Antibacterial complete denture and manufacturing method thereof

A technology of complete dentures and natural antibacterial agents, applied in the field of denture materials, can solve the problems of reducing the service life of dentures, easy to produce oral inflammation, and easy formation of plaque on dentures, etc., and achieves long service life, excellent toughening effect, and relieve nausea. effect of vomiting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

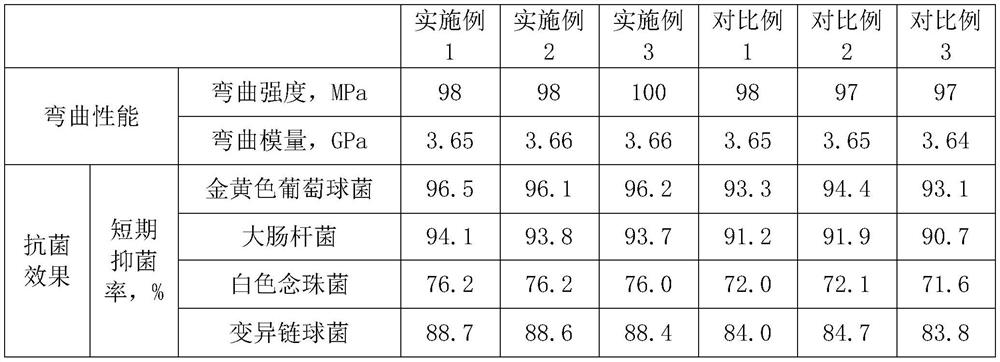

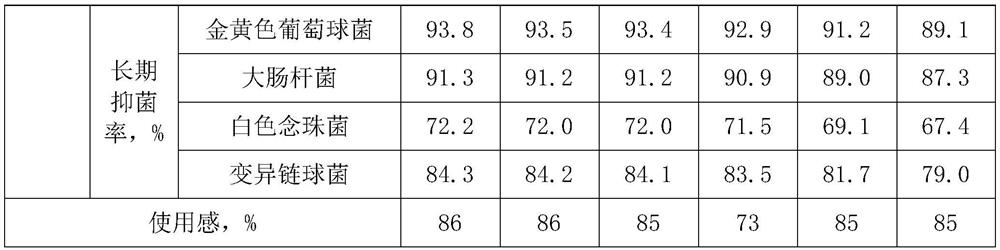

Examples

preparation example 1

[0037] Preparation example 1: ① Take 20kg of silicon dioxide, 1kg of titanium dioxide and 0.6kg of zirconium dioxide, grind them, place them at a temperature of 900°C, and calcinate them for 4 hours. After cooling, a calcined material is obtained;

[0038] ②Take 0.2kg of silver nitrate powder, add 30kg of water to it, and stir evenly to obtain a silver nitrate solution; add 2kg of calcined material to the silver nitrate solution, and stir at a temperature of 20-30°C for 10 minutes to obtain a mixed solution;

[0039] ③Add 0.2kg of glucose and 1kg of 10wt% sodium hydroxide aqueous solution to the mixed solution, stir for 10min, filter with suction, then wash with 50wt% ethanol solution, and dry at 80°C for 6h to obtain silver-loaded silica.

preparation example 2

[0040] Preparation Example 2: ① Take 25kg of silicon dioxide, 1.5kg of titanium dioxide and 0.8kg of zirconium dioxide, grind them, place them at a temperature of 925°C, and calcinate them for 5 hours. After cooling, a calcined material is obtained;

[0041] ②Take 0.25 kg of silver nitrate powder, add 30 kg of water to it, and stir evenly to obtain a silver nitrate solution; add 3 kg of calcined material to the silver nitrate solution, and stir for 15 minutes at a temperature of 25°C to obtain a mixed solution;

[0042] ③Add 0.3kg of glucose and 1.5kg of 10wt% sodium hydroxide aqueous solution to the mixed solution, stir for 15min, filter with suction, then wash with 50wt% ethanol solution, and dry at 85°C for 7h to obtain the Silver silica.

preparation example 3

[0043]Preparation example 3: ① Take 30kg of silicon dioxide, 2kg of titanium dioxide and 1kg of zirconium dioxide, grind them, place them at a temperature of 950°C, and calcinate them for 6 hours. After cooling, a calcined material is obtained;

[0044] ② Take 0.3 kg of silver nitrate powder, add 30 kg of water to it, and stir evenly to obtain a silver nitrate solution; add 4 kg of calcined material to the silver nitrate solution, and stir for 20 minutes at a temperature of 30°C to obtain a mixed solution;

[0045] ③Add 0.4kg of glucose and 2kg of 10wt% sodium hydroxide aqueous solution to the mixed solution, stir for 20min, filter with suction, then wash with 50wt% ethanol solution, and dry at 90°C for 8h to obtain silver-loaded silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com