Patents

Literature

31results about How to "Increase silver loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slowly released type antibiotic medical catheter and preparation method thereof

The invention relates to the technical field of medical apparatus and instruments, which discloses a sustained release type antibacterial medical catheter and a preparation method thereof. A silver inorganic antimicrobial is characterized by high content of silver, safety and the like, and the silver inorganic antimicrobial which adopts zirconium phosphate as a carrier is selected and mixed into catheter material to prepare the sustained release type antibacterial medical catheter that is most widely applied to clinic, such as an antibacterial catheter, an antibacterial central venous catheter, an antibacterial trachea cannula and the like. The catheter has high use safety, wide antibacterial spectrum, good antibacterial effects, antimicrobial constituent sustained release and long duration of antibacterial effects, and can reduce the frequency of replacing medical catheters so as to have safe and convenient clinical use, effectively reduce nosocomial infections related to catheters due to the use of the medical catheters, greatly reduce medical expenses related to anti-infection, and the like, and save medical resources.

Owner:HUADONG HOSPITAL +1

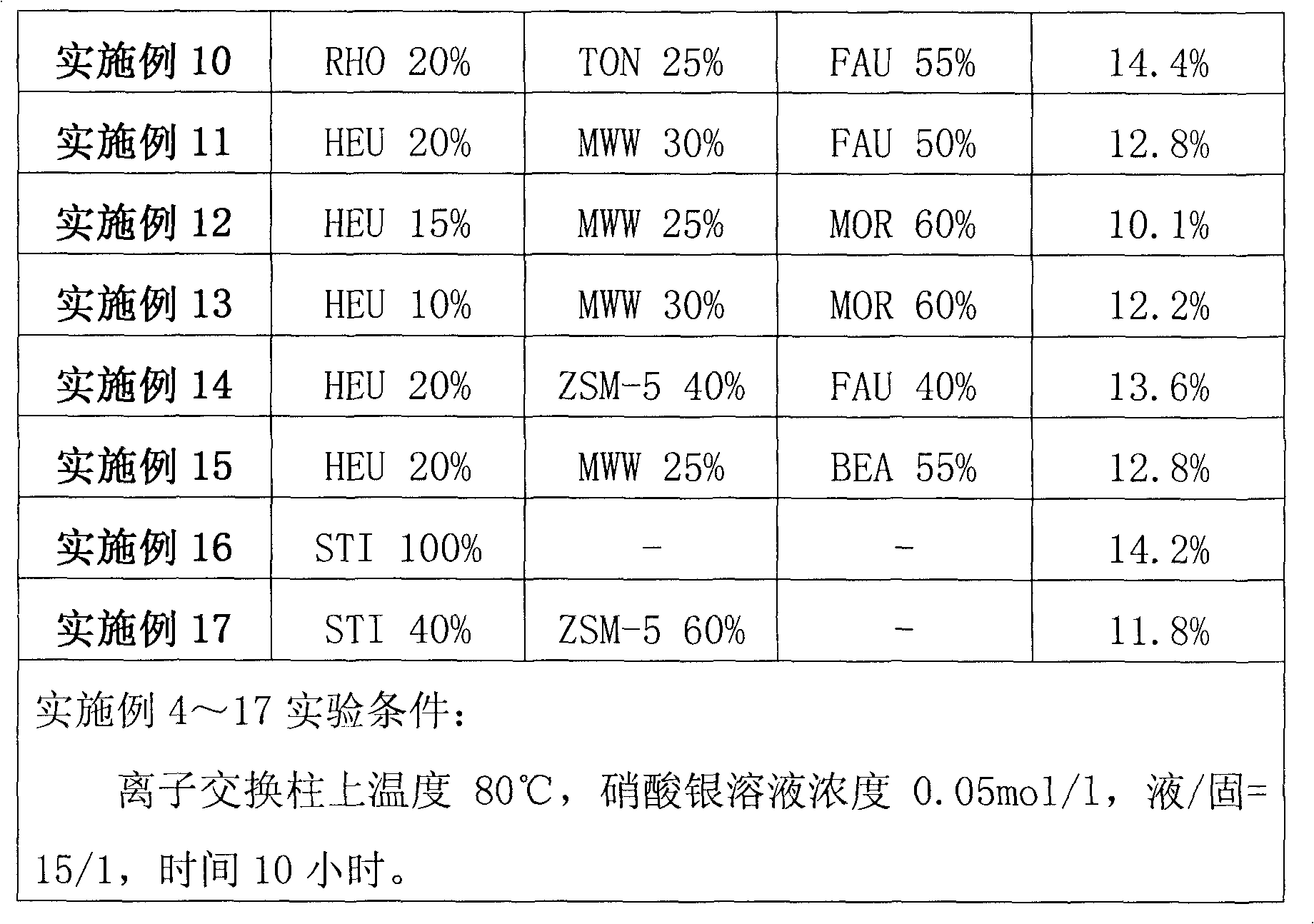

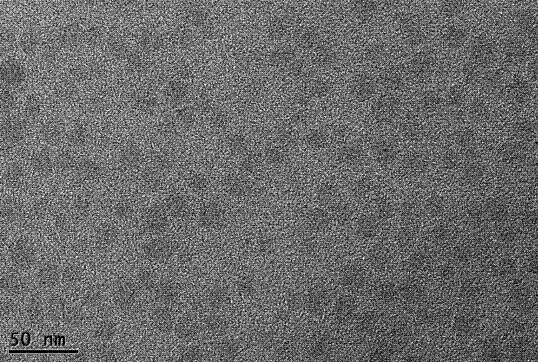

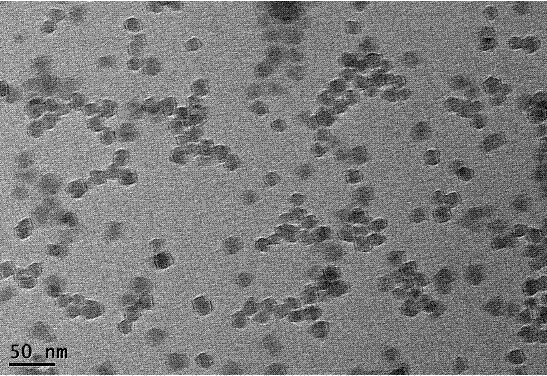

High nanometer sliver loading active carbon and preparation method thereof

InactiveCN105289497AImprove compatibilitySmall particle sizeBiocideOther chemical processesActivated carbonSilver particles

The present invention relates to high nanometer sliver loading active carbon and a preparation method thereof. A purpose of the present invention is to provide a simple nanometer sliver loading active carbon preparation method suitable for industrial production, and nanometer sliver loading active carbon prepared through the method. According to the present invention, the preparation process is divided into four modules such as nanometer silver medium preparation, active carbon pretreatment, silver supporting adsorption, and separation and purification, such that the modular preparation process is achieved, and the quality management control and the efficiency improving are easily achieved; with the method, the nanometer sliver loading active carbons having different uses can be prepared by using different specifications of the active carbon and different particle sizes of the nanometer silver mediums, the combination is diverse, and the control is flexible; the active carbon is pre-treated, such that the number and the density of the nanometer sliver adsorption groups on the surface and the inner wall can be improved so as to improve the silver loading amount (100-10000 ppm) and reduce the silver loss; and with the method, a variety of nanometer silver loading active carbons can be prepared, the silver loading amount and the nanometer silver particle size can be adjusted, and the wide application values are provided.

Owner:成都安平纳医药技术有限责任公司

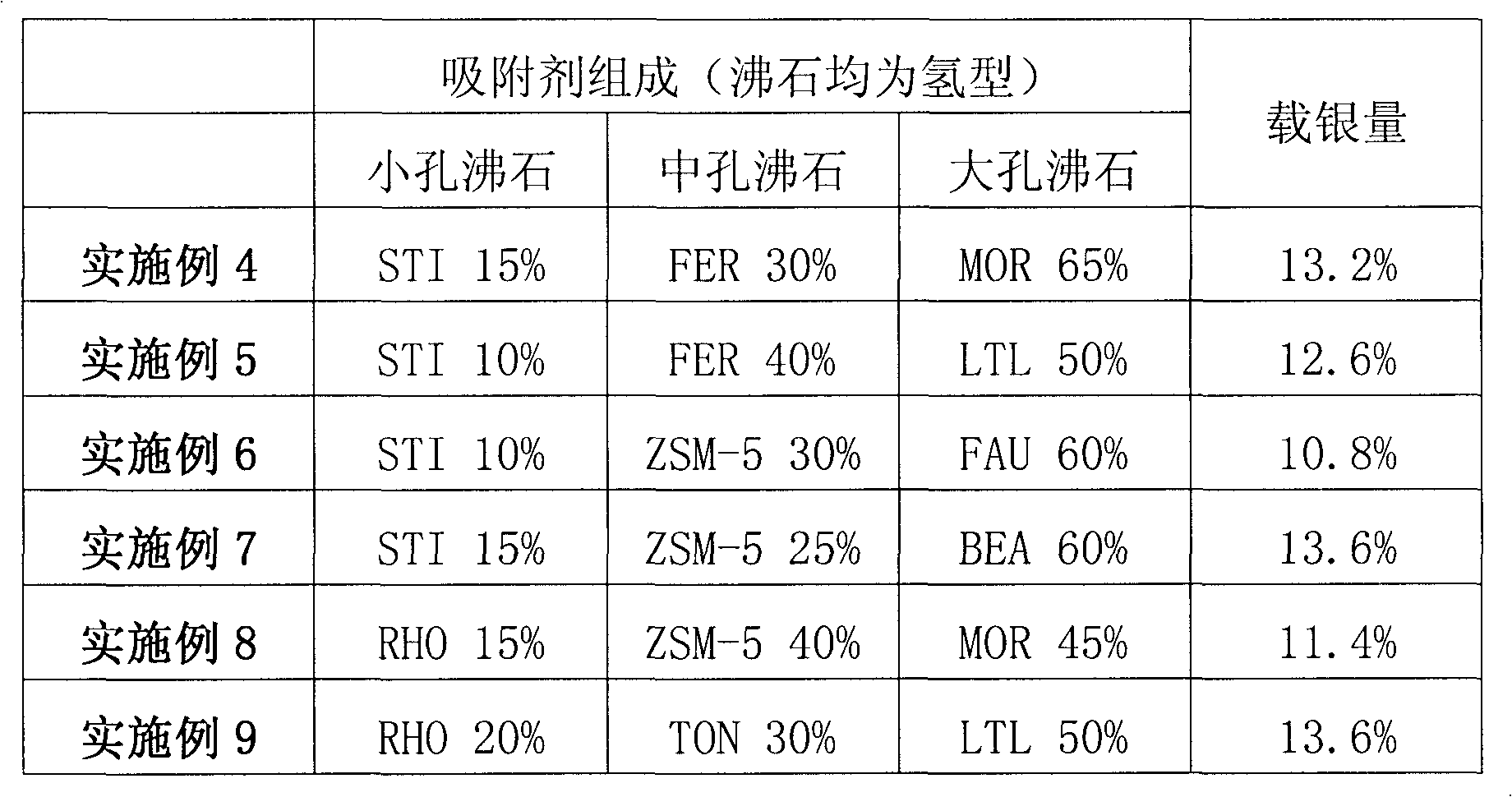

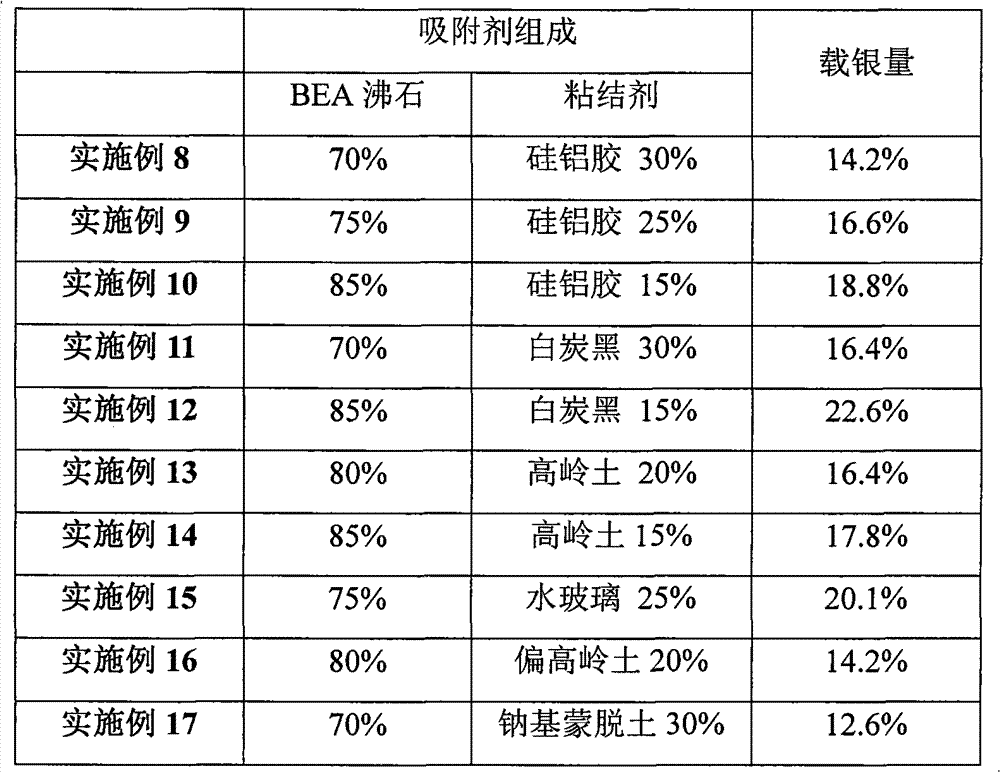

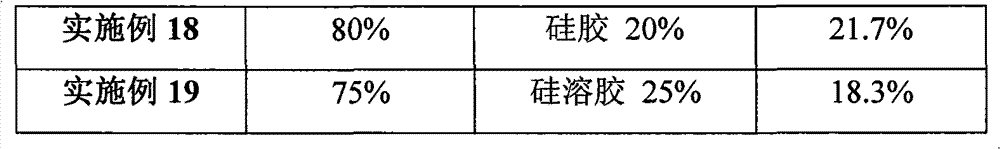

Preparation method, product and applications thereof of acetate deep deiodination adsorbent

