Particulate attapulgite adsorbent and preparation method thereof

A technology of granular attapulgite and attapulgite, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve the problems of increasing the adsorption performance of organic pollution, easy dissolution of surfactants, secondary pollution, etc. problems, to achieve the effect of easy settlement, cheap raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

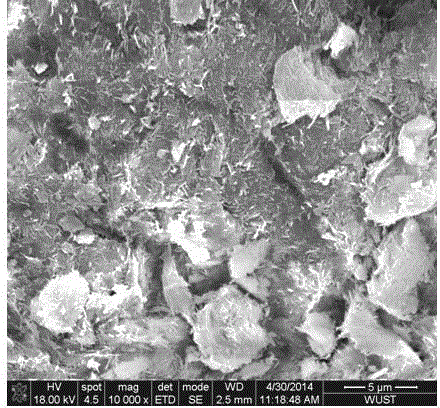

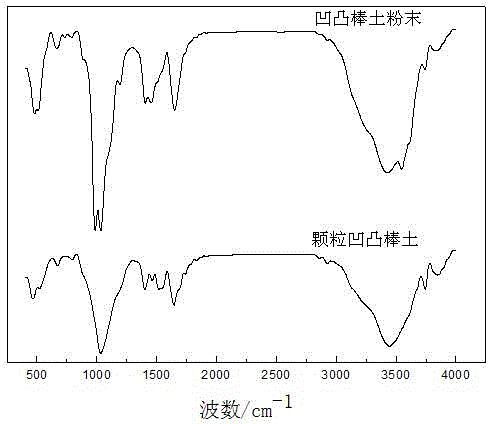

Image

Examples

Embodiment 1

[0022] A granular attapulgite adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0023] Step 1, mixing water and attapulgite powder evenly, the mass ratio of water and attapulgite powder is 1: 0.5~0.7, to obtain muddy attapulgite;

[0024] Step 2, drying the prepared mud-like attapulgite at 90-100° C. for 12-16 hours, and breaking it into granular attapulgite with a particle size of 0.45-1.25 mm;

[0025] Step 3, then place the prepared granular attapulgite in a muffle furnace, and calcinate at 650-700° C. for 2.5-3 hours to prepare the granular attapulgite adsorbent.

[0026] It is 20mg / L containing Pb with the attapulgite adsorbent that the present embodiment 1 makes to concentration 2+ The wastewater is subjected to adsorption treatment. Under the conditions that the dosage of the granular attapulgite adsorbent is 1g / L, the stirring speed of 250r / min and the adsorption time are 2h, the Pb-containing 2+ Pb in wastewater 2+ The...

Embodiment 2

[0028] A granular attapulgite adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0029] Step 1, mixing water and attapulgite powder evenly, the mass ratio of water and attapulgite powder is 1:0.6~0.8, to obtain muddy attapulgite;

[0030] Step 2, drying the prepared mud-like attapulgite at 90-100° C. for 12-16 hours, and breaking it into granular attapulgite with a particle size of 0.45-1.25 mm;

[0031] Step 3, then place the prepared granular attapulgite in a muffle furnace, and calcinate at 650-700° C. for 2.5-3 hours to prepare the granular attapulgite adsorbent.

[0032] With the attapulgite adsorbent prepared in this embodiment 2, the concentration is 20mg / L containing Cu 2+ The wastewater is subjected to adsorption treatment. Under the conditions that the dosage of the granular attapulgite adsorbent is 1g / L, the stirring speed of 250r / min and the adsorption time are 2h, the Cu-containing 2+ Cu in wastewater 2+ The removal...

Embodiment 3

[0034] A granular attapulgite adsorbent and a preparation method thereof. The concrete steps of its preparation method are:

[0035] Step 1, mixing water and attapulgite powder evenly, the mass ratio of water and attapulgite powder is 1: 0.7~0.9, to obtain muddy attapulgite;

[0036] Step 2, drying the prepared mud-like attapulgite at 100-110° C. for 8-12 hours, and breaking it into granular attapulgite with a particle size of 0.45-1.25 mm;

[0037] Step 3, then place the prepared granular attapulgite in a muffle furnace, and calcinate at 700-750° C. for 2-2.5 hours to prepare the granular attapulgite adsorbent.

[0038] With the attapulgite adsorbent prepared in this embodiment 3, the concentration is 20mg / L containing Cd 2+ The wastewater is subjected to adsorption treatment. Under the conditions that the dosage of the granular attapulgite adsorbent is 1g / L, the stirring speed of 250r / min and the adsorption time are 2h, the Cd-containing 2+ Cd in wastewater 2+ The remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com