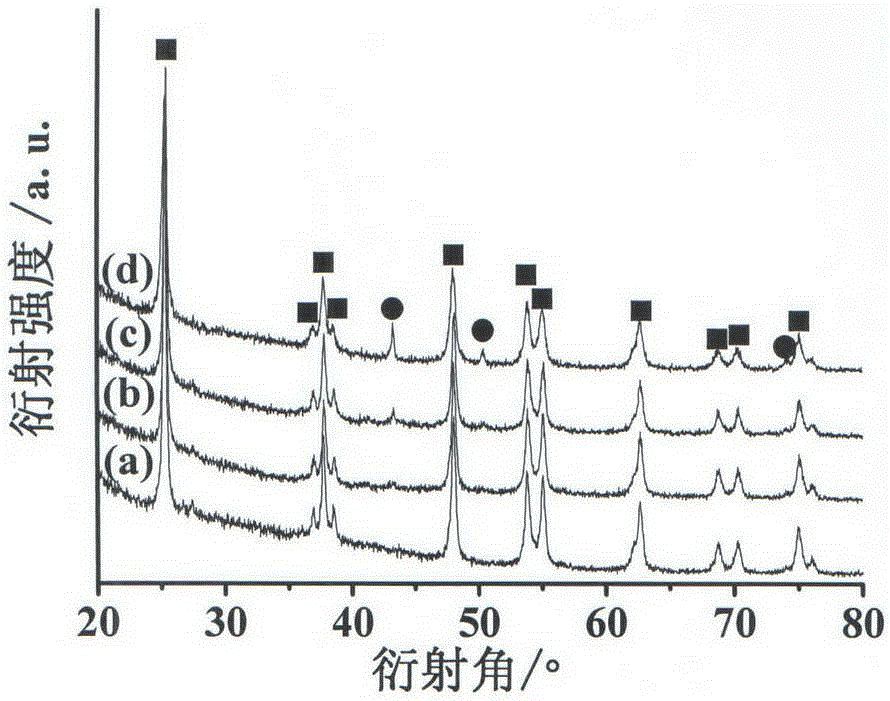

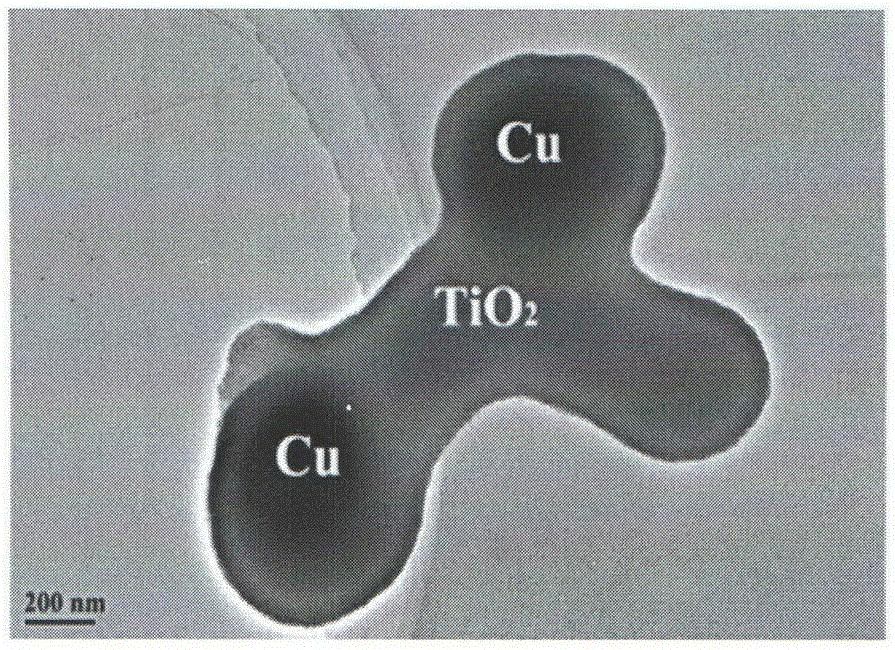

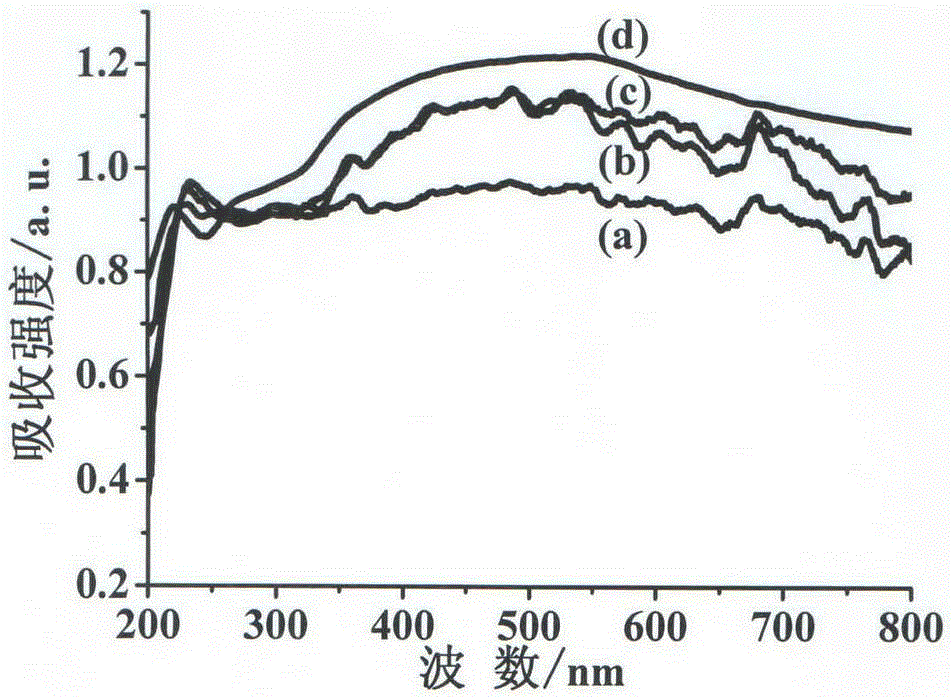

Preparation method and application of black TiO2 clad metal copper nanometer photocatalyst

A nano-photocatalyst, metal copper technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of easy oxidation of nano-copper metal particles, Achieve the effect of strong visible light catalytic reduction of CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] a. Weigh 2.41 grams of Cu(NO 3 ) 2 ·3H 2 O, 11.25 g Al(NO 3 ) 3 9H 2 O was dissolved in water to make 100ml solution, and another 6.4 grams of sodium carbonate was dissolved in 100ml solution, and the two solutions were added dropwise to 200ml distilled water under stirring, and the temperature was 80°C in a water bath to form a blue precipitate, which was washed with distilled water first 5 times, then washed once with absolute ethanol, dried in an oven at a temperature of 120°C, and then roasted at a temperature of 400°C for 3 hours to obtain a composite of copper oxide and aluminum oxide;

[0029] b. Disperse the compound into 100ml of 2mol / L sodium hydroxide solution, react for 12 hours, remove aluminum oxide in the compound, filter the resulting suspension, wash with distilled water, and dry at 80°C to obtain nano-copper oxide powder , and then weighed 0.0028 grams of nano-copper oxide powder, and reduced it with hydrogen at a temperature of 240 ° C for 3 hour...

Embodiment 2

[0032] a. Weigh 2.14 grams of Cu(NO 3 ) 2 ·3H 2 O, 11.25 g Al(NO 3 ) 3 9H 2 O was dissolved in water to make a 100ml solution, and another 6.7 grams of sodium carbonate was dissolved in a 100ml solution, and the two solutions were added dropwise to 200ml of distilled water under