InactiveCN101811023AHigh degree of crystallinityHigh particle strengthOther chemical processesCarboxylic compound separation/purificationAdhesiveSorbent

The invention relates to preparation method, product and applications thereof of an acetate deep deiodination adsorbent. The method comprises the following steps of: mixing small-pore, medium-pore and large-pore zeolite molecular sieves with different structures; forming by using an adhesive; generating chemical bonds by hydrothermal strengthening treatment; removing sodium and loading silver by ion exchange to prepare the product. The adsorbent is prepared from the following components in percentage by weight: 10-30% of small-pore zeolite, 20-50% of medium-pore zeolite and 20-70% of large-pore zeolite, and the adhesive accounts for 10-30% of the total weight of the adsorbent. The invention has the advantage that the adsorbent has strong adsorption capability on organic iodide, inorganic iodide and molecular iodine with different sizes in the strong acid medium, the total iodine content in the deep deiodination product is less than 5*10<-9>, and the adsorbent is suitable for being used as raw materials which are used for synthesizing vinyl acetate.

Owner:SHANGHAI FUXU MOLECULAR SIEVE

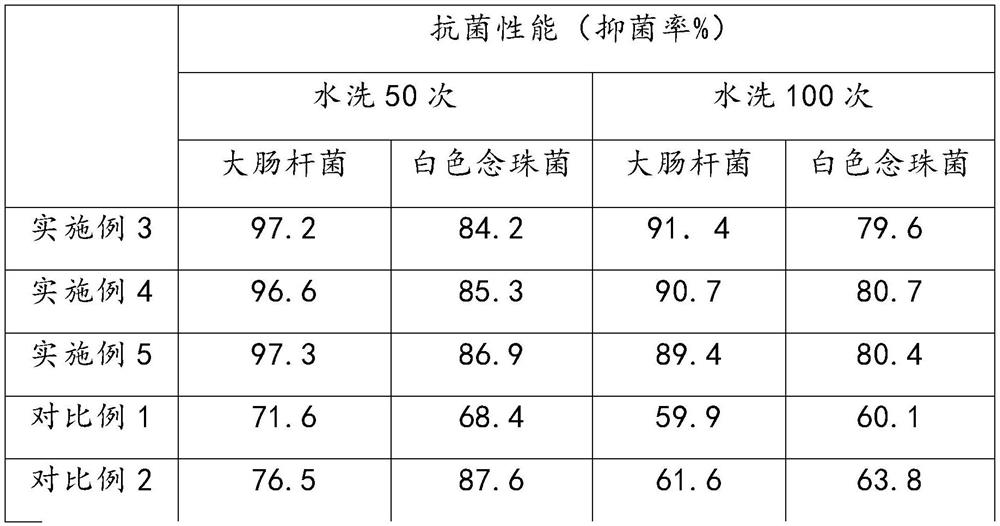

High-efficiency antibacterial fiber and manufacturing method thereof

ActiveCN110512297ASmall sizeIncrease silver loadingArtificial filament heat treatmentMelt spinning methodsFiberMolecular sieve

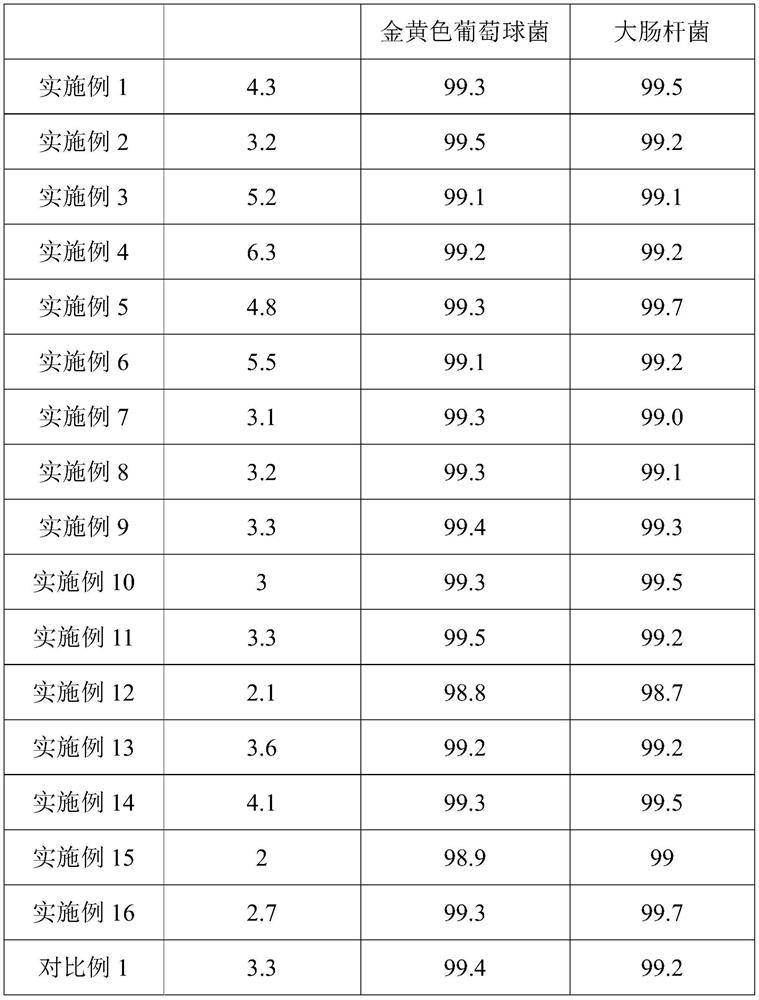

The invention discloses a high-efficiency antibacterial fiber and a manufacturing method thereof. The method mainly comprises the three steps of antibacterial masterbatch preparation, antibacterial fiber preparation and antibacterial FDY cellosilk preparation. Accordingly, by means of the fact that a nanometer silver-carrying molecular sieve has the advantages of being small in crystal size, larger in specific surface area, high in silver-carrying amount and the like, the high-efficiency antibacterial fiber is prepared, the content of an antibacterial agent in the fiber is less than or equal to 1%o, and the sterilization rate reaches 99% or above; after repeated washing, the antibacterial effect is not obviously declined, in the antibacterial fiber preparation process, an organic solvent is not needed, the silver-carrying nanometer molecular sieve is prepared through a one-pot method, no organic template is needed, the process is simple, the cost is low, and environmental friendlinessis achieved.

Owner:MINJIANG UNIV +1

Ecological and environment-friendly coating and preparation method thereof

InactiveCN105524528AImprove purification effectImprove antibacterial propertiesAntifouling/underwater paintsPaints with biocidesWater basedOxygen ions

The invention discloses an ecological and environment-friendly coating and a preparation method thereof. The coating is prepared from raw materials in parts by weight as follows: 0.05-0.15 parts of a pH regulator, 0.3-0.8 parts of a dispersant, 10-15 parts of a hydroxyethyl cellulose solution, 0.1-0.4 parts of a wetting agent, 0.1-0.4 parts of an antifoaming agent, 1-10 parts of negative oxygen ion powder, 10-20 parts of titanium dioxide, 0.05-0.2 parts of a molecular sieve silver-loaded antibacterial agent, 0.1-0.4 parts of a preservative, 2-10 parts of quartz / nano-titanium dioxide compound slurry, 10-20 parts of superfine quartz powder slurry, 15-40 parts of a water-based acrylic emulsion, 0.2-1.0 part of a thickening agent and 20-30 parts of deionized water. The coating has good performance, the formaldehyde purification rate is higher than 95%, the formaldehyde purification durability is longer than 90%, the antibacterial effect is higher than 90%, and the negative oxygen ion release amount is larger than 8000 per cubic centimeter.

