High nanometer sliver loading active carbon and preparation method thereof

A nano-silver activated carbon, high-load technology, applied in botanical equipment and methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of limited adsorption capacity, influence on silver loading, limited effect, etc., to achieve uniform distribution, The effect of contributing to quality control and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

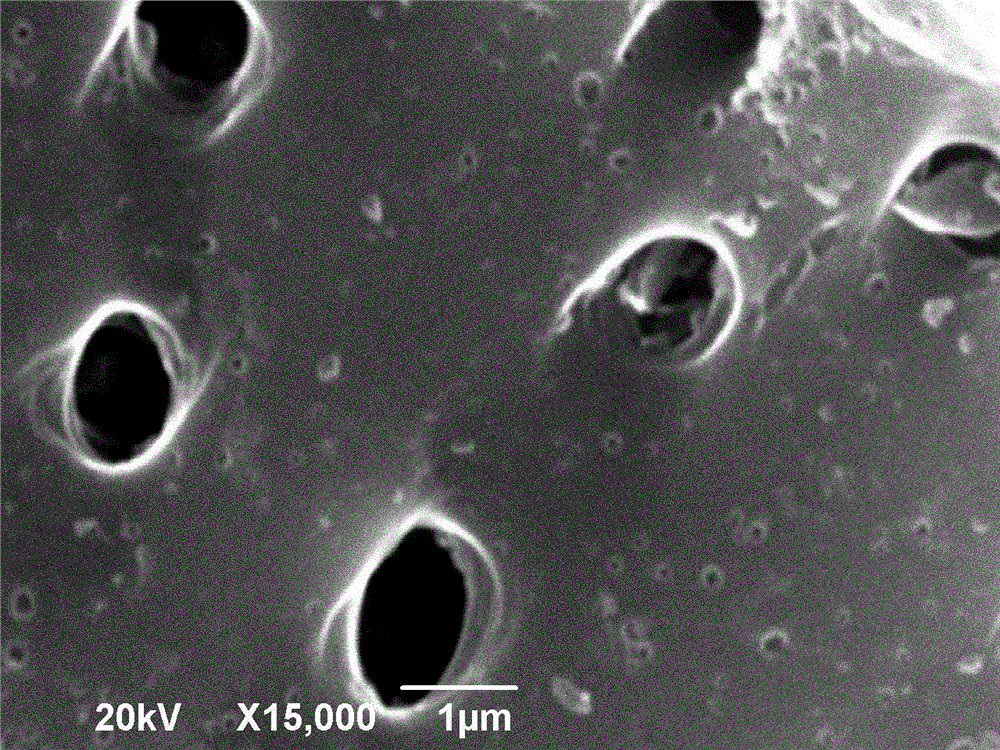

[0040] This example relates to a preparation method of nano-silver-loaded coconut shell activated carbon loaded with nano-silver particles (20nm)

[0041] Take 1 kg of freshly prepared fragmented coconut shell activated carbon, grind it through an 80-mesh sieve, wash it with 5 kg of pure water for several times until the lotion is clear and colorless; Cool to room temperature, and record it as coconut shell activated carbon AC-0; under 180rpm stirring, add 1 kg of the above coconut shell activated carbon to 30% hydrogen peroxide, keep stirring at room temperature for 5-8 hours, and filter out the activated carbon; 5 kg of pure water repeatedly Pump and wash until the lotion is colorless and neutral, at this time, the conductivity of the lotion is lower than 20.0μs / cm; dry the modified coconut shell activated carbon at 100-140°C to constant weight, and cool it in a desiccator To room temperature, recorded as coconut shell activated carbon AC-1.

[0042] In an environment of 40...