stirring, and the temperature was 80°C in a water bath to form a blue precipitate, which was first washed with distilled water 5 times, then washed once with absolute ethanol, dried in an oven at a temperature of 120°C, and baked in a muffle furnace at a temperature of 450°C for 2 hours to obtain a composite oxide of copper oxide and aluminum oxide;

[0033] b. Disperse the composite oxide into 100ml of 2mol / L sodium hydroxide solution, react for 12 hours, remove the aluminum oxide in the composite, and filter the resulting suspension, wash with distilled water, and dry at 80°C to obtain nano-copper oxide Powder, take 0.004 g of nano-copper oxide powder, and reduce it with hydrogen at a temperatur...

Embodiment 3

[0036] a. Weigh 2.14 grams of Cu(NO 3 ) 2 ·3H 2 O, 15.00 grams of Al(NO 3 ) 3 9H 2 O was dissolved in water to make a 100ml solution, and another 8.16 grams of sodium carbonate was dissolved in a 100ml solution, and the two solutions were added dropwise to 200ml of distilled water under stirring, and the temperature was 80°C in a water bath to form a blue precipitate, and then the precipitate was first used Distilled water 5 times, then washed once with absolute ethanol, dried in an oven at 120°C, and roasted in a muffle furnace at 500°C for 1 hour to obtain a composite oxide of copper oxide and aluminum oxide;

[0037] b. Disperse the obtained composite oxide into 100ml of 5mol / L sodium hydroxide solution and react for 12 hours to remove the aluminum oxide in the composite. The obtained suspension is filtered, washed with distilled water, and dried at 80°C to obtain nano Copper oxide powder, weigh 0.008 g of nano-copper oxide powder, and reduce it with hydrogen at a temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com