Owner:GUIZHOU LIANHE NEW BUILDING MATERIAL

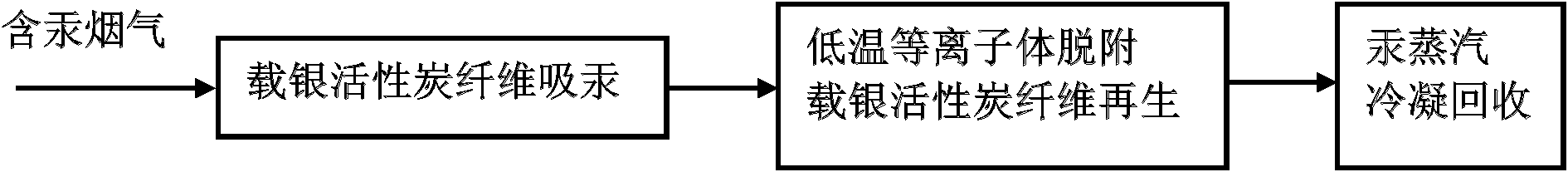

Method for purifying and recycling mercury in flue gas

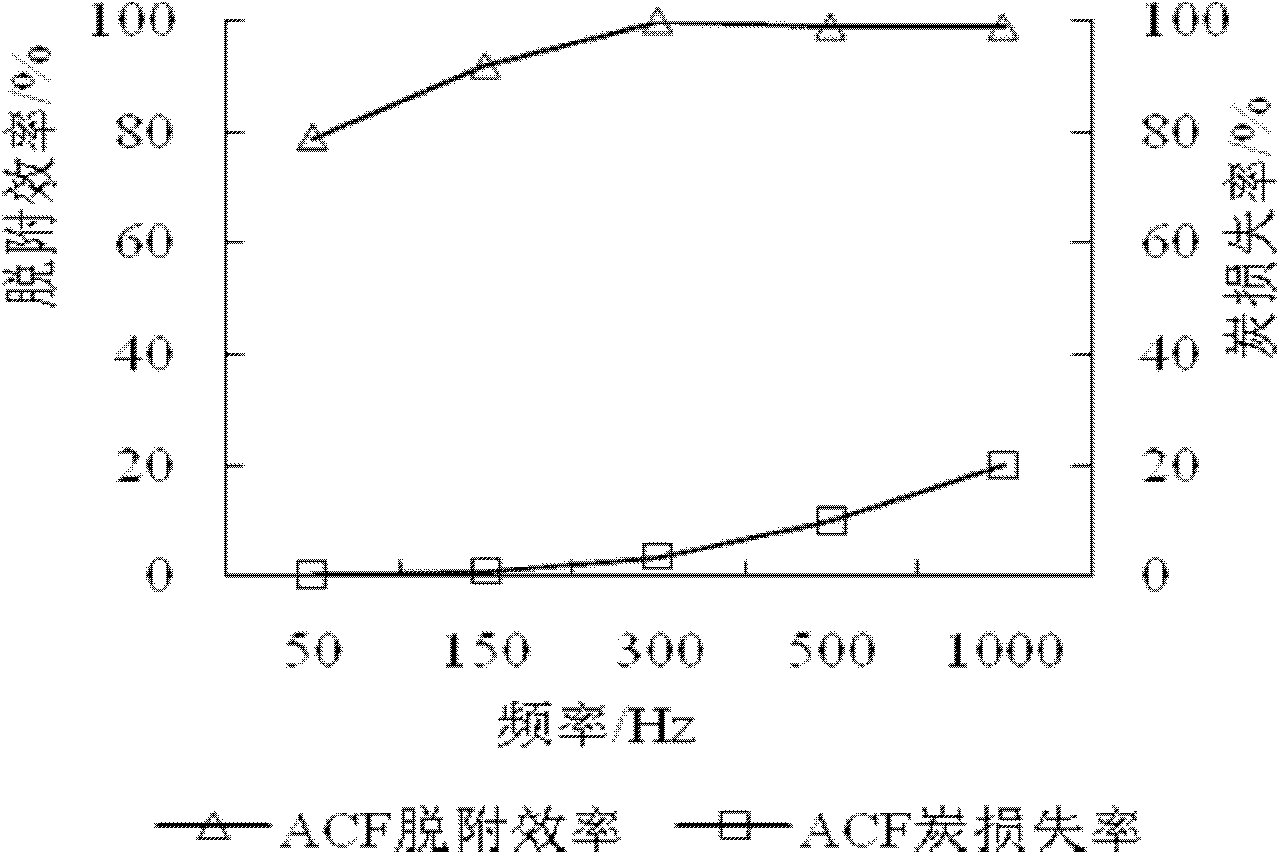

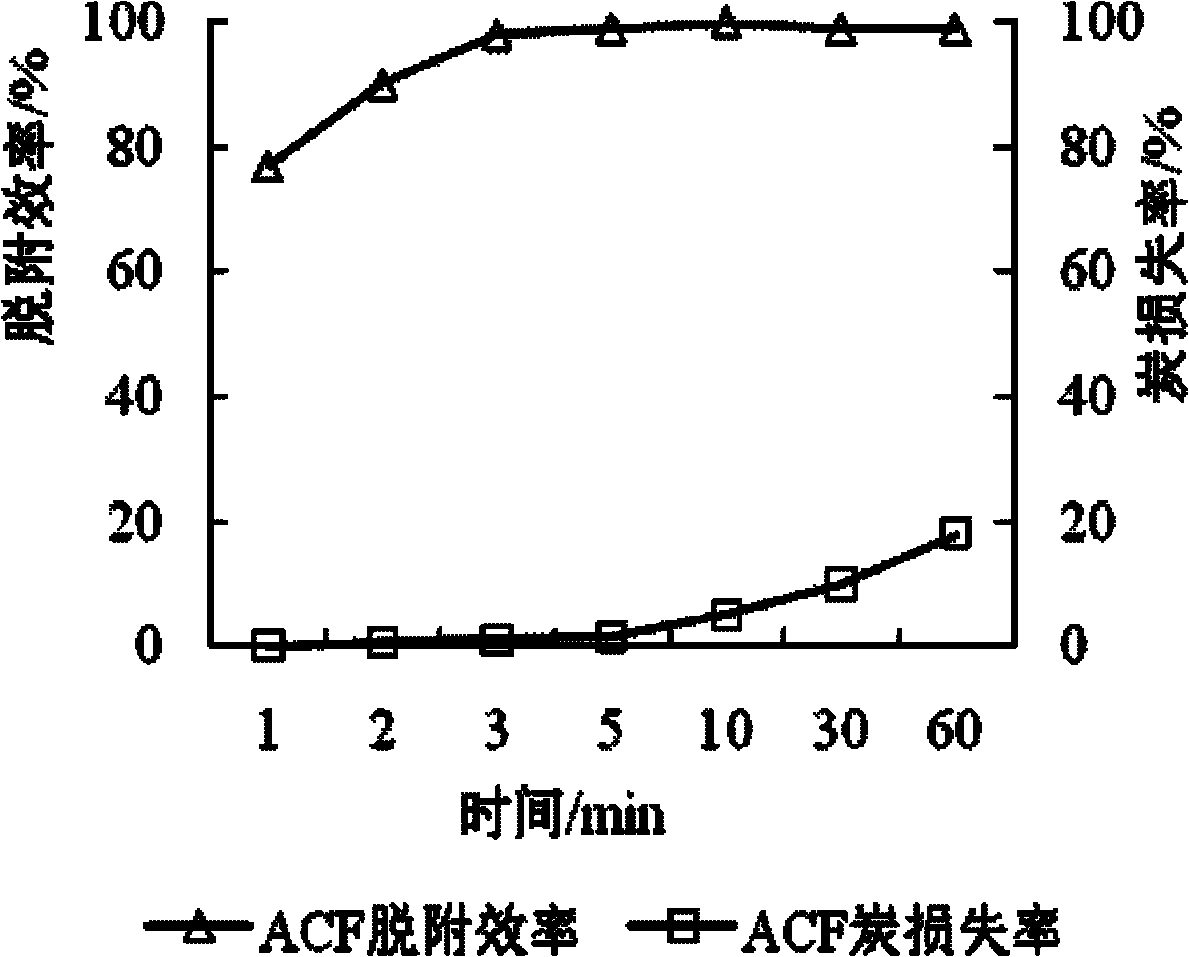

InactiveCN102188879AImprove adsorption capacityGood desorption regeneration performanceOther chemical processesDispersed particle separationWater bathsFiber

The invention relates to a method for purifying and recycling mercury in flue gas, wherein the method is applicable to mercury desorption from coal-fired flue gas, and mercury purification and recycling from mercury-contained flue gas in nonferrous industries and belongs to the fields of atmospheric pollution control technologies and heavy metal pollution control. The method comprises the following steps: immerging activated carbon fiber in a 15-45wt% phosphoric acid solution or zinc chloride solution or ammonium salt solution for 12-24 hours, and then taking out the immerged activated carbonfiber, and airing the immerged activated carbon fiber for standby; adding the dried activated carbon fiber into a prepared 0.001-1 mg / L sliver-contained ion solution, agitating for 4-24 hours in a thermostatic water bath, filtering out the solution, flushing the activated carbon fiber repeatedly by using de-ionized water, filtering out the solution, flushing the activated carbon fiber repeatedly by using distilled water, and then drying the flushed activated carbon fiber at 50-105 DEG C in vacuum; regenerating the activated carbon fiber by using low-temperature plasma after the prepared silver-loaded activated carbon fiber is saturated with adsorbed mercury; and further recycling the volatilized mercurial vapor which enters a condenser, and flows back to a storage tank after being condensed. The method for purifying and recycling the mercury in the flue gas has the effects of rapidness, high efficiency, and low loss of carbon for the mercury desorption; and in addition, the mercurial vapor is reused by means of condensation and recycling.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Preparation method of nano-divalent silver-supported silica gel antiseptic dressing

InactiveCN107233616AImprove stabilityEfficient bactericidal effectBandagesHydrogen-Ion ConcentrationsGlycerol

The invention discloses a preparation method of a nano-divalent silver-supported silica gel antiseptic dressing. The preparation method comprises the following steps: (1) weighing 85-96 parts of deionized water, adding 1-5 parts of a hydrogen peroxide solution with the concentration of 30%, adding 0.01-0.05 part of nano-divalent silver, and conducting marking as a C solution; (2) regulating the C solution with a nitric acid water solution until the hydrogen ion exponent pH value of the C solution is 2-5, and conducting marking as a D solution; (3) adding 3-5 parts of organic silicon to the D solution, conducting hydrolysis for 2 hours, and conducting marking as an E solution; and (4) regulating the E solution with sodium hydroxide until the pH value is 6-7, then adding 1-2 parts of glycerol, and finally conducting standing and aging for 48 hours for gel formation. Through the above mode, the preparation method of the nano-divalent silver-supported silica gel antiseptic dressing integrates the excellent stability of silica gel and the high-efficiency sterilizing effect of nano-divalent silver, is high in the amount of supported silver and very stable, has long-term sterilization and antibacterial effects, can be mass produced and is nontoxic and harmless.

Owner:苏州聚容纳米科技有限公司

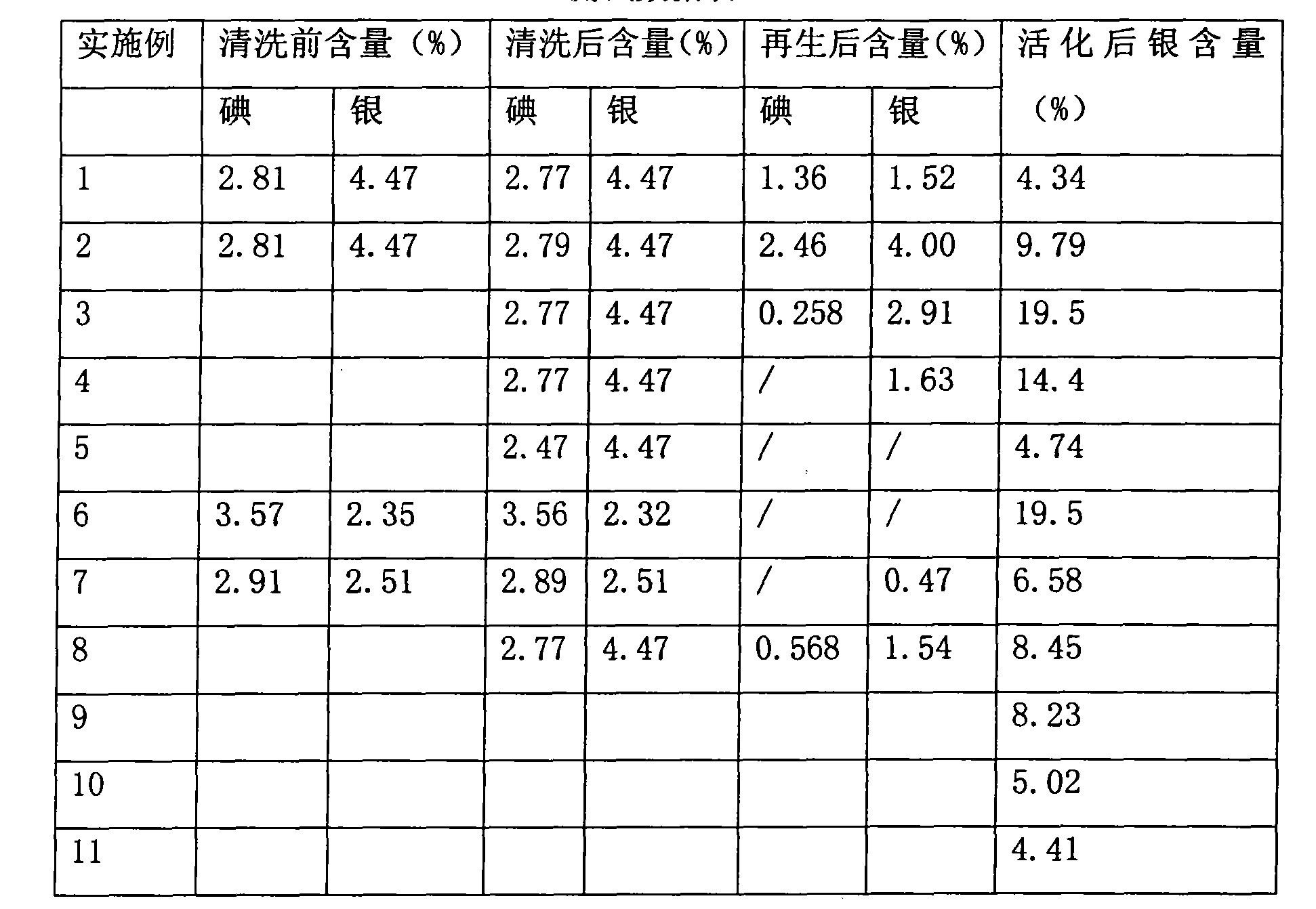

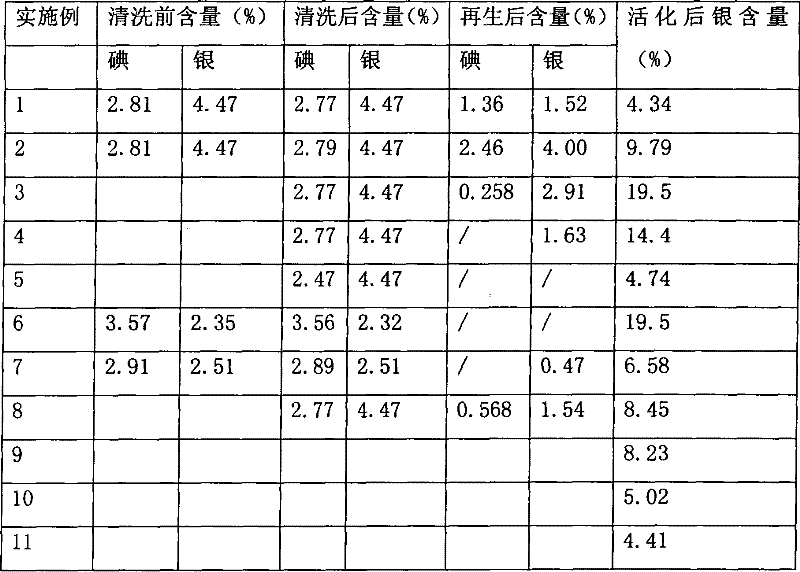

Regeneration and activation technique of iodine pollution solid adsorbent

ActiveCN101380567AEffective desorptionInhibitory activityDispersed particle separationCombustible gas purificationAcetic acidDesorption