Embodiment 2

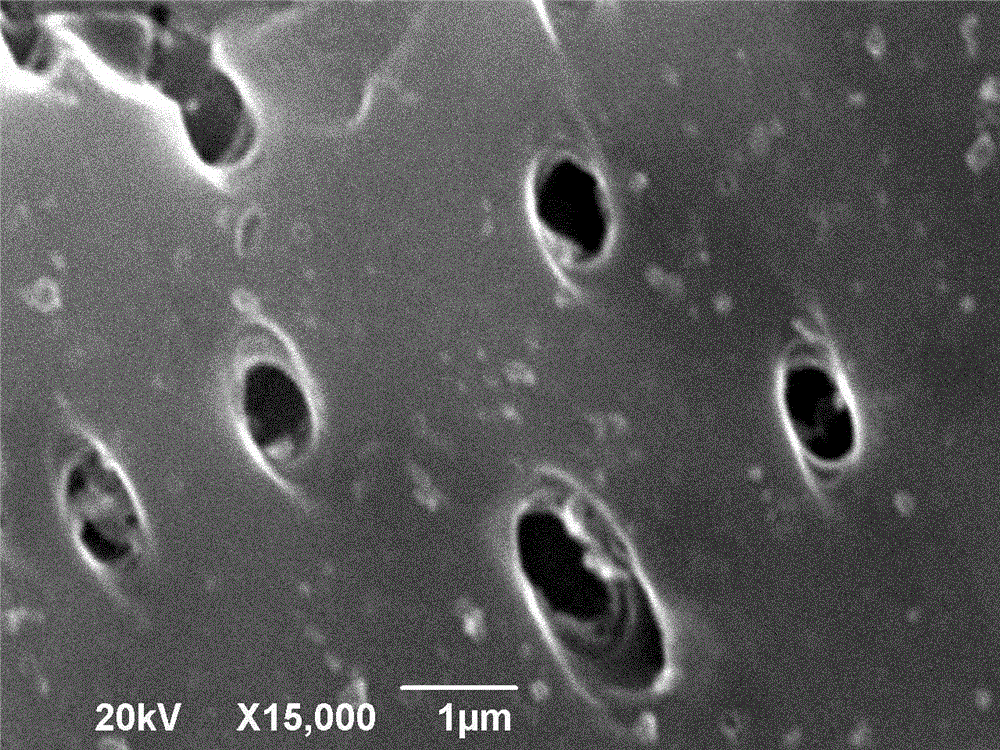

[0046] This example relates to a preparation method of nano-silver-loaded coconut shell activated carbon loaded with nano-silver particles (30nm)

[0047] Take 1 kg of freshly prepared fragmented coconut shell activated carbon, grind it and pass it through a 50-mesh sieve, wash it with 3-5 kg of pure water for several times until the lotion is clear and colorless; dry it at 100-150 °C to constant weight, Cool to room temperature in a desiccator, record as coconut shell activated carbon AC-0; under stirring at 150rpm, add 1 kg of the above coconut shell activated carbon to 30% hydrogen peroxide, keep stirring at room temperature overnight (12h), filter out activated carbon; 5 kg of pure water Repeated pumping and washing until the lotion is colorless and neutral, at this time, the conductivity of the lotion is lower than 20.0μs / cm; the modified coconut shell activated carbon is dried at 100~150°C to constant weight, and placed in a desiccator Cool down to room temperature, re...

Embodiment 3

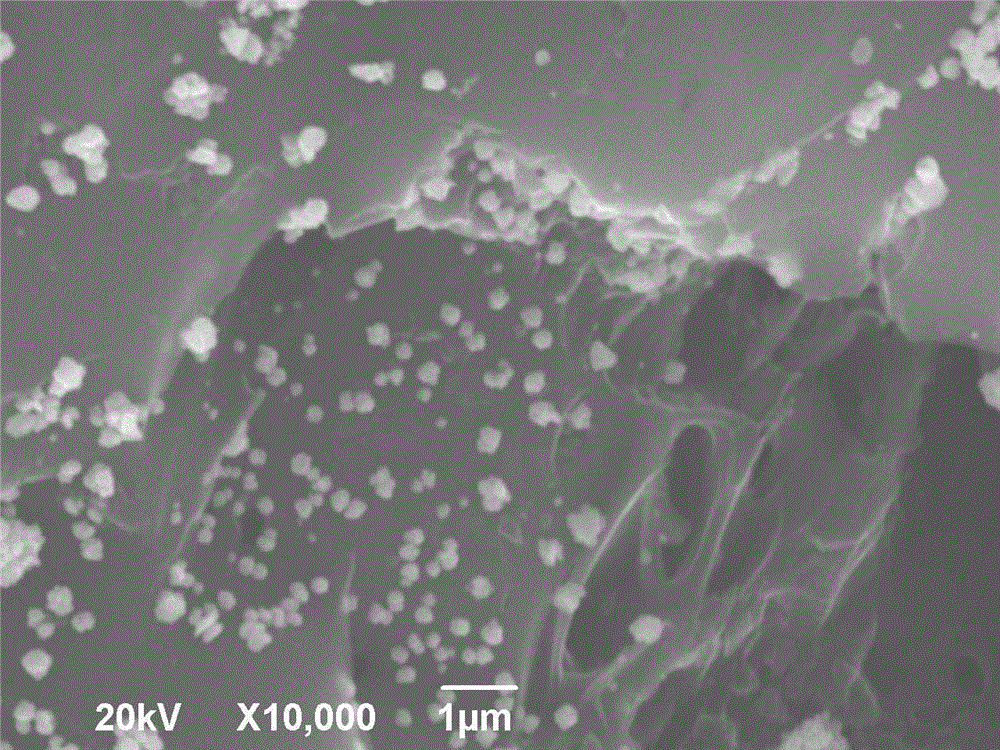

[0052] This example relates to a preparation method of nano-silver loaded walnut shell activated carbon loaded with nano-silver particles (50nm)

[0053] Take 5 kg of freshly prepared fragmented walnut shell activated carbon, grind it through a 30-mesh sieve, wash it with 20 kg of pure water for several times until the lotion is clear and colorless; dry it at 120°C to constant weight, and cool it in a desiccator To room temperature, record as walnut shell activated carbon AC-0; under 180rpm stirring, add 1 kg of the above walnut shell activated carbon into 15~20% nitric acid aqueous solution, soak at room temperature for 4 hours, filter out activated carbon; 25 kg of pure water repeatedly pump and wash Until the lotion is colorless and neutral, at this time the conductivity of the lotion is lower than 20.0 μs / cm; dry the walnut shell activated carbon activated by nitric acid at 120°C to constant weight, cool it to room temperature in a desiccator, and record Make Walnut Shell ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com