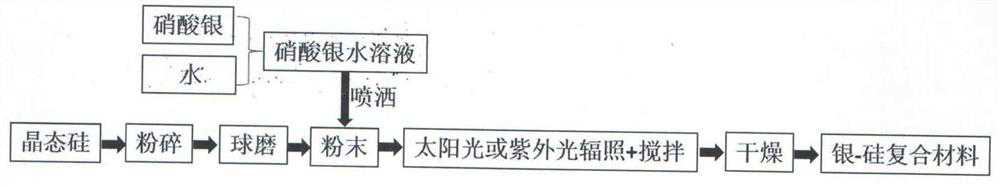

Preparation method and application of silver-silicon antibacterial composite material

A technology of composite materials and silicon powder, which is applied in the field of preparation of silver-silicon antibacterial composite materials, can solve the problems of low loading, complex synthesis process, nano-silver falling off, etc., achieve high stability and safety, and no additional pollutants , the effect of simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

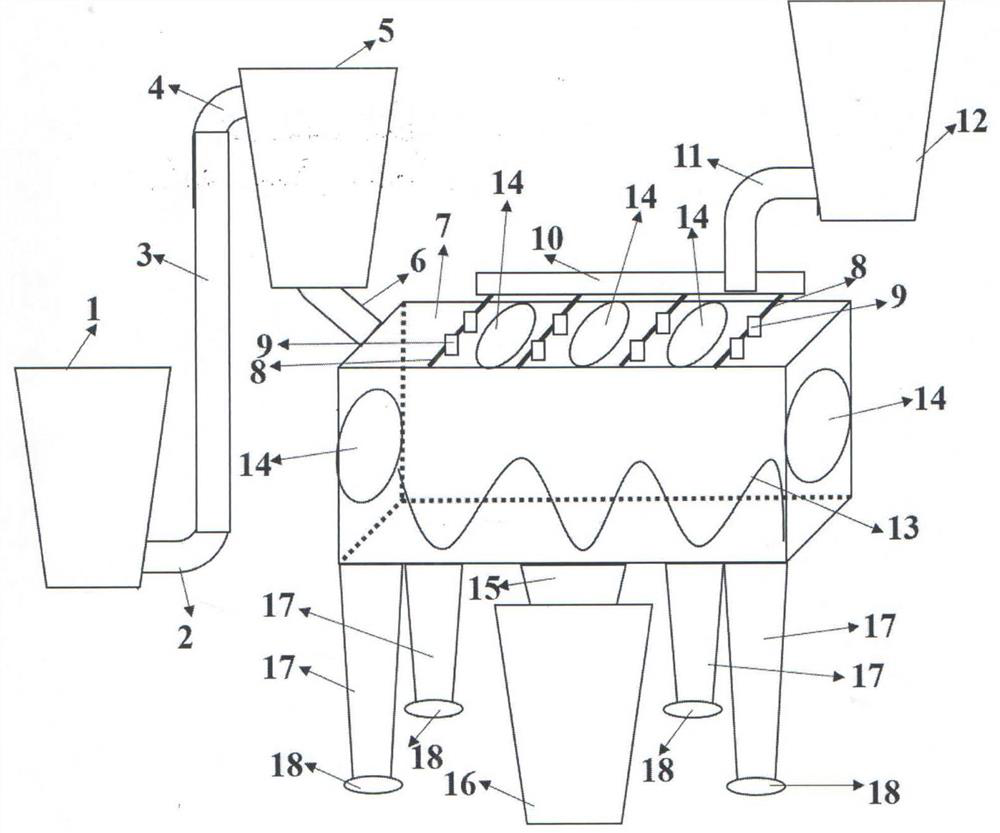

[0021] The preparation method of a kind of silver-silicon antibacterial composite material of the present invention, the device that this method involves is by vacuum feeder 1, vacuum feeder outlet 2, powder conveying pipeline 3, transition bin feed inlet 4 , transition chamber 5, transition chamber outlet 6, ribbon mixer 7, longitudinal solution delivery pipeline 8, solution nozzle 9, horizontal solution delivery pipeline 10, solution delivery elbow 11, liquid storage tank 12, ribbon 13, Composed of ultraviolet light source and simulated solar light source 14, mixer outlet 15, silo 16, mixer bracket 17, and moving wheel 18, the bottom of vacuum feeder 1 is provided with vacuum feeder outlet 2, vacuum The discharge port 2 of the feeder is connected to one end of the powder conveying pipeline 3, and the other end of the powder conveying pipeline 3 is connected to the feed port 4 of the transition chamber. The feed port 4 of the transition chamber is located at the top of the tra...

Embodiment 2

[0029] The device involved in the method is carried out according to Example 1, and the specific operation is carried out according to the following steps:

[0030] Preparation of monocrystalline silicon powder:

[0031] a. After crushing 5 kg of single crystal silicon with a particle size of 1 cm, use a ball mill to mill for 36 hours, and sieve through 200 mesh to obtain silicon powder;

[0032] To prepare silver nitrate solution:

[0033] B, by weight, the silver nitrate of 0.04kg is dissolved in 2kg water and dissolves to obtain silver nitrate aqueous solution;

[0034] Synthetic silver-silicon composite:

[0035]c. Put 5 kg of monocrystalline silicon powder ground in step a into the vacuum feeder 1, and pass through the vacuum feeder outlet 2, the powder conveying pipeline 3, the transition chamber feed port 4, the transition chamber 5 and the transition chamber The discharge port 6 is transported to the ribbon mixer 7, and then the stirring ribbon 13 is opened, so that...

Embodiment 3

[0037] The device involved in the method is carried out according to Example 1, and the specific operation is carried out according to the following steps:

[0038] Preparation of monocrystalline silicon powder:

[0039] a. After crushing 5 kg of monocrystalline silicon with a particle size of 2 cm, ball mill it with a ball mill for 48 hours, and sieve through 150 mesh to obtain silicon powder;

[0040] To prepare silver nitrate solution:

[0041] B, the silver nitrate of 0.08kg is dissolved in 2kg water by weight and dissolves to obtain silver nitrate aqueous solution;

[0042] Synthetic silver-silicon composite:

[0043] c. Put 5 kg of monocrystalline silicon powder ground in step a into the vacuum feeder 1, and pass through the vacuum feeder outlet 2, the powder conveying pipeline 3, the transition chamber feed port 4, the transition chamber 5 and the transition chamber The discharge port 6 is transported to the ribbon mixer 7, and the stirring ribbon 13 is turned on, so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com