The invention relates to a regeneration and activation technique of solid adsorbent polluted by iodine, which comprises the following steps in sequence: the solid adsorbent polluted by iodine is placed in 0.01 to 1 percent of acetic acid for cleaning; (2) the cleaned adsorbent is soaked in sodium thiosulfate solution with the concentration of 0.01 to 2 percent in static state or placed in a column and the sodium thiosulfate solution with the concentration of 0.01 to 2 percent is injected for regeneration so as to lead the pollutants in effective pore channels of the adsorbent polluted by iodine to be precipitated completely; (3) then the obtained adsorbent is placed in the column and ion exchange is carried out by injecting active metal Ag<+> solution till the concentration of the active metal Ag<+> on the solid adsorbent reaches the concentration before the solid adsorbent is polluted. The invention has low energy consumption and convenient operation, in particular to the regenerative technique condition that any heating facility is not used, the concentration of the used regenerative liquid is low and can effectively desorb iodine pollutants; the appearance of the activated adsorbent is same as new carriers, is off white, is characterized by high silver-loaded quantity and high adsorption and effectively prolongs the service life of the adsorbent, thus reducing the cost of iodine desorption.

Owner:SHANGHAI HUAYI ENERGY CHEM

Quick-forming organic antiseptic protective film for metal surface

ActiveCN106280808AAvoid corrosionGood water solubilityAntifouling/underwater paintsPaints with biocidesTectorial membraneAluminum silicate

The invention relates to the field of organic coatings and discloses a quick-forming organic antiseptic protective film for the metal surface. The organic antiseptic protective film is formed by curing an organic antiseptic protective coating, the organic antiseptic protective coating is prepared from components in parts by mass as follows: 40-50 parts of an acrylic emulsion, 5-15 parts of inositol hexaphosphate, 5-15 parts of hydrated magnesium-aluminum silicate filler, 3-7 parts of iron oxide red, 3-7 parts of antibacterial particles, 2-4 parts of a compound tackifier, 3-7 parts of pigment, 0.5-1.5 parts of a dispersing agent, 0.5-1.5 parts of a defoaming agent, 3-7 parts of ethanol and 10-20 parts of water. The quick-forming organic antiseptic protective film has high binding force with the metal surface, no bubbles are generated after the film is formed, and the organic antiseptic protective film is corrosion resistance and ageing resistance and has an antibacterial property.

Owner:杭州朱炳仁铜艺股份有限公司

Prepn process of sea water desalting agent for desalting sea water

InactiveCN1974416AEfficient removalLower pHSeawater treatmentWater/sewage treatment by neutralisationWater desalinationIon exchange

The present invention relates to preparation process of sea water desalting agent, and belongs to the field of sea water desalting technology. The sea water desalting agent is prepared through soaking process including the following steps: 1. preparing acid zeolite through soaking zeolite in acid solution or ammonium salt solution for ion exchange at 25-80 deg.c, washing, filtering and stoving; 2. preparing silver-carrying acid zeolite through soaking the acid zeolite in silver ion solution for ion exchange at 60-120 deg.c in heliophobic condition, washing, filtering and stoving; and 3. mixing the silver-carrying acid zeolite, silver oxide and barium hydroxide in heliophobic condition to obtain the sea water desalting agent. The process is simple and suitable for industrial production, and has facile material. Adopting unique vacuumizing method can result in silver carrying amount up to 22 %.

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

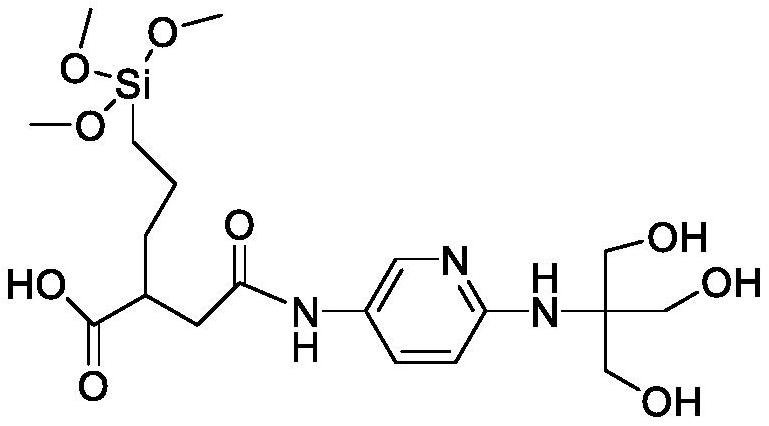

Silver-loaded antibacterial master batch and application thereof

PendingCN114350070AIncrease silver loadingIncreased durabilityMonocomponent polyesters artificial filamentArtifical filament manufacturePolymer scienceHyperbranched polyester

The invention relates to a silver-loaded antibacterial master batch and application thereof, and belongs to the technical field of antibacterial materials. The silver-loaded antibacterial master batch is prepared from the following raw materials in parts by weight: 15 to 25 parts of silver-loaded hyperbranched polyester, 0.1 to 1 part of compatibilizer and 30 to 40 parts of carrier resin. The silver-loaded hyperbranched polyester contains a large number of cavities, each cavity contains a pyridine ring, nitrogen atoms on the pyridine ring and silver ions form coordinate bonds, then silver loading is completed, and the high silver loading amount can be achieved; a siloxane chain contained in a molecular chain of the hyperbranched polyester has excellent wettability, so that the hyperbranched polyester and the carrier polyester have good compatibility, and a branched structure of the hyperbranched polyester promotes the hyperbranched polyester to be dispersed more uniformly in the carrier resin; the hyperbranched polyester contains a large number of terminal hydroxyl groups, so that the bonding property between the hyperbranched polyester and carrier resin is relatively strong. Therefore, the antibacterial master batch has good antibacterial property and durability of the antibacterial property.

Owner:安徽海铭塑业有限公司

Plastic composite pipe with antibacterial function and for hot and cold water

InactiveCN108410067AImprove impact resistanceAccelerated corrosionFlexible pipesRigid pipesGlass fiberWater circulation

The invention discloses a plastic composite pipe with an antibacterial function and for hot and cold water. The plastic composite pipe comprises the following main components by mass: 100 parts of a matrix, 15 to 30 parts of glass fibers, 0.6 to 3.2 parts of a silver-loaded antibacterial agent and 0.006-0.096 part of a coupling agent, wherein the matrix is any one of selected from the group consisting of PPR, PB, PPB, PE-RT, PE-X, WPP and C-PVC; the glass fibers can enhance the mechanical properties of the pipe; and the silver-loaded antibacterial agent can effectively improve the antibacterial properties of the pipe and avoid secondary pollution during water circulation of a sponge city. According to the invention, the silver-loaded antibacterial agent is added to improve the antibacterial properties of the pipe and prolong the service life of the pipe, and the pipe is widely applicable to the field of hot and cold water transportation.

Owner:CHENGDU CHUANSHENG PLASTIC

Silver-loaded zirconium phosphate as well as preparation method and application thereof

InactiveCN112674112AIncrease silver loadingImprove antibacterial propertiesBiocideFungicidesPhosphoric acidCombinatorial chemistry

The invention provides silver-loaded zirconium phosphate as well as a preparation method and application thereof. The preparation method comprises the step of reacting a mixed solution containing a water-soluble silver salt, a reducing agent and zirconium phosphate to obtain the silver-loaded zirconium phosphate. According to the method, an in-situ reduction method is adopted, silver ions are directly subjected to a reduction reaction on the surface of zirconium phosphate and in mesopores through a reducing agent, and the silver-loaded zirconium phosphate is obtained. The silver-loaded zirconium phosphate provided by the invention has relatively high silver loading capacity and is suitable for being used as an antibacterial agent, and the preparation method provided by the invention is simple and easy to operate and mild in process conditions.

Owner:SURGSCI SHENZHEN MEDICAL TECH CO LTD

Antibacterial and fouling-resistant PVDF (Polyvinylidene Fluoride) ultrafiltration membrane for water filtration

