrene and 0.45 g of benzoyl peroxide, mix and dissolve to obtain an oil phase. First add the water phase into a three-necked flask with a reflux condenser, stir and heat, and when the temperature rises to 70°C, slowly add 6g of surface-modified powdered ion sieve (soaked in octadecanoic acid ethanol solution) under stirring. modification), and then slowly add to the oil phase. Slowly raise the temperature to 80°C, and conduct constant temperature polymerization for 3 hours; then raise the temperature to 90°C, and boil the balls for 1 hour. The granulated ion sieve spheres were obtained by filtration, and washed 2-3 times with hot water at 80° C. to remove the granular gelatin. Then the particles were dried at 60°C to obtain a spherical granular ion sieve precursor, and after acid washing, a spherical gra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com