Method for plating silver on surface of carbon material

A carbon material and silver-plating technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as complex process flow, low reaction efficiency, uneven coating, etc., and achieve simple process and low residue The effect of low content and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

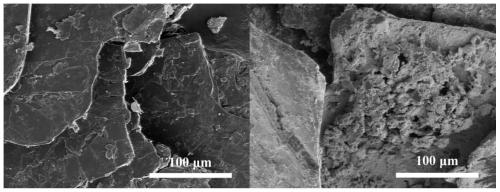

[0039] Embodiment 1 graphite flake silver plating method

[0040] (1) Modification of graphite flakes: 1 g of polyvinylpyrrolidone was added to 49 g of deionized water, and after stirring for 10 minutes, 5 g of graphite flake powder was added and stirred for 30 minutes at a stirring rate of 400 rpm / min.

[0041] (2) Impregnation and drying of graphite flakes: Dissolve 5g of silver nitrate in 45g of deionized water, then add it to the mixed solution prepared in step (1), stir for 4h at a stirring rate of 400rpm / min, then place in a light-proof environment freeze-dried to constant weight.

[0042] (3) Calcination and reduction: place the impregnated and dried graphite flake powder in a corundum crucible, put it into a tube furnace, and heat up and calcinate for reduction in an argon atmosphere. The heating rate is 10°C / min, and the calcination temperature is 500°C. , heat preservation for 30min, to obtain silver-coated graphite flake powder.

[0043] The silver content of the ...

Embodiment 2

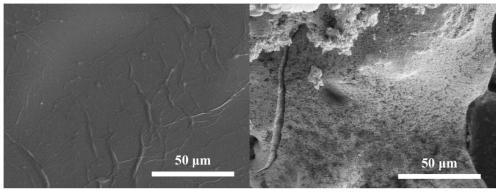

[0044] Embodiment 2 graphene oxide silver plating method

[0045] (1) Modification of graphene oxide: 1g maleic anhydride grafted polypropylene emulsion was added to 49g deionized water, after stirring for 10min, 100mL graphene oxide solution was added, the concentration of graphene oxide solution was 5g / L, Stir for 30 min at a stirring rate of 400 rpm / min.

[0046](2) Impregnation and drying of graphene oxide: Dissolve 3g of silver nitrate in 47g of deionized water, then add it to the mixed solution configured in step (1), stir for 4h at a stirring rate of 400rpm / min, and then place it in the dark Stir and heat up in the environment and dry to constant weight, the drying temperature is 60°C.

[0047] (3) Calcination and reduction: place the impregnated and dried carbon fiber powder in a corundum crucible, put it into a tube furnace, and heat up and calcined for reduction in an argon atmosphere. The heating rate is 10°C / min, and the calcination temperature is 1000°C. Insulat...

Embodiment 3

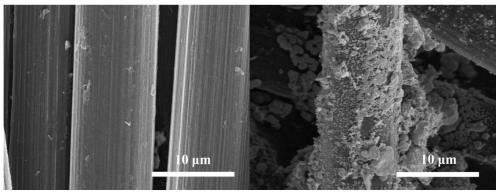

[0049] Embodiment 3 carbon fiber silver plating method

[0050] (1) Modification of carbon fiber: Add 1 g of polyvinyl alcohol solution into 49 g of deionized water, and after stirring for 10 min, add 5 g of carbon fiber powder, and stir for 30 min at a stirring speed of 400 rpm / min.

[0051] (2) Impregnation and drying of carbon fiber: Dissolve 10g of silver nitrate in 40g of deionized water, then add it to the mixed solution prepared in step (1), stir for 4h at a stirring rate of 400rpm / min, and then place it in a light-proof environment Heat up and stir to dry to constant weight, the drying temperature is 60°C.

[0052] (3) Calcination and reduction: place the impregnated and dried carbon fiber powder in a corundum crucible, put it into a tube furnace, and heat up and calcinate and reduce in an argon atmosphere. The heating rate is 10°C / min, and the calcination temperature is 500°C. Insulated for 30 minutes to obtain silver-plated carbon fiber powder.

[0053] The silver ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com