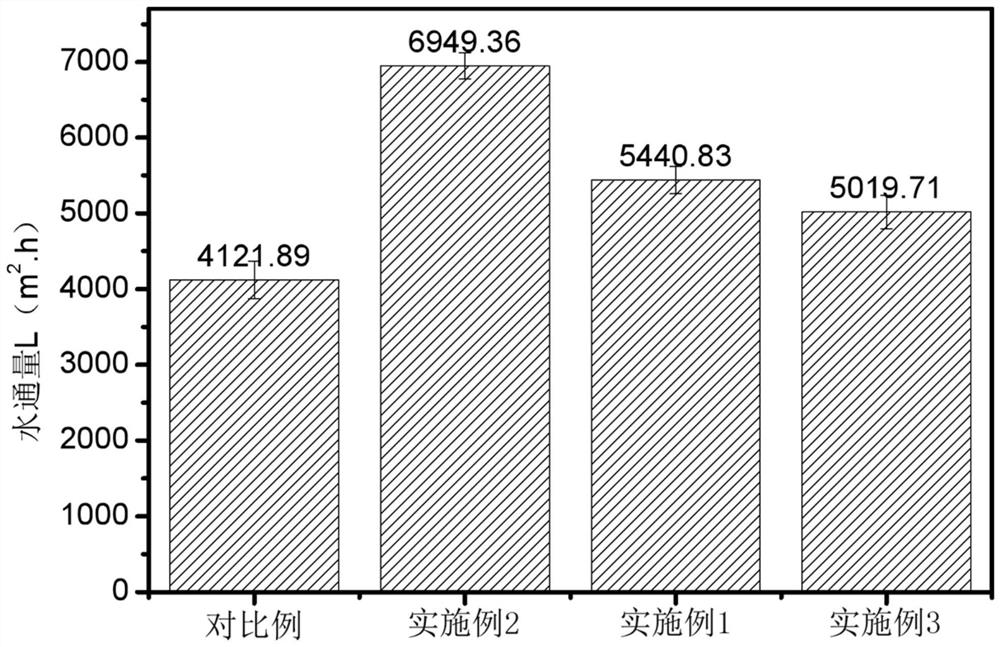

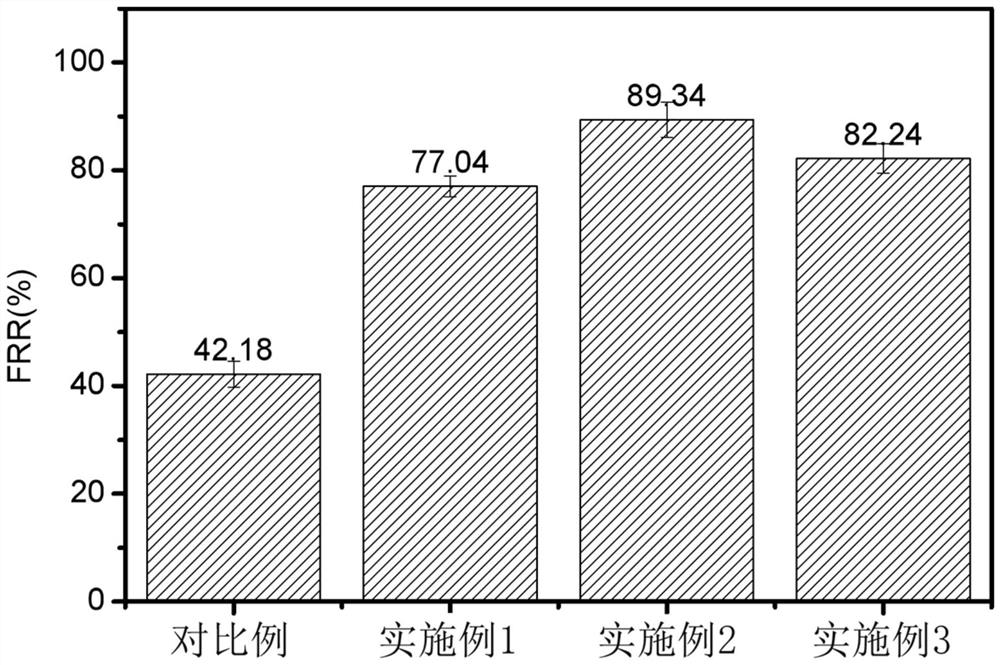

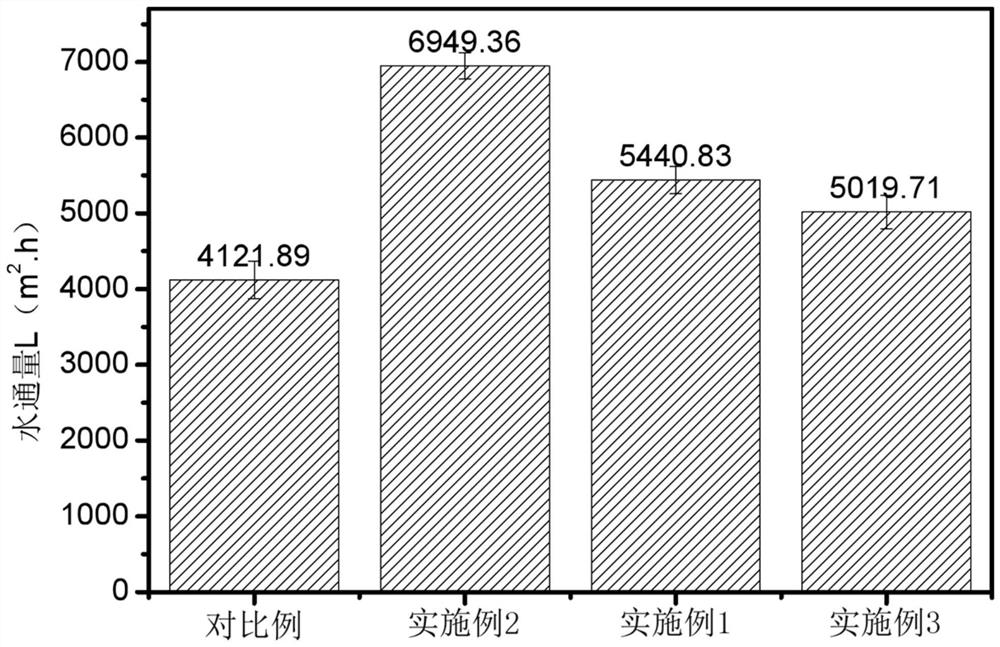

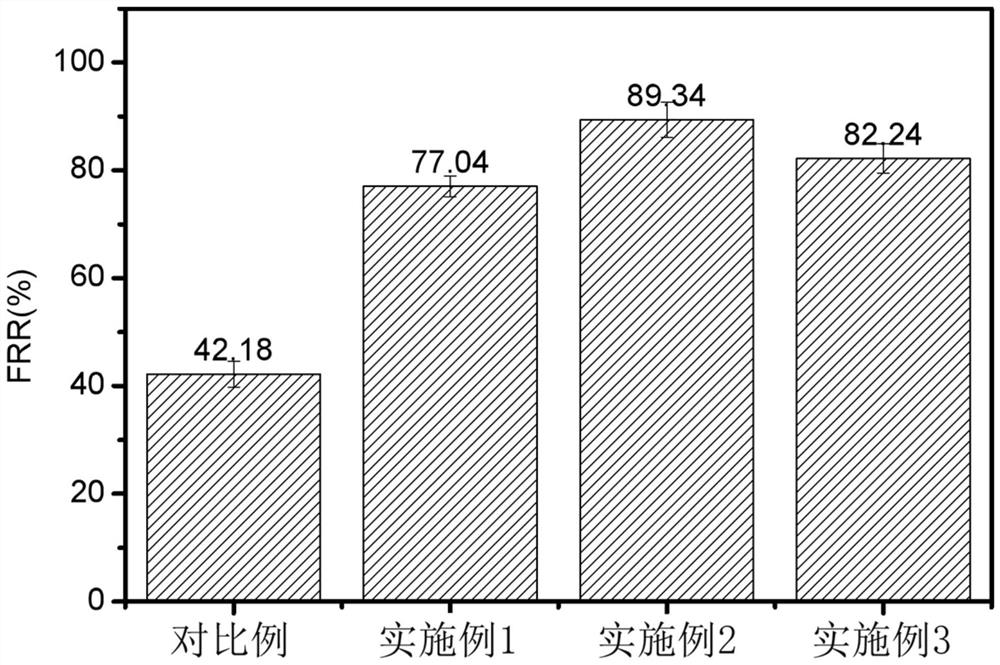

ActiveCN107875865AModified HydrophilicModified AntibacterialMembranesUltrafiltrationUltrafiltrationFiltration

The invention discloses an antibacterial and fouling-resistant PVDF (Polyvinylidene Fluoride) ultrafiltration membrane for water filtration. The ultrafiltration membrane mainly comprises the followingcomponents in parts by weight: 100 parts of polyvinylidene fluoride, 15-35 parts of polyethylene glycol and 3-15 parts of silver-loaded chitosan. The preparation method comprises the following steps:dissolving polyvinylidene fluoride and polyethylene glycol into an N-methyl pyrrolidone solvent, and uniformly mixing by a solution blending method; preparing a silver-loaded chitosan solution by chitosan, dipping a polyvinylidene fluoride membrane into the silver-loaded chitosan solution, and drying, thereby obtaining a hydrophilic antibacterial and fouling-resistant PVDF micro-porous membrane.The PVDF micro-porous membrane prepared by the method disclosed by the invention has excellent hydrophilic property and can achieve the effects of killing microbial flora on the surface and reducing the adhesion amount of proteins in sewage. Meanwhile, the proteins can be inactivated, and the service life of the PVDF membrane is effectively prolonged.

Owner:河南豫膜环保科技有限公司

A kind of preparation technology of inorganic-organic composite complex antibacterial agent

ActiveCN113498786BGuaranteed application effectImprove heat resistanceBiocideDisinfectantsCombinatorial chemistryChloride

The invention discloses a preparation process of an inorganic-organic composite antibacterial agent, and relates to the technical field of inorganic-organic composite antibacterial agents. The invention solves the anti-discoloration ability of conventional silver ion antibacterial agents through the preparation of complexes Poor, poor antibacterial durability and poor salt resistance, successfully realized the application of the prepared antibacterial agent in light-colored products, in alkaline environments, and in products or environments containing chloride ions, expanding the application range of antibacterial agents, And ensure the application effect of antibacterial agent.

Owner:吉祥三宝高科纺织有限公司

Method for plating silver on surface of carbon material

InactiveCN111074243AImprove adsorption capacityImprove bindingLiquid/solution decomposition chemical coatingElectromagnetic shieldingSilver particles

The invention relates to a method for plating silver on the surface of a carbon material. The method comprises the steps that firstly, the carbon material is subjected to surface modification througha surface sizing agent, then a silver salt solution is added, after the solution is evenly mixed, drying is conducted, and high-temperature heat reduction is conducted in the inert atmosphere to obtain the surface silver-plated carbon material. According to silver particles in the obtained silver-plated carbon material, the size range is 10-600 nm, and the silver content is 15-60wt.%. A preparation process is simplified, impurity residue is lowered, the binding strength of a coating is improved, the conductivity of the carbon material is enhanced, and the method has important application valuein the fields such as conductive composite materials and electromagnetic shielding materials.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI +1

