Preparation method, product and applications thereof of acetate deep deiodination adsorbent

An adsorbent and acetic acid technology, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, and other chemical processes, can solve the problems of violent molecular thermal movement, different sizes, and poor deiodination effect, etc., to achieve The effect of high particle strength, high silver loading, and high degree of crystallization

Inactive Publication Date: 2010-08-25

SHANGHAI FUXU MOLECULAR SIEVE

View PDF13 Cites 17 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, due to the single pore structure of the zeolite used in the above-mentioned silver-loaded molecular sieve deiodination adsorbent, the iodide removal effect of the molecular size in the acetic acid is different, and the composition is complex.

The reason is that the intracrystalline pore diffusion resistance of large-pore zeolite is small, which is conducive to the removal of large-sized organic iodine molecules through physical adsorption, but for the small-sized inorganic molecular iodine and elemental iodine, the molecular thermal motion is violent, and large Decreased adsorption capacity of pore zeolite

In medium pore zeolites, the organic iodide with larger molecular size is hindered in the diffusion in the pores, and the deiodination effect is poor, and it is easily affected by the fluctuation of the iodine content concentration in the raw material acetic acid, the space velocity of the adsorbent bed, and the operating temperature. The impact of process conditions such as changes, the deiodination effect changes greatly, making the total iodine content of the deiodoacetic acid product cannot be guaranteed to be lower than 5x10 -9 , sometimes even exceeding 10x10 -9

If this unstable product acetic acid is used to synthesize vinyl acetate, it will chronically poison the precious metal catalyst used, shorten its service life, and cause serious losses.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

