High-efficiency antibacterial fiber and manufacturing method thereof

An antibacterial fiber and a manufacturing method technology, applied in the field of textile fibers, can solve the problems of low silver loading, complicated preparation conditions of micron-level silver loading molecular sieves, etc., and achieve the effects of efficient antibacterial effect, high silver loading and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

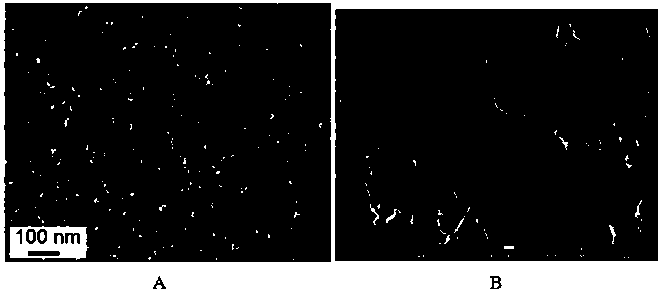

[0031] Example 1 Manufacture of a high-efficiency antibacterial polyester fiber

[0032] (1) Preparation of nanoscale silver-loaded molecular sieves: at room temperature, in beaker A, dissolve 7g of sodium hydroxide in 25g of deionized water, then add 0.5g of aluminum powder, and stir until the aluminum powder is completely dissolved; in beaker B, Dissolve 4g of sodium hydroxide in 25g of deionized water, then add 35g of silica sol, and stir until the solution becomes clear; under stirring conditions, add the solution in beaker A to beaker B dropwise, and then add 0.2g of AgNO 3 , after continuing to stir for 24 hours, transfer to an oven at 80°C for crystallization for 1 day, centrifuge at 20,000r / min, wash with water to pH 8~9, dry to obtain sample powder, and set aside; the prepared silver-loaded molecular sieve has a specific surface area of 780m 2 / g; the size range of particle size is 40~50nm; the pore size mainly includes micropore and mesopore. ;

[0033] (2) Prepa...

Embodiment 2

[0037] Example 2 Manufacture of a high-efficiency antibacterial nylon fiber

[0038](1) Preparation of nanoscale silver-loaded molecular sieves: at room temperature, in beaker A, dissolve 7g of sodium hydroxide in 25g of deionized water, then add 0.5g of aluminum powder, and stir until the aluminum powder is completely dissolved; in beaker B, Dissolve 4g of sodium hydroxide in 25g of deionized water, then add 50g of silica sol, and stir until the solution becomes clear; under stirring conditions, add the solution in beaker A to beaker B dropwise, and then add 0.2g of AgNO 3 , continue stirring for 24 hours, transfer to an oven at 80°C for crystallization for 1 day, centrifuge at 20,000r / min, wash with water to pH 8~9, dry to obtain sample powder, and set aside; the prepared silver-loaded molecular sieve has a specific surface area of 760m 2 / g; the size range of particle size is 40~50nm; the pore size mainly includes micropore and mesopore. ;

[0039] (2) Preparation of an...

Embodiment 3

[0043] Example 3 Manufacture of a high-efficiency antibacterial polypropylene fiber

[0044] (1) Preparation of nanoscale silver-loaded molecular sieves: at room temperature, in beaker A, dissolve 7g of sodium hydroxide in 25g of deionized water, then add 0.5g of aluminum powder, and stir until the aluminum powder is completely dissolved; in beaker B, Dissolve 4g of sodium hydroxide in 25g of deionized water, then add 65g of silica sol, and stir until the solution becomes clear; under stirring conditions, add the solution in beaker A to beaker B dropwise, and then add 0.2g of AgNO 3 , continue to stir for 24 hours, transfer to an oven at 80°C for crystallization for 1 day, centrifuge at 20,000r / min, wash with water to pH 8~9, dry to obtain sample powder, and set aside; the prepared silver-loaded molecular sieve has a specific surface area of 720m 2 / g; the size range of particle size is 40~50nm; the pore size mainly includes micropore and mesopore. ;

[0045] (2) Preparati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com