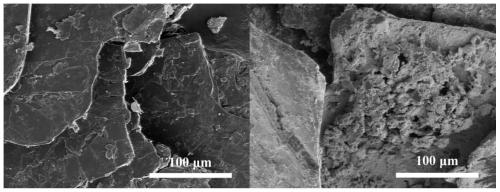

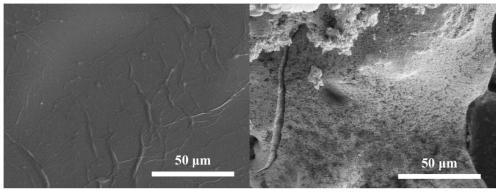

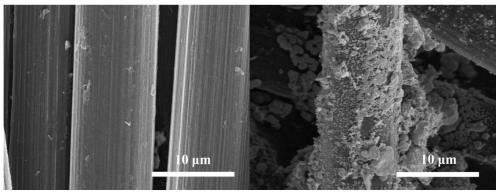

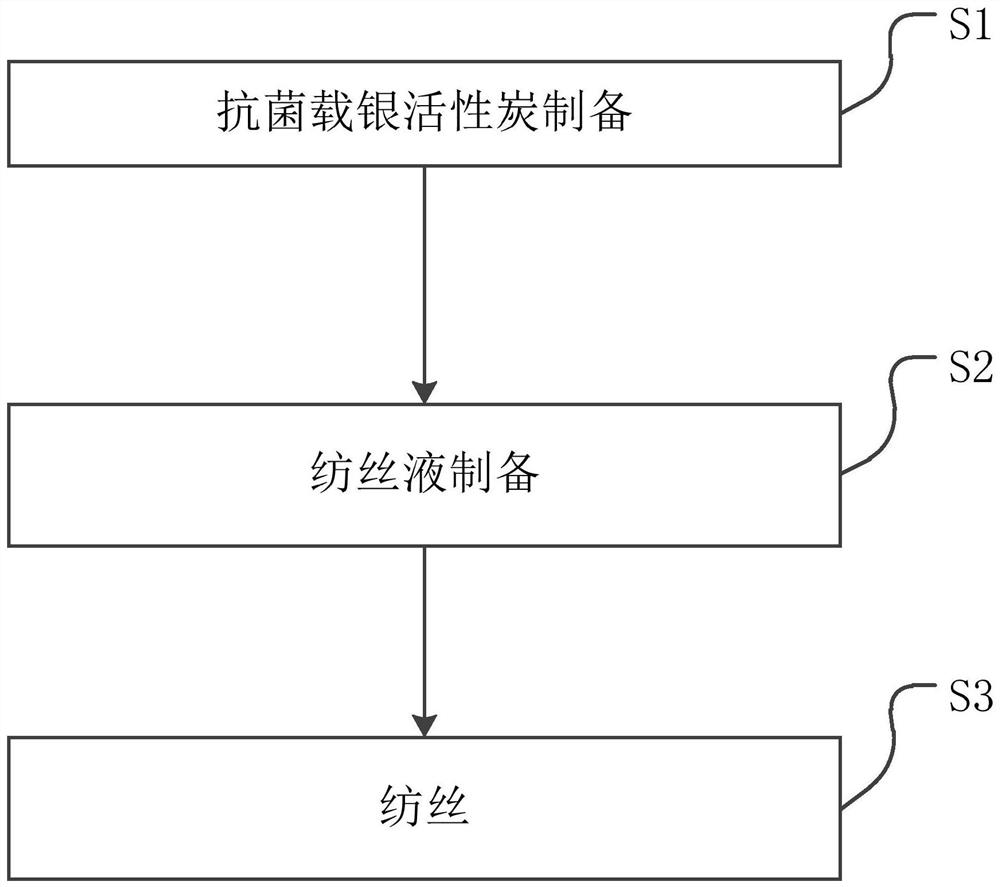

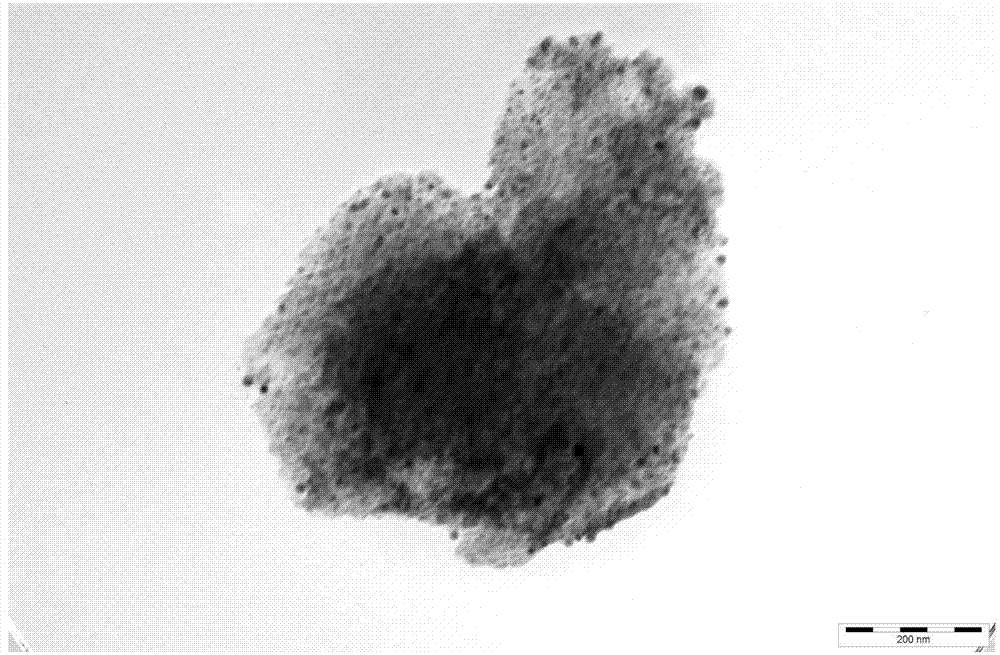

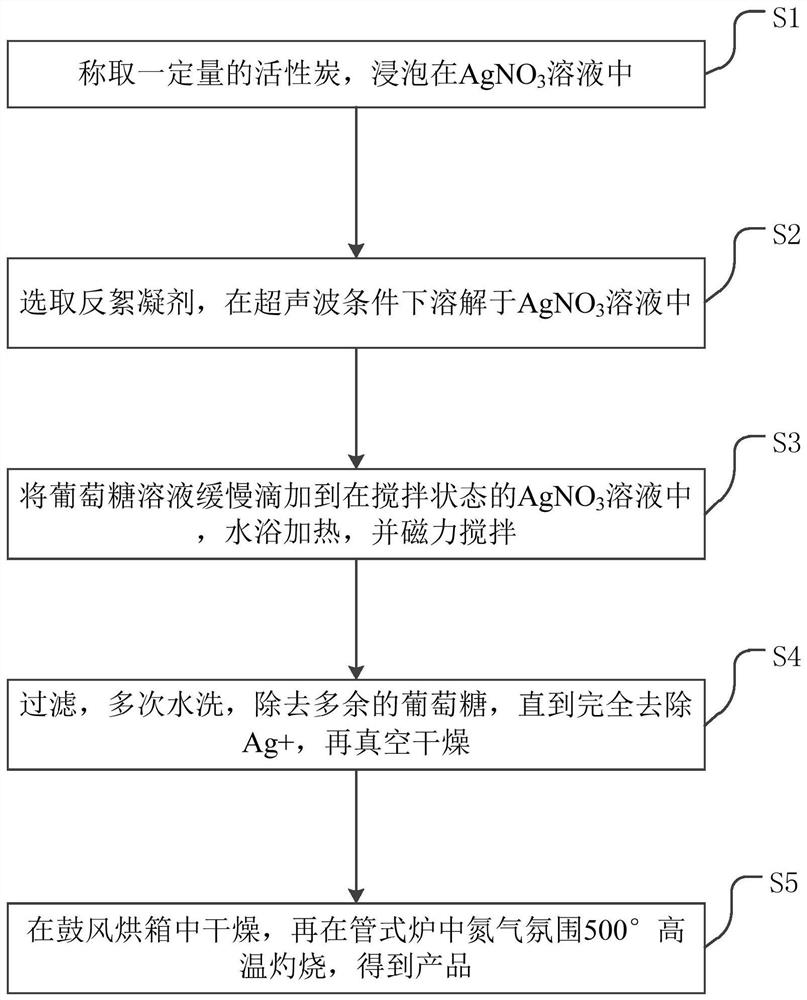

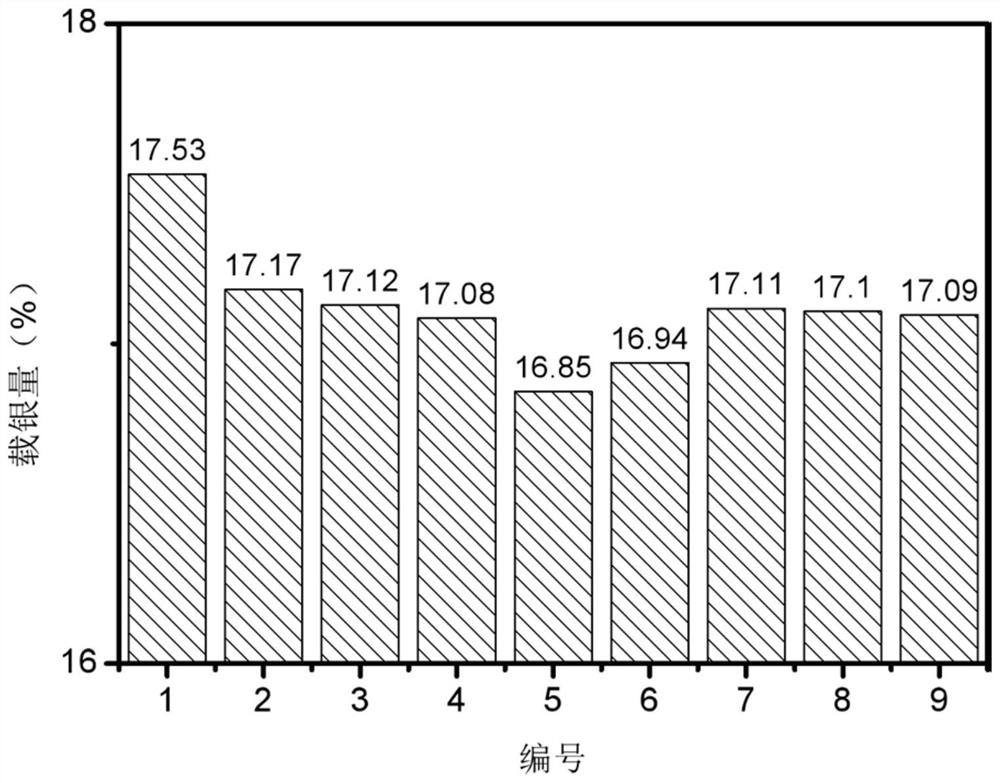

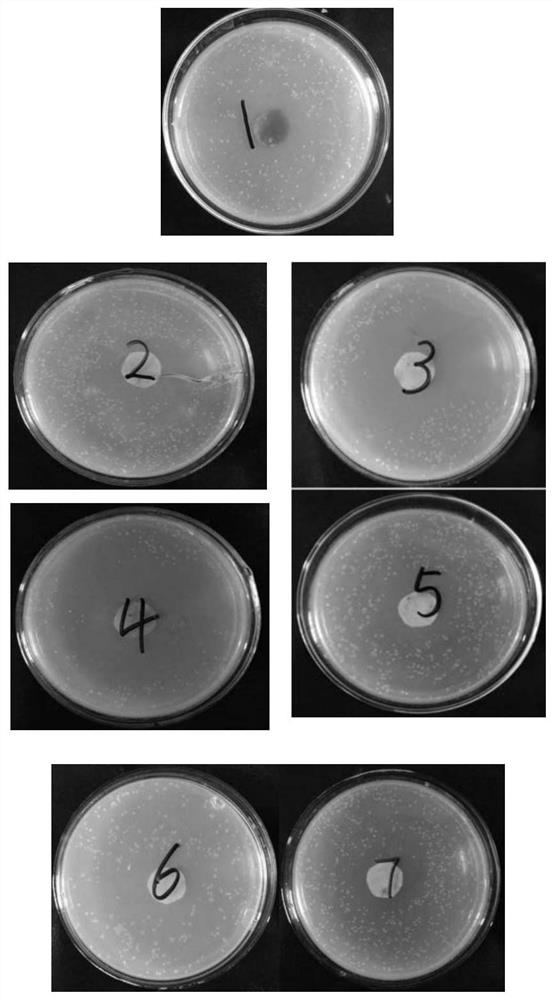

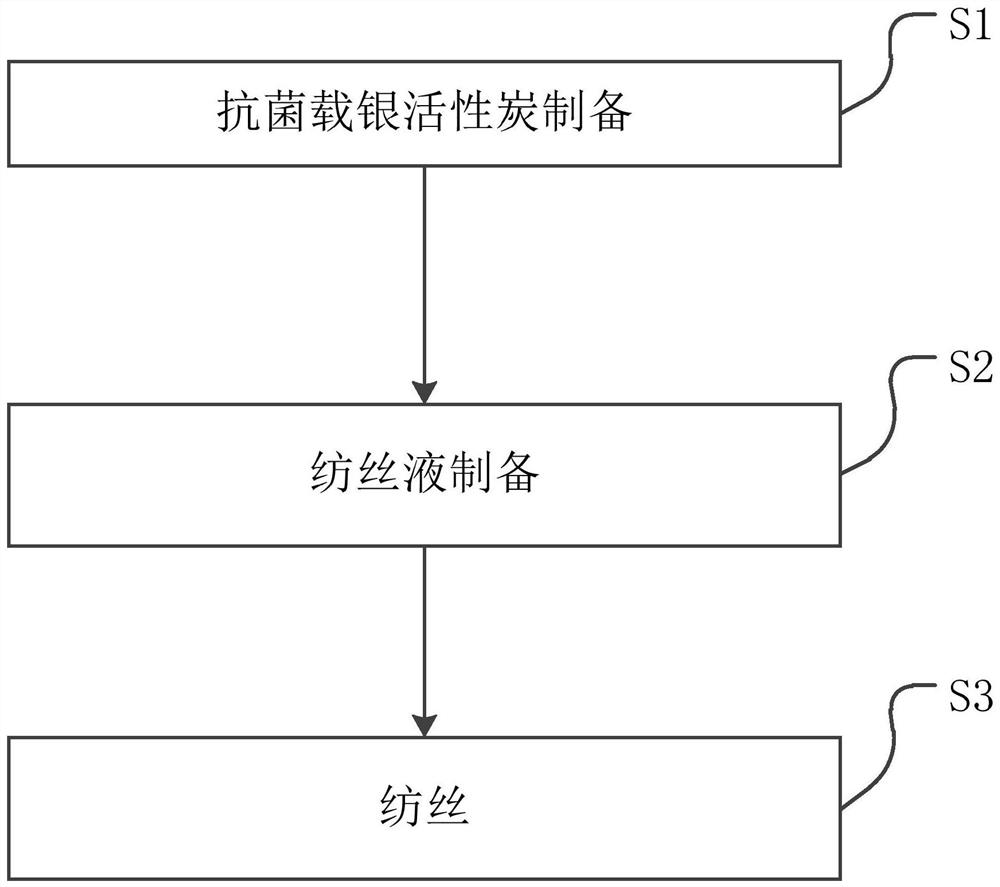

Preparation method of silver-loaded activated carbon antibacterial fiber membrane

ActiveCN111910344AIncrease silver loadingGood dispersionElectro-spinningMonocomponent synthetic polymer artificial filamentActivated carbonSpinning

The invention discloses a preparation method of a silver-loaded activated carbon antibacterial fiber membrane. The preparation method comprises the following steps of step 1) preparing antibacterial silver-loaded activated carbon: soaking activated carbon in an AgNO3 solution, selecting a deflocculating agent, dissolving in the AgNO3 solution, slowly dropwise adding a glucose solution into the AgNO3 solution in a stirring state, performing heating in a water bath, performing magnetic stirring, filtering a product, performing washing with water, removing glucose until Ag<+> is completely removed, performing vacuum drying, finally, drying a product in a blast oven, and firing the product in a tubular furnace at a high temperature of 500 DEG C in a nitrogen atmosphere to obtain the silver-loaded activated carbon; 2) preparing a spinning solution, wherein polyacrylonitrile is dissolved in a certain volume of N, N-dimethylformamide solution, heating and magnetic stirring are carried out, aspinning solution is obtained, silver-loaded activated carbon is added into the spinning solution, magnetic stirring is carried out for 8 h after sealing is carried out, an antibacterial spinning solution is obtained; and 3) performing spinning, wherein spinning is carried out through an electrostatic spinning device. Through the method, the fiber membrane has the good antibacterial property.

