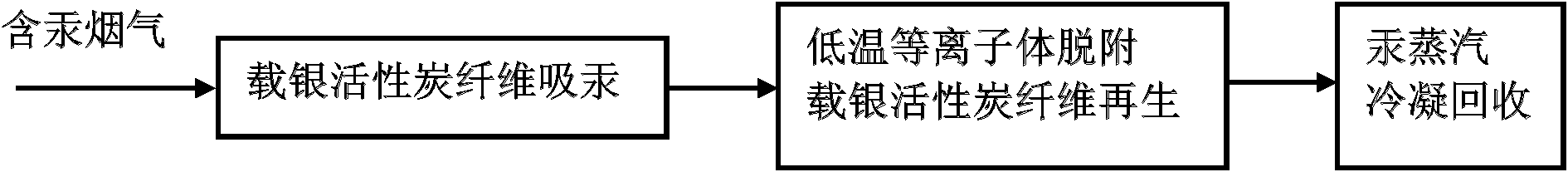

Method for purifying and recycling mercury in flue gas

A recovery method and flue gas technology, applied in combustible gas purification, chemical instruments and methods, combustible gas purification/transformation, etc., can solve the problems of repeated recycling of adsorbents, slow desorption speed, and low desorption rate , to achieve the effect of improving desorption regeneration performance, improving adsorption performance, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0047] (1) Soak the activated carbon fiber in a phosphoric acid solution with a mass fraction of 15% for 12 hours, then take it out and dry it for later use.

[0048] (2) Place the dried activated carbon fibers in a low-temperature plasma reactor, use nitrogen as a protective gas at 25°C, apply a voltage of 30kV, activate with low-temperature plasma for 30min, and then stop powering on.

[0049] (3) The specific surface area of activated carbon fiber before and after activation is 1200 and 1450m respectively 2 / g.

[0050] (4) The activated activated carbon fibers were soaked and cleaned with deionized water to remove residual acid and other substances, and then put into an oven and dried at 105° C. for 2 hours.

[0051] (5) Prepare 500 mL of silver nitrate solutions with mass concentrations of 0.1, 0.2, 0.3 and 0.5 mg / mL by constant volume method, and place them in brown glass bottles for sealed storage. Weigh 4g ACF (specific surface area is about 1000m 2 / g of viscose-...

specific Embodiment 2

[0071] (1) Soak the activated carbon fiber in a phosphoric acid solution with a mass fraction of 35% for 12 hours, then take it out and dry it for later use.

[0072] (2) Place the dried activated carbon fibers in a low-temperature plasma reactor, use nitrogen as a protective gas at 25°C, apply a voltage of 30kV, activate with low-temperature plasma for 30min, and then stop powering on.

[0073] (3) The specific surface area of activated carbon fiber before and after activation is 1200 and 1500m 2 / g.

[0074] (4) The activated activated carbon fibers were soaked and cleaned with deionized water to remove residual acid and other substances, and then put into an oven and dried at 105° C. for 2 hours.

[0075] (5) Prepare 500 mL of silver nitrate solutions with mass concentrations of 0.1, 0.2, 0.3 and 0.5 mg / mL by constant volume method, and place them in brown glass bottles for sealed storage. Weigh 4g ACF (specific surface area is about 1000m 2 / g of viscose-based activat...

specific Embodiment 3

[0088] (1) Soak the activated carbon fiber in a phosphoric acid solution with a mass fraction of 35% for 24 hours, then take it out and dry it for later use.

[0089] (2) Place the dried activated carbon fibers in a low-temperature plasma reactor, use nitrogen as a protective gas at 25°C, apply a voltage of 30kV, activate with low-temperature plasma for 30min, and then stop powering on.

[0090] (3) The specific surface area of activated carbon fiber before and after activation is 1200 and 1550m respectively 2 / g.

[0091] (4) The activated activated carbon fibers were soaked and cleaned with deionized water to remove residual acid and other substances, and then put into an oven and dried at 105° C. for 2 hours.

[0092] (5) Prepare 500 mL of silver nitrate solutions with mass concentrations of 0.1, 0.2, 0.3 and 0.5 mg / mL by constant volume method, and place them in brown glass bottles for sealed storage. Weigh 4g ACF (specific surface area is about 1000m 2 / g of viscose-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com