A kind of preparation method of silver-loaded activated carbon antibacterial fiber membrane

A silver-loaded activated carbon and antibacterial fiber technology, which is applied in the field of fiber membranes, can solve the problems of large specific surface area, poor membrane mechanical properties, and low membrane pressure, and achieve the effects of improving antibacterial performance, good fire resistance, and improving antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

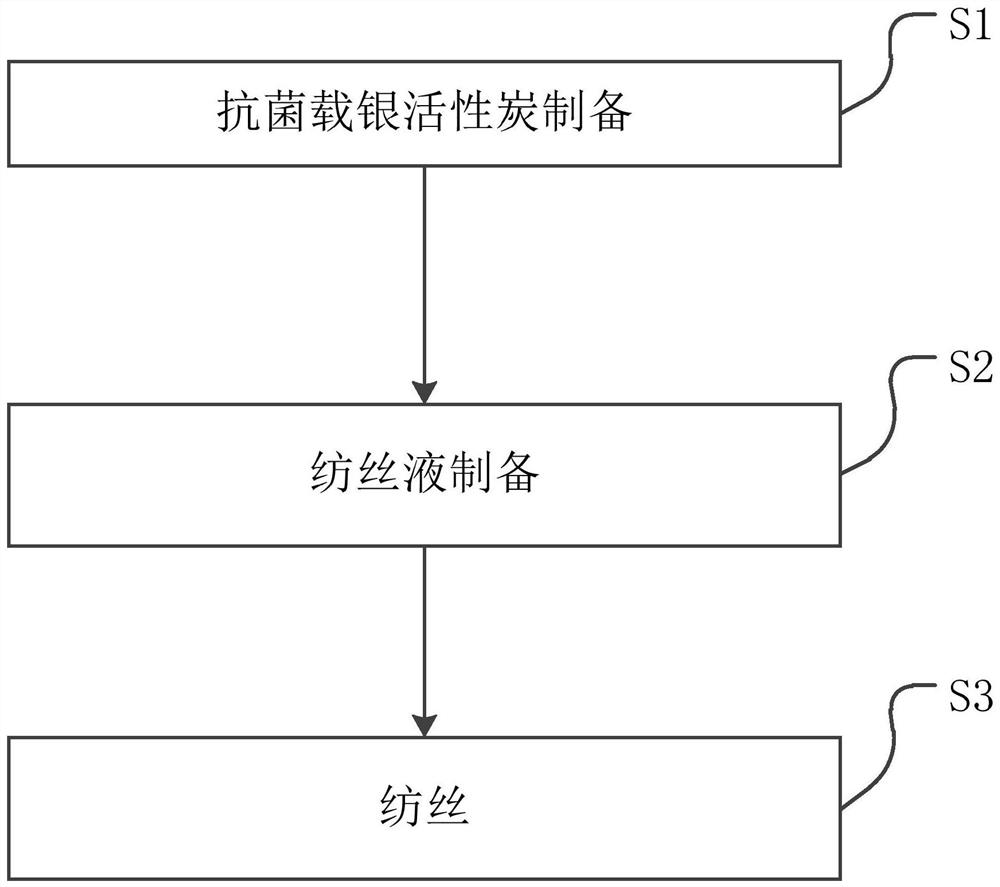

[0019] Such as figure 1 A kind of preparation method of shown antibacterial silver-loaded activated carbon, comprises the following steps:

[0020] Step 1) Preparation of antibacterial silver-loaded activated carbon: Weigh a certain amount of activated carbon and soak it in AgNO with a concentration of 0.08mol / L 3 In the solution; choose phosphate as the anti-flocculation agent, take a certain amount of anti-flocculation agent according to the ratio of anti-flocculation agent: silver ion mass ratio of 0.2:1, dissolve in AgNO under ultrasonic conditions 3 solution; then the glucose solution was slowly added dropwise to the stirred AgNO 3 In the solution, heat in a water bath at 60°C and stir magnetically for 24 hours; filter the product, wash it with water several times to remove excess glucose until Ag+ is completely removed, then dry it in vacuum at 70°C for 8 hours; then dry the product in a blast oven at 70°C for 2 hours , and then burn at high temperature in a nitrogen a...

Embodiment 2

[0024] Such as figure 1 A kind of preparation method of shown antibacterial silver-loaded activated carbon, comprises the following steps:

[0025] Step 1) Preparation of antibacterial silver-loaded activated carbon: Weigh a certain amount of activated carbon and soak it in AgNO with a concentration of 0.08mol / L 3 In the solution; choose phosphate as the anti-flocculation agent, take a certain amount of anti-flocculation agent according to the ratio of anti-flocculation agent: silver ion mass ratio of 0.5:1, dissolve in AgNO under ultrasonic conditions 3 solution; then the glucose solution was slowly added dropwise to the stirred AgNO 3 In the solution, heat in a water bath at 60°C and stir magnetically for 24 hours; filter the product, wash it with water several times to remove excess glucose until Ag+ is completely removed, then dry it in vacuum at 70°C for 8 hours; then dry the product in a blast oven at 70°C for 2 hours , and then burn at high temperature in a nitrogen a...

Embodiment 3

[0029] Such as figure 1 A kind of preparation method of shown antibacterial silver-loaded activated carbon, comprises the following steps:

[0030] Step 1) Preparation of antibacterial silver-loaded activated carbon: Weigh a certain amount of activated carbon and soak it in AgNO with a concentration of 0.08mol / L 3 In the solution; choose phosphate as the anti-flocculation agent, take a certain amount of anti-flocculation agent according to the ratio of anti-flocculation agent: silver ion mass ratio of 1:1, and dissolve it in AgNO under ultrasonic conditions. 3 solution; then the glucose solution was slowly added dropwise to the stirred AgNO 3 In the solution, heat in a water bath at 60°C and stir magnetically for 24 hours; filter the product, wash it with water several times to remove excess glucose until Ag+ is completely removed, then dry it in vacuum at 70°C for 8 hours; then dry the product in a blast oven at 70°C for 2 hours , and then burn at high temperature in a nitr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com