Owner:江苏鑫林环保设备有限公司

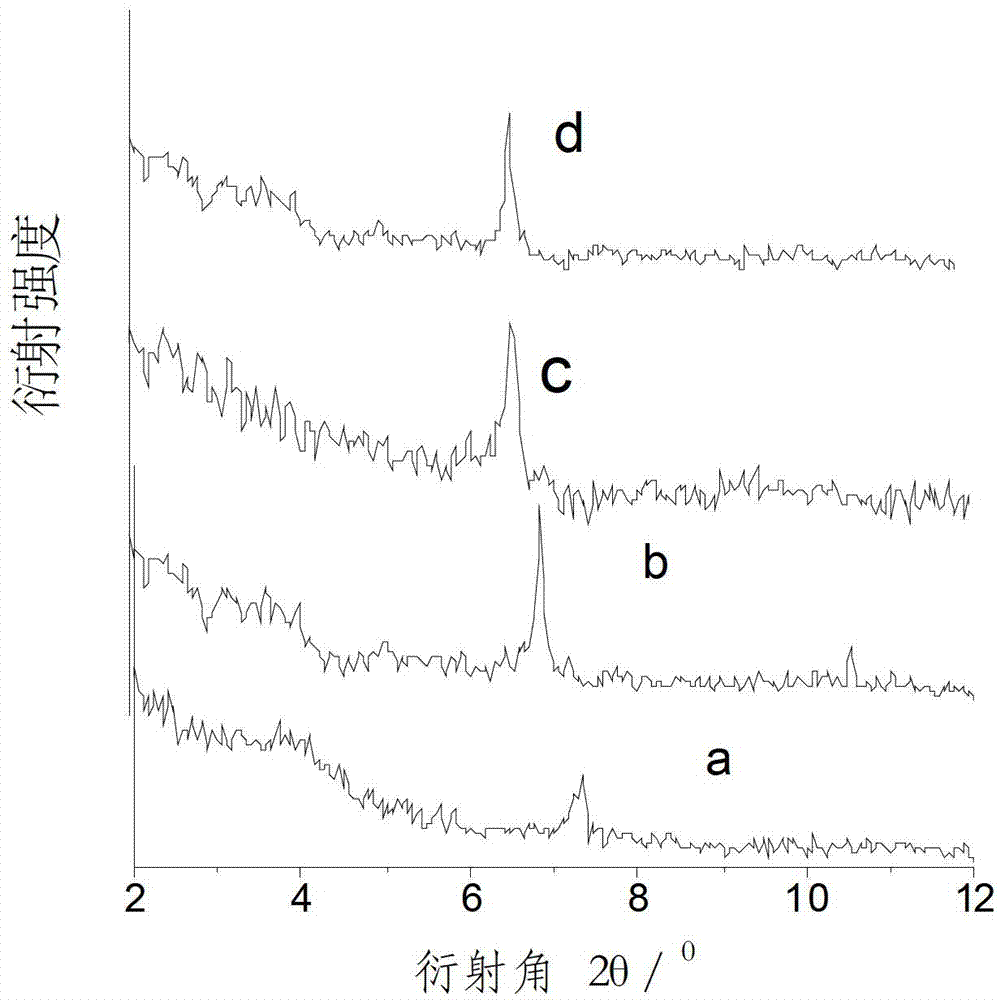

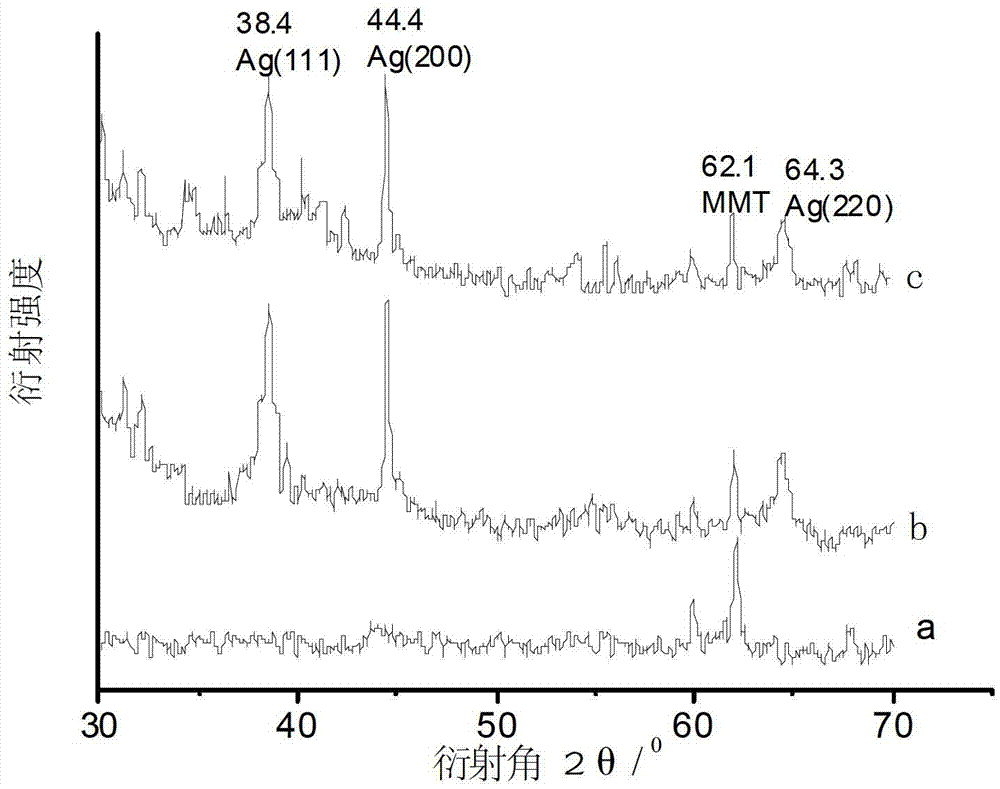

Silver-loading modified montmorillonite antibacterial agent, preparation method and application thereof

InactiveCN103461382BImprove bindingIncrease silver loadingBiocideDisinfectantsSulfur amino acidAdhesive

The invention discloses a silver-loaded modified montmorillonite antibacterial agent, a preparation method and an application thereof. The antibacterial agent uses sulfur-containing amino acid-modified montmorillonite as the carrier for loading silver ions. Firstly, the sulfur-containing amino acid is used to modify the montmorillonite, and then the silver ions are loaded between the modified montmorillonite layers through ion exchange. Silver ions are transformed into nano-silver by means of ultraviolet radiation, and a silver-loaded modified montmorillonite antibacterial agent is obtained. The silver-loaded modified montmorillonite antibacterial agent of the present invention has good antibacterial performance, and can be mixed into plastics, coatings, adhesives, ceramic materials and products thereof, so that it has excellent antibacterial function.

Owner:GUANGDONG PHARMA UNIV

High silver supported zeolite molecular sieve acetate deiodinase adsorber and preparation method thereof

ActiveCN101829542BHigh degree of crystallinityHigh particle strengthOther chemical processesSorbentIon exchange

The invention belongs to the chemical technical field and relates to a high silver supported zeolite molecular sieve acetate deiodinase adsorber and a preparation method thereof. In the adsorber, the sizes of zeolite cavity openings are respectively 0.66*0.71 nanometers and 0.56*0.56 nanometers, and the adsorber is provided with characteristic X-ray diffraction lines in a BEA (Background Equivalent Activity) type zeolite structure. The deiodinase adsorber is prepared by the steps that saled sodium type zeolite molecular sieve powder with two-dimensional twelve oygen membered ring cavity openings is formed through binder, is in in-situ hydrothermal strengthening treatment to generate chemical bonds and then is treated by ion exchange sodium removal and silver carrying. The adsorber has theadvantages of high crystallization degree, strong particle strength, high silver supported and strong adsorption capacity to organic iodide, inorganic iodide and molecular iodide with different sizescontained in strong acidic medium, can enable the total iodide content in product acetic acid after deiodination treatment by the adsorber to be lower than 5ppb and is suitable for being used as raw materials for synthetizing vinyl acetate.

Owner:FUDAN UNIV +1

Preparation method of antibacterial silver-loaded activated carbon

InactiveCN111908470AIncrease silver loadingGood dispersionCarbon compoundsActivated carbonPhysical chemistry

The invention discloses a preparation method of antibacterial silver-loaded activated carbon, wherein the method comprises the following steps: 1) weighing a certain amount of activated carbon, and soaking in an AgNO3 solution; 2) selecting a deflocculating agent, and dissolving the deflocculating agent in the AgNO3 solution under an ultrasonic condition; 3) slowly dropwise adding a glucose solution into the AgNO3 solution in a stirring state, heating in a water bath, and magnetically stirring; (4) filtering the product obtained in the step (3), washing with water multiple times, removing theredundant glucose until Ag<+> is completely removed, and carrying out vacuum drying; and (5) drying the product obtained in the step (4) in a blast drying oven, and firing in a tubular furnace at a high temperature of 500 DEG C in a nitrogen atmosphere so as to obtain the product.

Owner:YANGZHOU POLYTECHNIC INST

Regeneration and activation technique of iodine pollution solid adsorbent

ActiveCN101380567BImprove distributionIncrease distribution rateDispersed particle separationCombustible gas purificationAcetic acidSorbent

The invention relates to a regeneration and activation technique of solid adsorbent polluted by iodine, which comprises the following steps in sequence: the solid adsorbent polluted by iodine is placed in 0.01 to 1 percent of acetic acid for cleaning; (2) the cleaned adsorbent is soaked in sodium thiosulfate solution with the concentration of 0.01 to 2 percent in static state or placed in a column and the sodium thiosulfate solution with the concentration of 0.01 to 2 percent is injected for regeneration so as to lead the pollutants in effective pore channels of the adsorbent polluted by iodine to be precipitated completely; (3) then the obtained adsorbent is placed in the column and ion exchange is carried out by injecting active metal Ag+ solution till the concentration of the active metal Ag+ on the solid adsorbent reaches the concentration before the solid adsorbent is polluted. The invention has low energy consumption and convenient operation, in particular to the regenerative technique condition that any heating facility is not used, the concentration of the used regenerative liquid is low and can effectively desorb iodine pollutants; the appearance of the activated adsorbent is same as new carriers, is off white, is characterized by high silver-loaded quantity and high adsorption and effectively prolongs the service life of the adsorbent, thus reducing the cost of iodine desorption.

Owner:SHANGHAI HUAYI ENERGY CHEM

A kind of preparation method of silver-loaded activated carbon antibacterial fiber membrane

ActiveCN111910344BIncrease silver loadingGood dispersionElectro-spinningMonocomponent synthetic polymer artificial filamentSpinningNitrogen gas

The invention discloses a preparation method of silver-loaded activated carbon antibacterial fiber membrane, which comprises the following steps: Step 1) Preparation of antibacterial silver-loaded activated carbon: soak activated carbon in AgNO 3 In the solution, choose a deflocculant, dissolve in AgNO 3 solution, and then the glucose solution was slowly added dropwise to the AgNO 3 In the solution, heat it in a water bath and stir it magnetically, then filter the product, wash it with water, and remove glucose until the Ag+ is completely removed, then dry it in vacuum, and finally dry the product in a blast oven, then place it in a tube furnace at a high temperature of 500° in a nitrogen atmosphere Burn to obtain silver-loaded activated carbon; Step 2) Spinning solution preparation: dissolve polyacrylonitrile in a certain volume of N,N-dimethylformamide solution, heat, and magnetically stir to obtain spinning solution, and then Silver activated carbon is added to the spinning liquid, and after sealing, it is magnetically stirred for 8 hours to obtain an antibacterial spinning liquid; Step 3) Spinning: use an electrostatic spinning device for spinning, and the present invention makes the fiber membrane have better antibacterial properties.

Owner:江苏鑫林环保设备有限公司

Antibacterial and pollution-resistant PVDF ultrafiltration membrane for water filtration

ActiveCN107875865BIncrease silver loadingImprove mechanical propertiesMembranesUltrafiltrationUltrafiltrationPolyethylene glycol

The invention discloses an antibacterial and pollution-resistant PVDF ultrafiltration membrane for water filtration, which mainly includes the following components according to parts by mass: polyvinylidene fluoride: 100 parts; polyethylene glycol: 15-35 parts; silver-loaded chitosan : 3‑15 servings. The present invention mixes polyvinylidene fluoride and polyethylene glycol after dissolving in N-methylpyrrolidone solvent through a solution blending method; prepares silver-loaded chitosan solution with chitosan, and dips polyvinylidene fluoride film in The polyvinylidene fluoride microporous membrane with hydrophilic antibacterial and pollution resistance can be prepared after drying in the silver-loaded chitosan solution. The polyvinylidene fluoride microporous membrane prepared by the invention not only has good hydrophilicity, but also can kill microorganisms on the surface, can reduce the amount of protein adhesion in sewage, and can inactivate proteins at the same time, effectively prolonging the life of polyvinylidene fluoride. membrane life.

