Process for production of water-absorbable resin particle, and water-absorbable resin particle produced by the process

一种树脂粒子、吸水性的技术,应用在吸水性树脂粒子的制备领域,能够解决不能充分满足吸水容量等问题,达到优良吸水容量、窄粒度分布、高粒子强度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Prepare a cylindrical type with an inner diameter of 100 mm equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring paddle (a two-stage four-pitched paddle blade with a blade diameter of 50 mm) as a stirrer. Round bottom detachable flask. Add 500 ml of n-heptane, 0.92 g of sucrose stearate (Mitsubishi Chemical F-Z (KK), Ryoto sucrose ester S-370) of HLB 3, and maleic anhydride-modified ethylene-propylene copolymer ( Mitsui Chemicals Co., Ltd., Hi-wax 1105A) 0.92 g, heated up to 80° C. to dissolve the dispersion stabilizer, and then cooled to 50° C.

[0071] On the other hand, 92 g of an 80.5% by mass acrylic acid aqueous solution was added to a 500 ml Erlenmeyer flask, and while cooling from the outside, 154.1 g of a 20.0% by mass sodium hydroxide aqueous solution was added dropwise to neutralize 75% by mole of acrylic acid, and the persulfuric acid 0.11 g of potassium and 9.2 mg of N,N'-methylenebisacrylamide were added an...

Embodiment 2

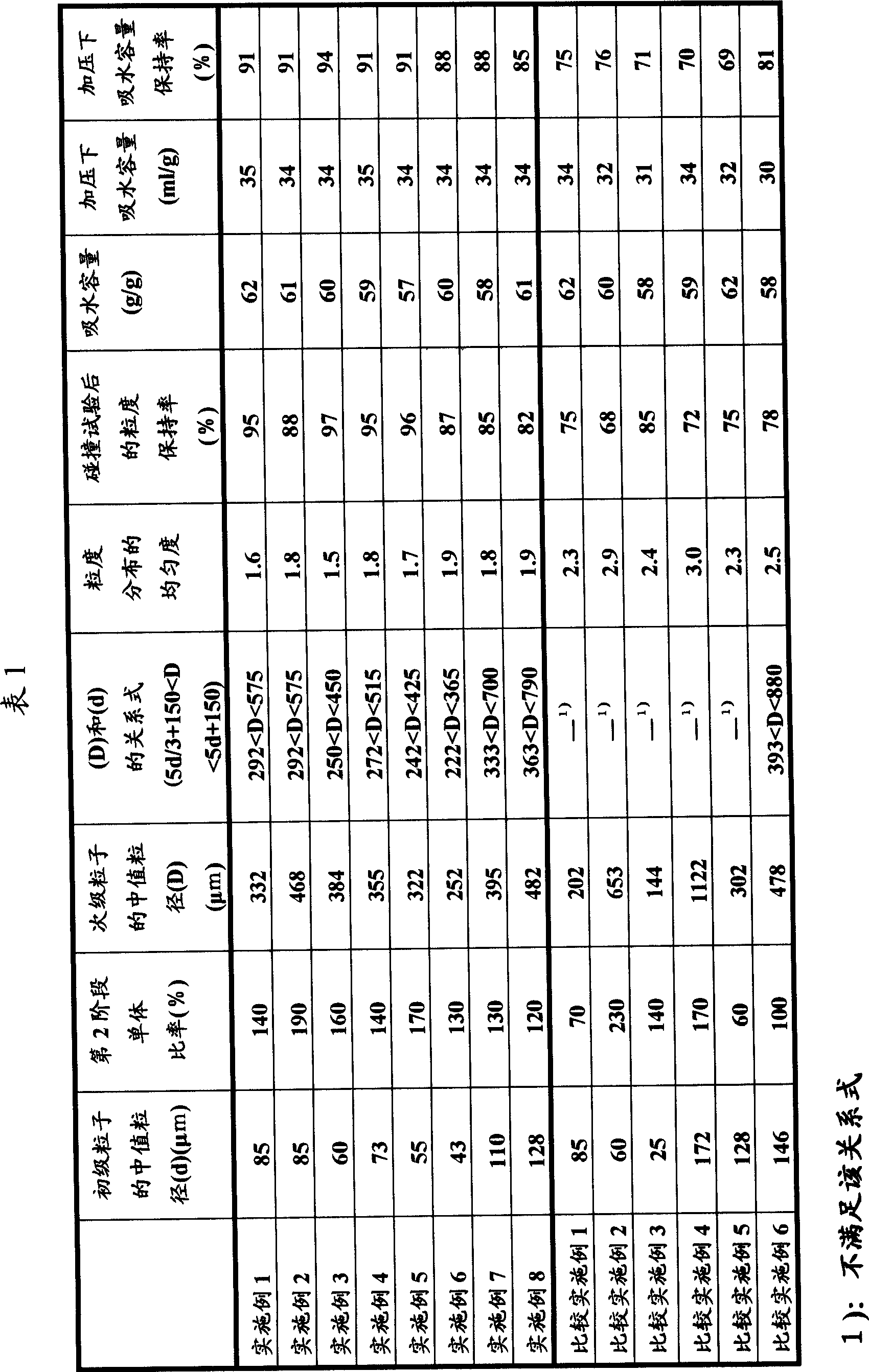

[0078] 278.8 g of water-absorbent resin particles in the form of agglomerated spherical particles were obtained in the same manner as in Example 1, except that the composition of the monomer aqueous solution in the second-stage polymerization in Example 1 was changed to 80.5% by mass. 174.8 g of acrylic acid aqueous solution, 237.4 g of 24.7% by mass sodium hydroxide aqueous solution, 0.21 g of potassium persulfate, and 17.5 mg of N,N'-methylenebisacrylamide were further dehydrated by n-heptane reflux after the second-stage polymerization. The amount was 313.9 g, and the amount of a 2% aqueous solution of ethylene glycol diglycidyl ether after dehydration was 10.7 g. The median diameter of the secondary particles was 468 μm, and the water content was 5.6%. Table 1 shows the measurement results of each property.

Embodiment 3

[0080] Prepare a detachable cylindrical type with an inner diameter of 100mm equipped with a reflux condenser, a dropping funnel, a nitrogen gas introduction pipe, and a stirring paddle (two-stage 4-blade flat paddle with a paddle diameter of 50mm) as a stirrer. flask. Add 500 ml of n-heptane, 0.92 g of sucrose stearate of HLB 3 (Mitsubishi Chemical F-Z (KK), Ryoto sucrose ester S-370), maleic anhydride modified ethylene-propylene copolymer ( Mitsui Chemicals Co., Ltd., Hi-wax 1105A) 0.92g, heated up to 80°C to dissolve the dispersion stabilizer, and then cooled to 50°C.

[0081] On the other hand, 92 g of an 80.5% by mass acrylic acid aqueous solution was added to a 500 ml Erlenmeyer flask, and while cooling from the outside, 154.1 g of a 20.0% by mass sodium hydroxide aqueous solution was added dropwise to neutralize 75% by mole of acrylic acid, and the persulfuric acid 0.11 g of potassium and 9.2 mg of N,N'-methylenebisacrylamide were added and dissolved to prepare the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com