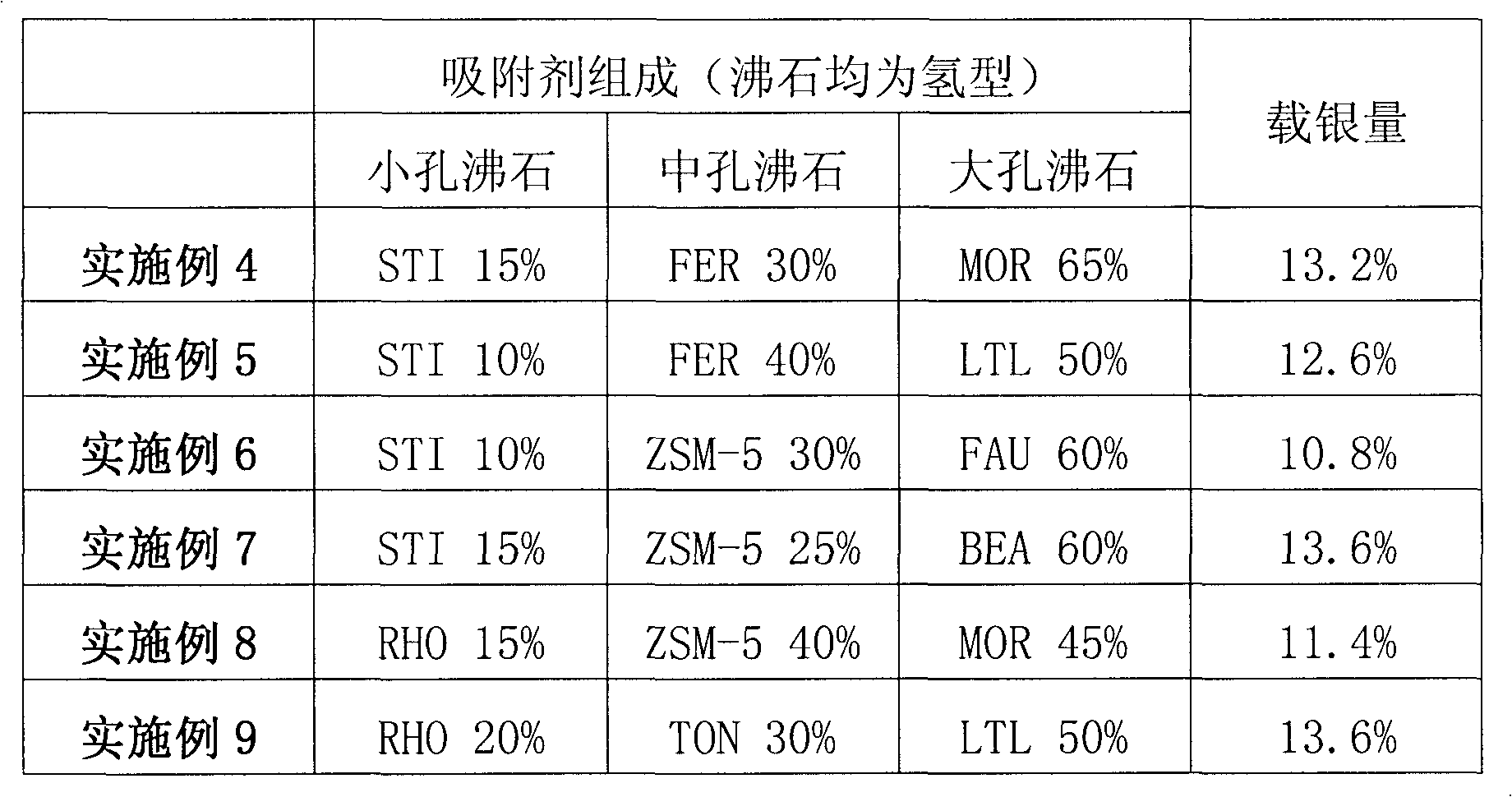

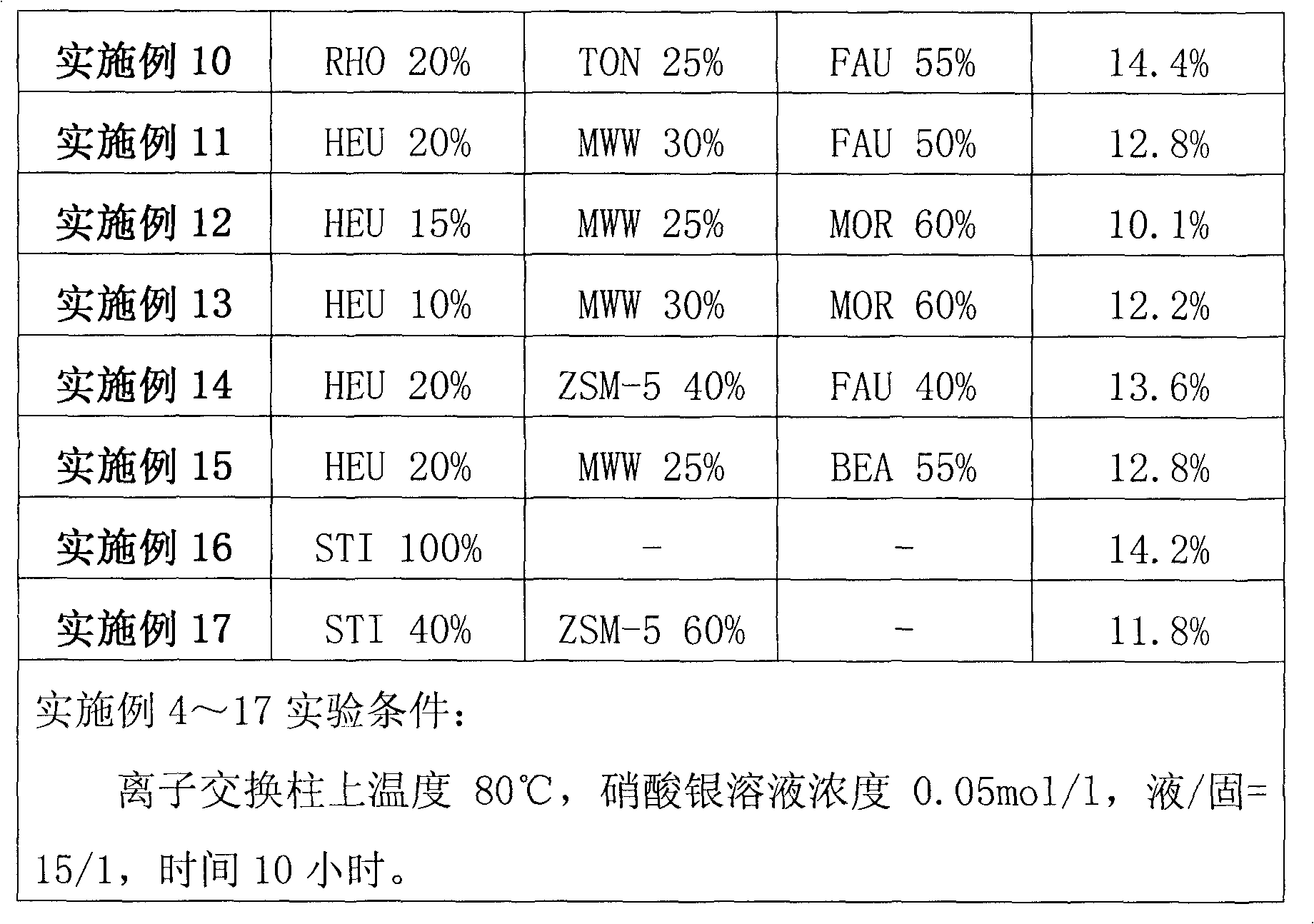

The invention relates to preparation method, product and applications thereof of an acetate deep deiodination adsorbent. The method comprises the following steps of: mixing small-pore, medium-pore and large-pore zeolite molecular sieves with different structures; forming by using an adhesive; generating chemical bonds by hydrothermal strengthening treatment; removing sodium and loading silver by ion exchange to prepare the product. The adsorbent is prepared from the following components in percentage by weight: 10-30% of small-pore zeolite, 20-50% of medium-pore zeolite and 20-70% of large-pore zeolite, and the adhesive accounts for 10-30% of the total weight of the adsorbent. The invention has the advantage that the adsorbent has strong adsorption capability on organic iodide, inorganic iodide and molecular iodine with different sizes in the strong acid medium, the total iodine content in the deep deiodination product is less than 5*10<-9>, and the adsorbent is suitable for being used as raw materials which are used for synthesizing vinyl acetate.

Description

Technical field The invention belongs to the field of chemical engineering technology, and specifically relates to a preparation method of a deeply deiodinated zeolite molecular sieve adsorbent for removing iodide in the process of carbonylation synthesis of carboxylic acid or carboxylic anhydride products, as well as its products and uses. Background technique Since iodide is used as a catalytic promoter in the process of carbonylation to synthesize carboxylic acid or carboxylic anhydride, iodide or its derivatives are inevitably present in the carboxylic acid or carboxylic anhydride products produced. After traditional distillation, rectification or treatment with certain chemicals, traces of iodide (derivatives) will remain and are difficult to remove. Its existence limits the application of products produced by this method. In particular, it cannot be used in production processes that use iodine-sensitive metals as catalysts. For example, in the process of producing vi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B01J20/18B01J20/30C07C51/47C07C53/08

Inventor 龙英才汪靖沈杰沈浩然

Owner SHANGHAI FUXU MOLECULAR SIEVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com