Owner:河南豫膜环保科技有限公司

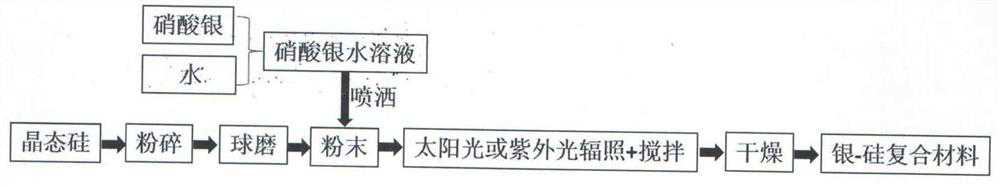

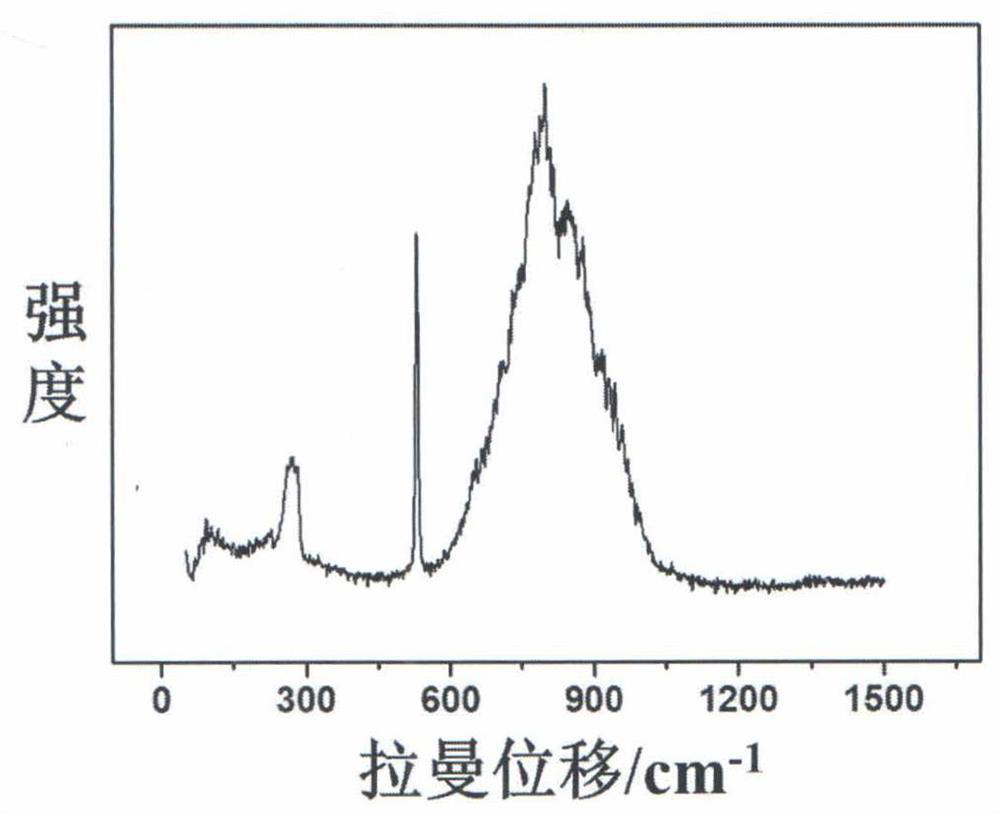

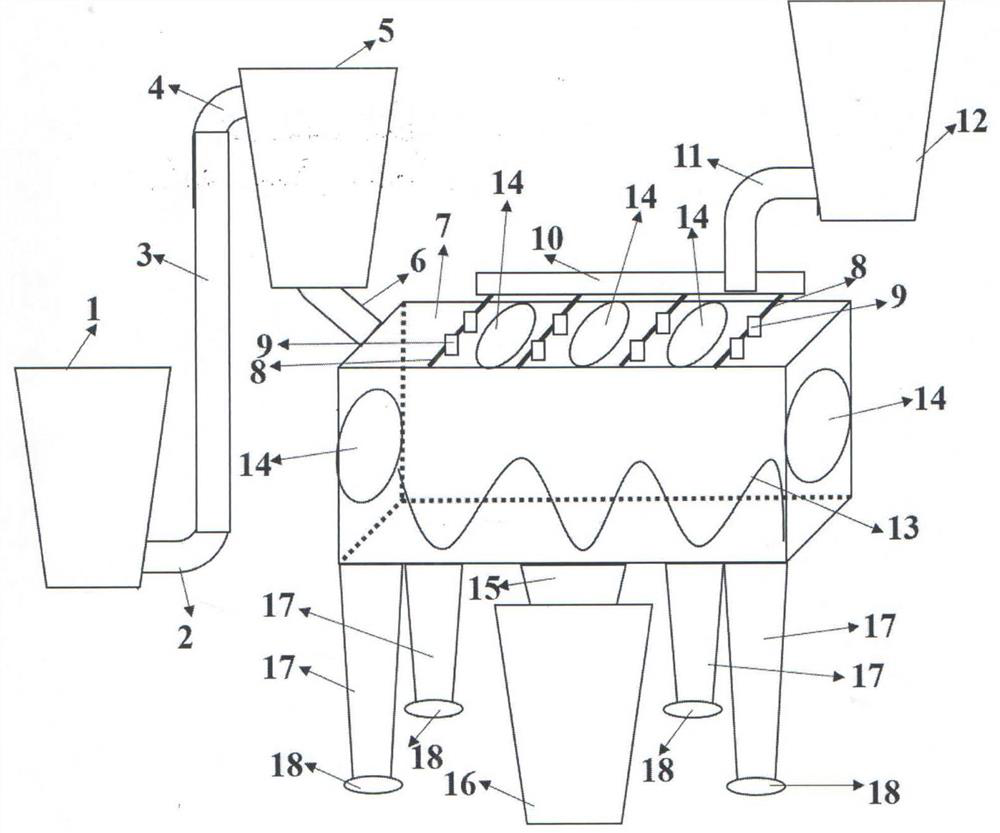

Preparation method and application of silver-silicon antibacterial composite material

InactiveCN112314624AEasy to prepareEasy to operateBiocideDisinfectantsUltraviolet lightsLiquid storage tank

The invention relates to a preparation method of a silver-silicon antibacterial composite material. A device involved in the method is composed of a vacuum feeding machine, a vacuum feeding machine discharging port, a powder conveying pipeline, a transition bin feeding port, a transition bin, a transition bin discharging port, a helical ribbon mixer, a longitudinal solution conveying pipeline, a solution nozzle, a transverse solution conveying pipeline, a solution conveying bent pipe, a liquid storage tank, a light source, a mixer discharging port, a stock bin, a mixer support and moving wheels. Crystalline elemental silicon and silver nitrate are used as raw materials by adopting a dry method or a semi-dry method, the silver nitrate is sprayed on a silicon carrier to obtain semi-dry powder, the semi-dry powder is irradiated by ultraviolet light or sunlight, semiconductor silicon generates electrons and holes under an illumination condition, and the silver nitrate is reduced into the elemental silver after obtaining the electrons, so that the silver-silicon antibacterial composite material is formed. The method has the advantages of simple preparation process, low process energy consumption, no need of adding an additional reducing agent, and no silver ion precipitation. The removal rate of the composite material on escherichia coli, staphylococcus aureus, the total number of bacterial colonies and the like is up to 99%, and the composite material is suitable for large-scale industrial production.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

Antibacterial complete denture and manufacturing method thereof

ActiveCN110384616BImprove antibacterial propertiesImprove toughnessImpression capsDentistry preparationsMedicineEngineering

The invention discloses an antibacterial complete denture and a manufacturing method thereof. An antibacterial complete denture includes artificial teeth and a base, and the base includes the following components in parts by weight: 70-80 parts of tooth base powder, 70-80 parts of tooth base powder, 30-40 parts of supporting water, 2-3 parts of silicon-based toughening agent, 4-8 parts of silver-loaded silica, 2-4 parts of natural antibacterial agent and 1-2 parts of nano-titanium dioxide. The present invention makes the base have excellent antibacterial properties through the compounding of silver-loaded silica, nano-titanium dioxide and natural antibacterial agents, and its compounding with silicon-based toughening agents can further improve the toughness of the base, thereby prolonging its service life .

Owner:杭州拉瓦生物科技有限公司

Preparation method for external-use antibacterial gel used for female vagina

PendingCN110522719AImprove stabilityExtended storage timeAntibacterial agentsInorganic active ingredientsCross-link(Hydroxyethyl)methacrylate

The invention discloses a preparation method for an external-use antibacterial gel used for a female vagina. The preparation method comprises the following steps of: (1) adding a multi-walled carbon nanotube into a sulfuric acid solution to prepare a modified multi-walled carbon nanotube suspension; (2) after N,N-dimethylaminoethyl acrylate, dimethylacrylic acid diethylene glycol ester, hydroxyethyl methylacrylate, the modified multi-walled carbon nanotube suspension, a cross-linking agent and a coagulant are evenly mixed, preparing a precursor solution, preparing a hydrogel after an initiatoris added into the precursor solution, and carrying out freeze drying processing on the hydrogel to obtain a hydrogel dressing; and (3) adding silver nitrate and uridine 5-monophosphate into water, evenly mixing and stirring to obtain an anti-bacterial solution, adding the hydrogel dressing into the anti-bacterial solution, carrying out dipping processing, taking out the hydrogel dressing, cleaning a surface by deionized water, then, adding the hydrogel dressing into a reduction liquid, and carrying out ultrasonic processing to obtain the antibacterial gel. The antibacterial gel prepared by the preparation method disclosed by the invention has the advantages of excellent stability performance and long storage time and also has excellent biocompatibility.

Owner:江苏领驰供应链管理有限公司

A kind of high-efficiency antibacterial fiber and its manufacturing method

ActiveCN110512297BSmall sizeIncrease silver loadingArtificial filament heat treatmentMelt spinning methodsMolecular sieveFiber

The invention discloses a high-efficiency antibacterial fiber and a manufacturing method thereof, which mainly includes three steps of preparing antibacterial masterbatch, antibacterial fiber and antibacterial FDY silk. The present invention utilizes nanoscale silver-loaded molecular sieves with small crystal size, large specific surface area, and high silver loading to prepare high-efficiency antibacterial fibers. The content of antibacterial agents (nanoscale silver-loaded molecular sieves) in the fibers is ≤1‰, and the antibacterial rate is over 99%. After repeated washing, the antibacterial effect did not decrease significantly, and the preparation process of the antibacterial fiber does not require the use of organic solvents. The nano-scale silver-loaded molecular sieves used are prepared by a one-pot method without adding any organic templates. The process is simple, low-cost, and green. ,Environmental friendly.

Owner:MINJIANG UNIV +1

Preparation process of inorganic-organic composite complex antibacterial agent

ActiveCN113498786ASolve poor anti-discoloration abilityAntibacterialBiocideDisinfectantsEngineeringCombinatorial chemistry

The invention discloses a preparation process of an inorganic-organic composite complex antibacterial agent, relates to the technical field of inorganic-organic composite antibacterial agents, and solves the problems of poor discoloration resistance, poor antibacterial durability and poor salt tolerance of a conventional silver ion antibacterial agent through preparation of a complex. The application of the prepared antibacterial agent in light-color products, alkaline environments and products or environments containing chloride ions is successfully realized, the application range of the antibacterial agent is expanded, and the application effect of the antibacterial agent is ensured.

Owner:吉祥三宝高科纺织有限公司

Sea water desalting agent based on silver carrying acid zeolite and its prepn process

InactiveCN1974418BEasy to shapeFast formingSeawater treatmentWater/sewage treatment by ion-exchangeIon exchangeEnvironmental engineering

Owner:TIANJIN SEA WATER DESALINATION & COMPLEX UTILIZATION INST STATE OCEANOGRAPHI

Preparation method of medical stone silver-loaded antibacterial regenerated polyester fiber

PendingCN114134593AImprove antibacterial propertiesAbundant resourcesMonocomponent polyesters artificial filamentArtifical filament manufacturePolyesterPolymer science

The invention discloses a preparation method of medical stone silver-loaded antibacterial regenerated polyester fibers, which comprises the following steps of: independently metering 5-7 percent by weight of dried medical stone silver-loaded antibacterial master batch and 93-95 percent by weight of dried regenerated polyester chips by using an on-line injection machine, uniformly mixing the medical stone silver-loaded antibacterial master batch and the regenerated polyester chips, and uniformly mixing the medical stone silver-loaded antibacterial master batch and the regenerated polyester chips, so as to obtain the medical stone silver-loaded antibacterial regenerated polyester fibers. Stirring and blending, melting and extruding by a screw extruder, spinning by a spinneret plate, cooling by circular blowing, winding and falling into a barrel to obtain a precursor; and carrying out post-spinning drafting, tension heat setting, curling, cutting and packaging on the protofilament to obtain the medical stone silver-loaded antibacterial regenerated polyester fiber. The medical stone silver-loaded antibacterial regenerated polyester fiber has lasting antibacterial ability.

Owner:SHANGHAI DEFULUN CHEM FIBER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com