Device and method for accurately controlling local temperature of aluminum profile hot extrusion die

A technology of hot extrusion mold and local temperature, applied in the direction of manufacturing tools, metal extrusion, metal extrusion control equipment, etc., can solve the problems of profile surface quality degradation, easy failure, size out of tolerance, etc., to avoid indirect measurement Response hysteresis to mild temperature changes, effect of overcoming change hysteresis and inconsistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

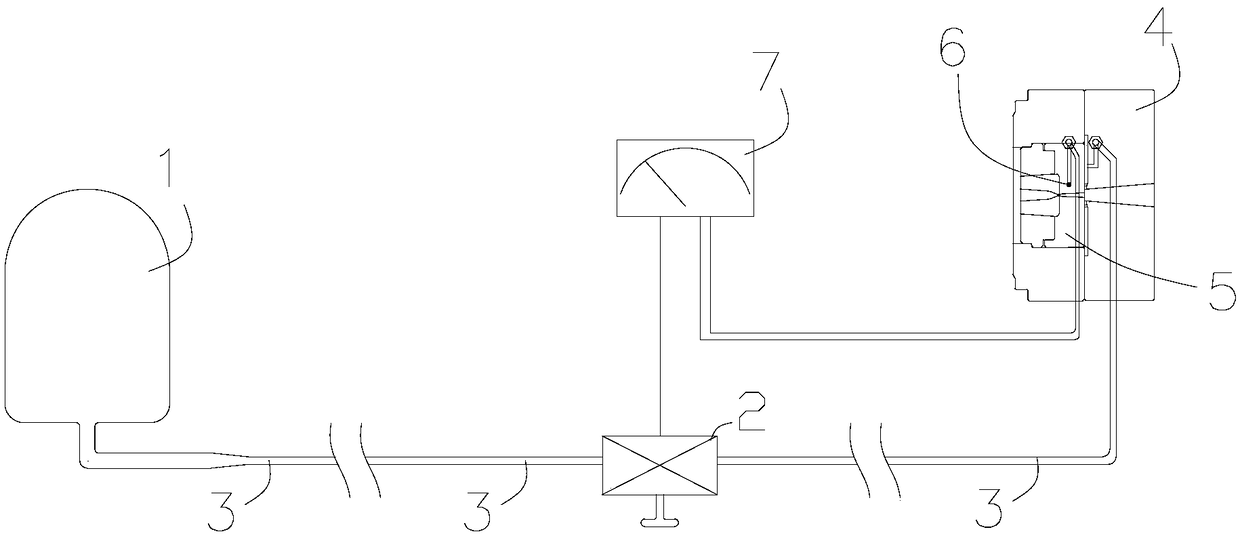

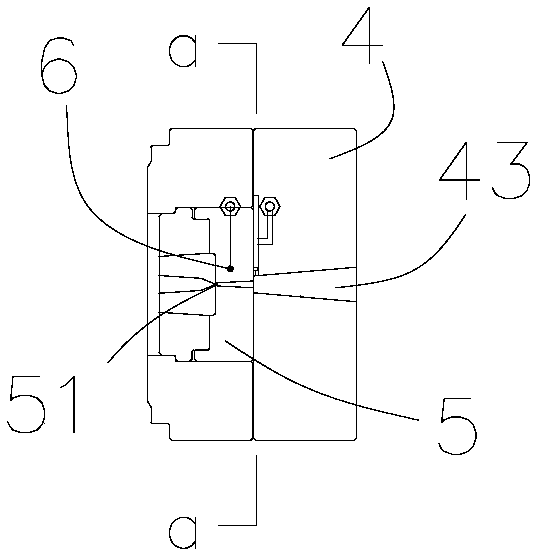

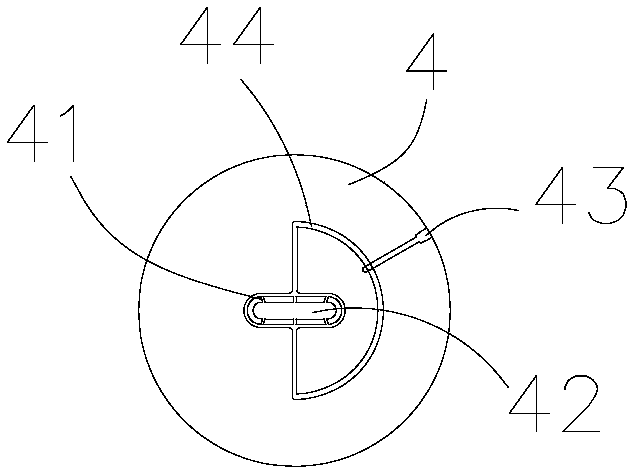

[0025] Such as Figure 1-3 As shown, the present invention provides a device for accurately controlling the local temperature of an aluminum profile hot extrusion die, including a liquid nitrogen tank 1, a low temperature control valve 2, a liquid nitrogen pipeline 3, a die pad 4, a die 5 and a temperature controller 7, and the die 5 is installed in the mold cushion 4, the liquid nitrogen pipeline 3 is connected between the liquid nitrogen tank 1 and the mold cushion 4 and is used to transport liquid nitrogen into the mold cushion 4, and the low temperature control valve 2 is set on the liquid nitrogen pipeline 3 and controls the liquid nitrogen The flow rate, the mold 5 is provided with a contact thermocouple 6, and the contact thermocouple 6 is connected to a temperature controller 7 through a compensation wire. The temperature controller 7 is electrically connected to the low temperature control valve 2 and sends a DC control signal to the low temperature control valve 2. B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com